Neat soap washing powder and preparing technique thereof

A production process and washing powder technology, applied in the direction of soap detergent composition, detergent composition, chemical instruments and methods, etc., can solve the problems of hard water resistance, poor solubility, poor detergency, etc., and achieve low production cost , easy to use, enhanced effect of detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

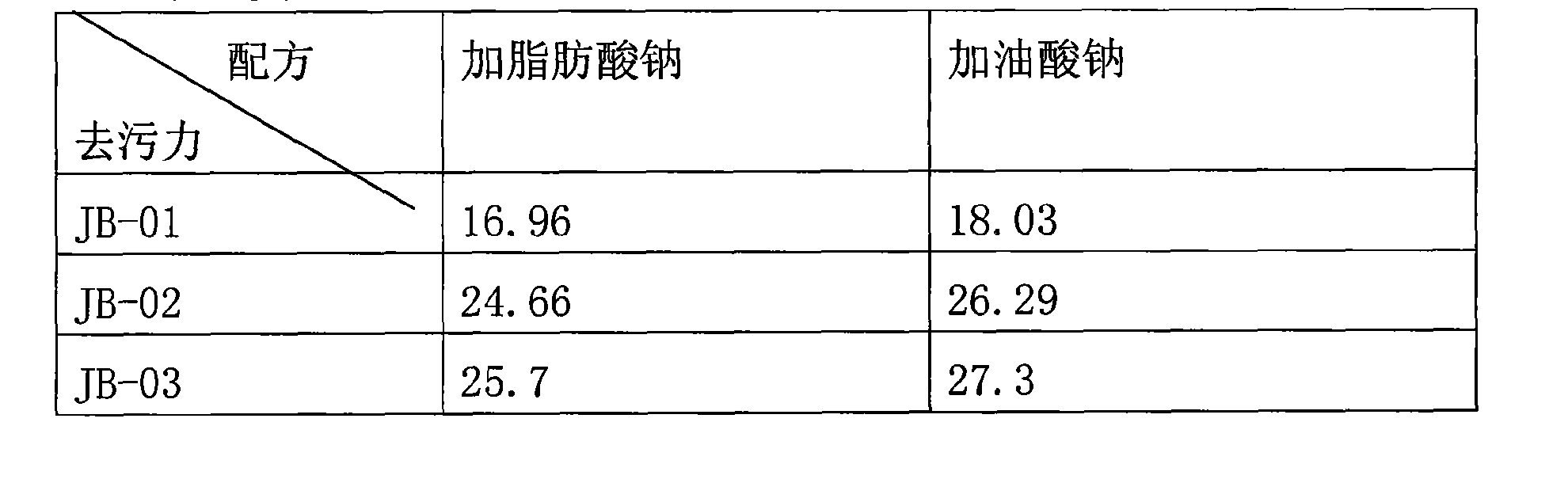

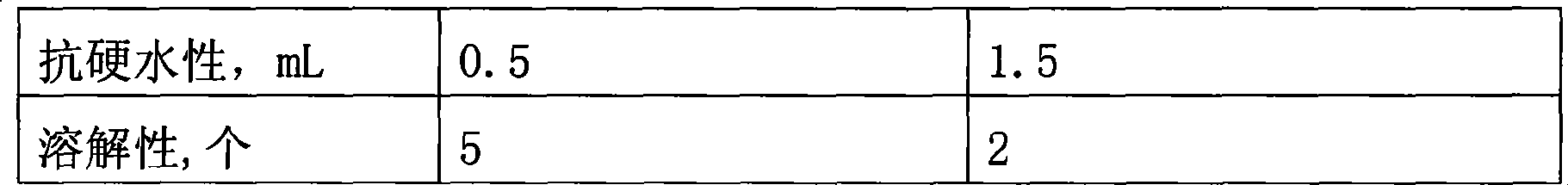

Embodiment 1

[0024] Embodiment 1, a kind of soap-based washing powder, is characterized in that: be made up of the raw material of following weight ratio,

[0025] 5 parts of surfactant, 40 parts of sodium oleate, 20 parts of detergent builder, 10 parts of auxiliary materials, 5 parts of filler sodium sulfate.

[0026] The surfactants used are anionic surfactant sodium dodecylbenzene sulfonate LAS, sodium α-olefin sulfonate AOS, ethoxylated alkyl sodium sulfate AES, C10-24 fatty acid soap and nonionic surfactant fat Any one of alcohol polyoxyethylene ether AEO-9 and fatty alcohol polyoxyethylene ether AEO-7 or a combination of two or more.

[0027] The sodium oleate used is obtained from oleic acid and sodium hydroxide.

[0028] The detergent builder is sodium carbonate, sodium tripolyphosphate, layered crystalline sodium disilicate, zeolite, sodium citrate, sodium silicate, sodium metasilicate, sodium p-toluenesulfonate, sodium perborate, sodium percarbonate Any one or a combination of ...

Embodiment 2

[0031] Embodiment 2, a kind of soap-based washing powder, is characterized in that: it is made up of the raw material of following weight ratio, and the number of parts represents

[0032] 30 parts of surfactant, 2 parts of sodium oleate, 70 parts of detergent builder, 0.1 part of auxiliary material, 50 parts of filler sodium sulfate

[0033] The surfactants used are anionic surfactant sodium dodecylbenzene sulfonate LAS, sodium α-olefin sulfonate AOS, ethoxylated alkyl sodium sulfate AES, C10-24 fatty acid soap and nonionic surfactant fat Any one of alcohol polyoxyethylene ether AEO-9 and fatty alcohol polyoxyethylene ether AEO-7 or a combination of two or more.

[0034] The sodium oleate used is obtained from oleic acid and sodium hydroxide.

[0035] The detergent builder is sodium carbonate, sodium tripolyphosphate, layered crystalline sodium disilicate, zeolite, sodium citrate, sodium silicate, sodium metasilicate, sodium p-toluenesulfonate, sodium perborate, sodium perca...

Embodiment 3

[0038] Embodiment 3, a kind of soap-based washing powder, is characterized in that: it is made up of the raw material of following weight ratio, and the number of parts represents

[0039] 20 parts of surfactant, 25 parts of sodium oleate, 45 parts of detergent builder, 5 parts of auxiliary materials, 30 parts of filler sodium sulfate,

[0040] The surfactants used are anionic surfactant sodium dodecylbenzene sulfonate LAS, sodium α-olefin sulfonate AOS, ethoxylated alkyl sodium sulfate AES, C10-24 fatty acid soap and nonionic surfactant fat Any one of alcohol polyoxyethylene ether AEO-9 and fatty alcohol polyoxyethylene ether AEO-7 or a combination of two or more.

[0041] The sodium oleate used is obtained from oleic acid and sodium hydroxide.

[0042] The detergent builder is sodium carbonate, sodium tripolyphosphate, layered crystalline sodium disilicate, zeolite, sodium citrate, sodium silicate, sodium metasilicate, sodium p-toluenesulfonate, sodium perborate, sodium per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com