Nylon 6/superfine calcium carbonate microparticle complex fiber and preparation method thereof

An ultra-fine calcium carbonate and composite fiber technology, applied in the chemical characteristics of fibers, melt spinning, rayon manufacturing, etc., can solve the problems of large equipment investment, dust pollution, high energy consumption, reduce production costs, heat resistance and resistance. Good grinding performance and the effect of promoting industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

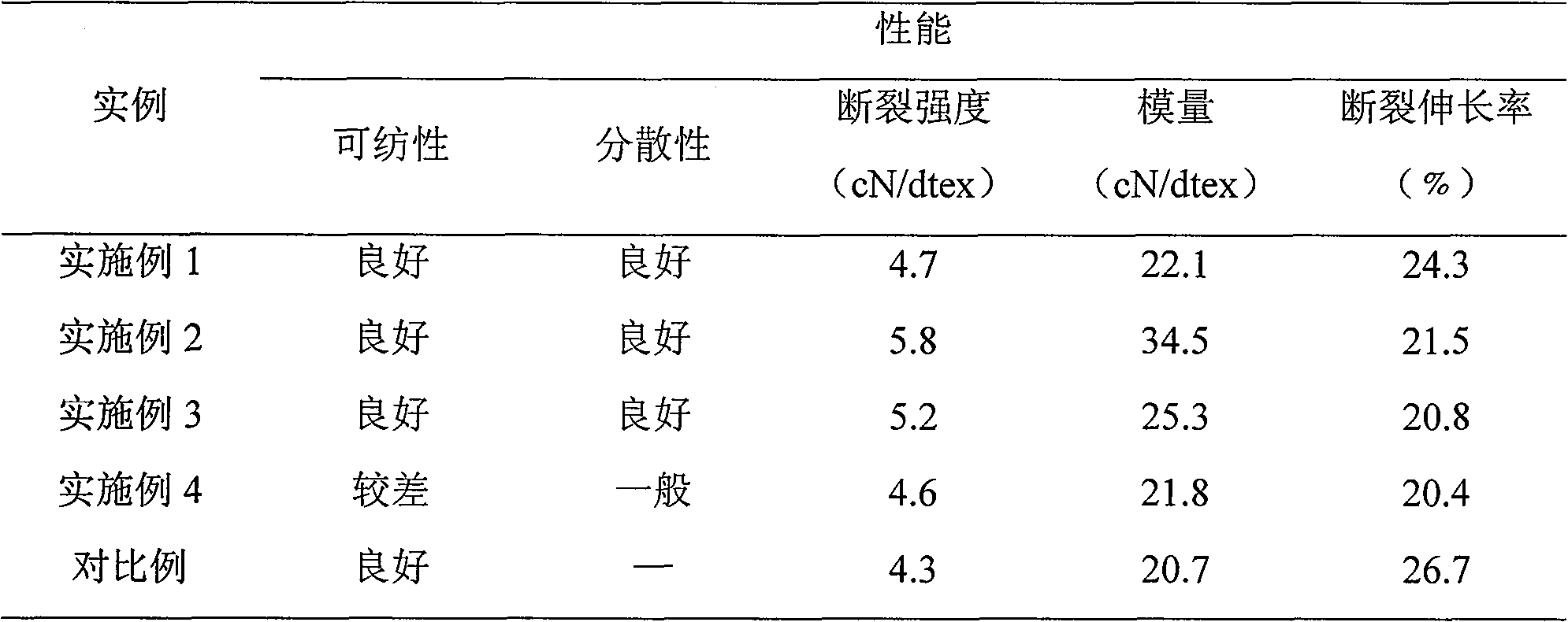

Examples

Embodiment 1

[0023] Put 1 part of superfine calcium carbonate particles and 0.02 part of surface treatment agent stearic acid into a high-speed mixer at a speed of 1000r / min, stir and mix for 25 minutes, then add 99 parts of nylon 6 slices, keep stirring and heat up, Stop heating when the temperature reaches 145°C, continue stirring and cooling, and discharge to room temperature. The prepared mixture was vacuum-dried at 90°C for 4 hours, then the mixture was put into a twin-screw extruder, and melt-spun at 280°C at a spinning speed of 700m / min. The stretching temperature is 95°C for the second drafting and heat setting, and the total drafting ratio is 3 times, so as to obtain the finished silk.

Embodiment 2

[0025] Put 3 parts of superfine calcium carbonate particles and 0.06 parts of surface treatment agent stearic acid into a high-speed mixer at a speed of 3000r / min, stir and mix for 20 minutes, then add 97 parts of nylon 66 slices, keep stirring and heat up. Stop heating when the temperature reaches 145°C, continue stirring and cooling, and discharge to room temperature. The prepared mixture was vacuum-dried at 90°C for 4 hours, then the mixture was put into a screw extruder, and melt-spun at 310°C, the spinning speed was 700m / min, and the winding wire was drawn by heat The temperature is between 210°C for the second drafting and heat setting, and the total drafting ratio is 6 times, so as to obtain the finished silk.

Embodiment 3

[0027] Put 5 parts of superfine calcium carbonate particles and 0.1 part of surface treatment agent stearic acid into a high-speed mixer at a speed of 3000r / min, stir and mix for 20 minutes, then add 95 parts of nylon 6 slices, keep stirring and heat up, Stop heating when the temperature reaches 145°C, continue stirring and cooling, and discharge to room temperature. The prepared mixture was vacuum-dried for 4 hours at a temperature of 90°C, then the mixture was put into a screw extruder, and melt-spun at 280°C, the spinning speed was 700m / min, and the winding wire was drawn by heat The temperature is 95°C for the second drafting and heat setting, and the total drafting ratio is 3 times, so as to obtain the finished silk.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com