Nano composite modifying agent for improving weathering resistance performance powder paint and preparation method thereof

A powder coating and nano-composite technology, which is applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problem that the amount of leveling agent is easy to float to the surface of the coating film, so as to improve the anti-ultraviolet aging performance, Improved leveling and excellent cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

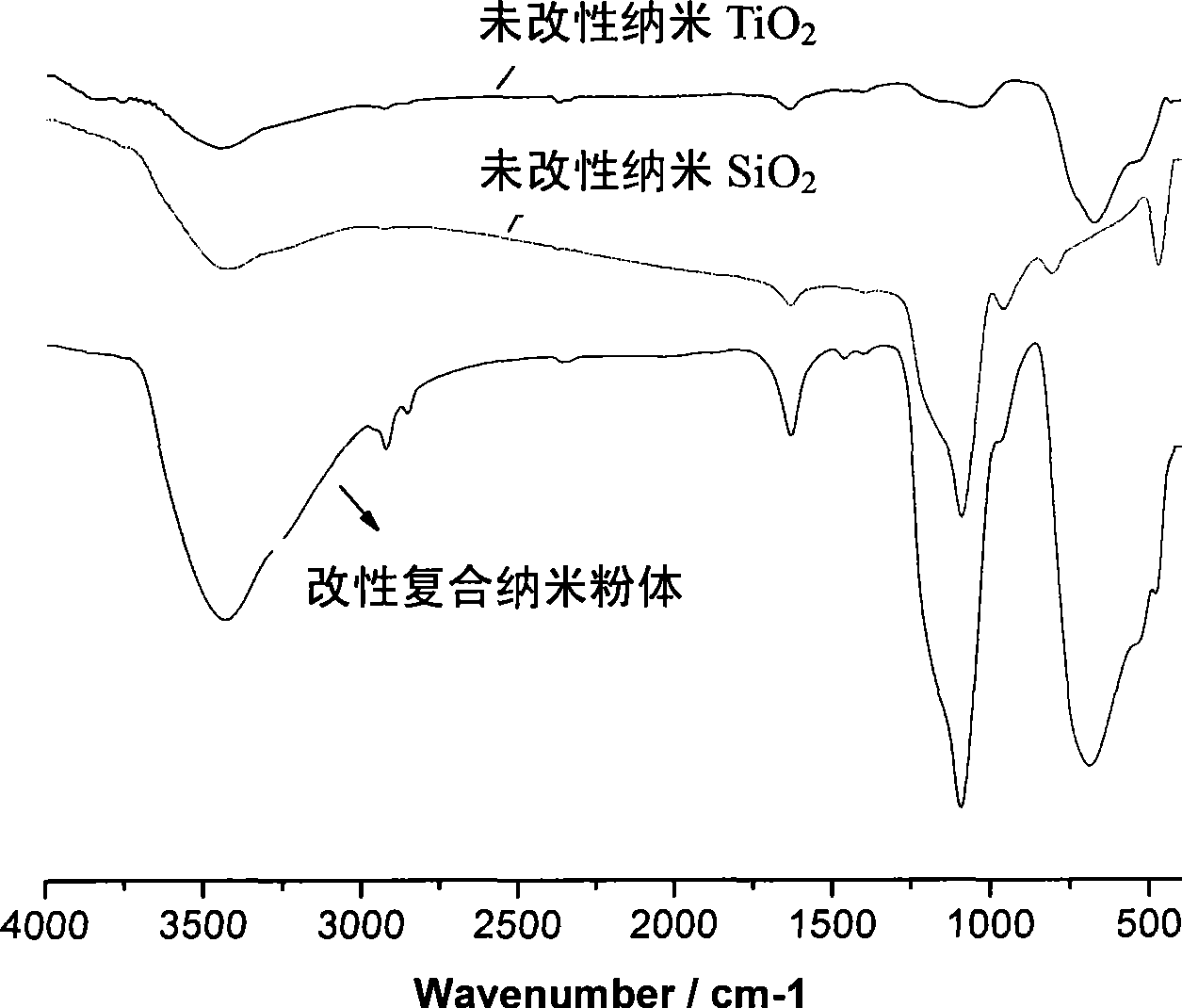

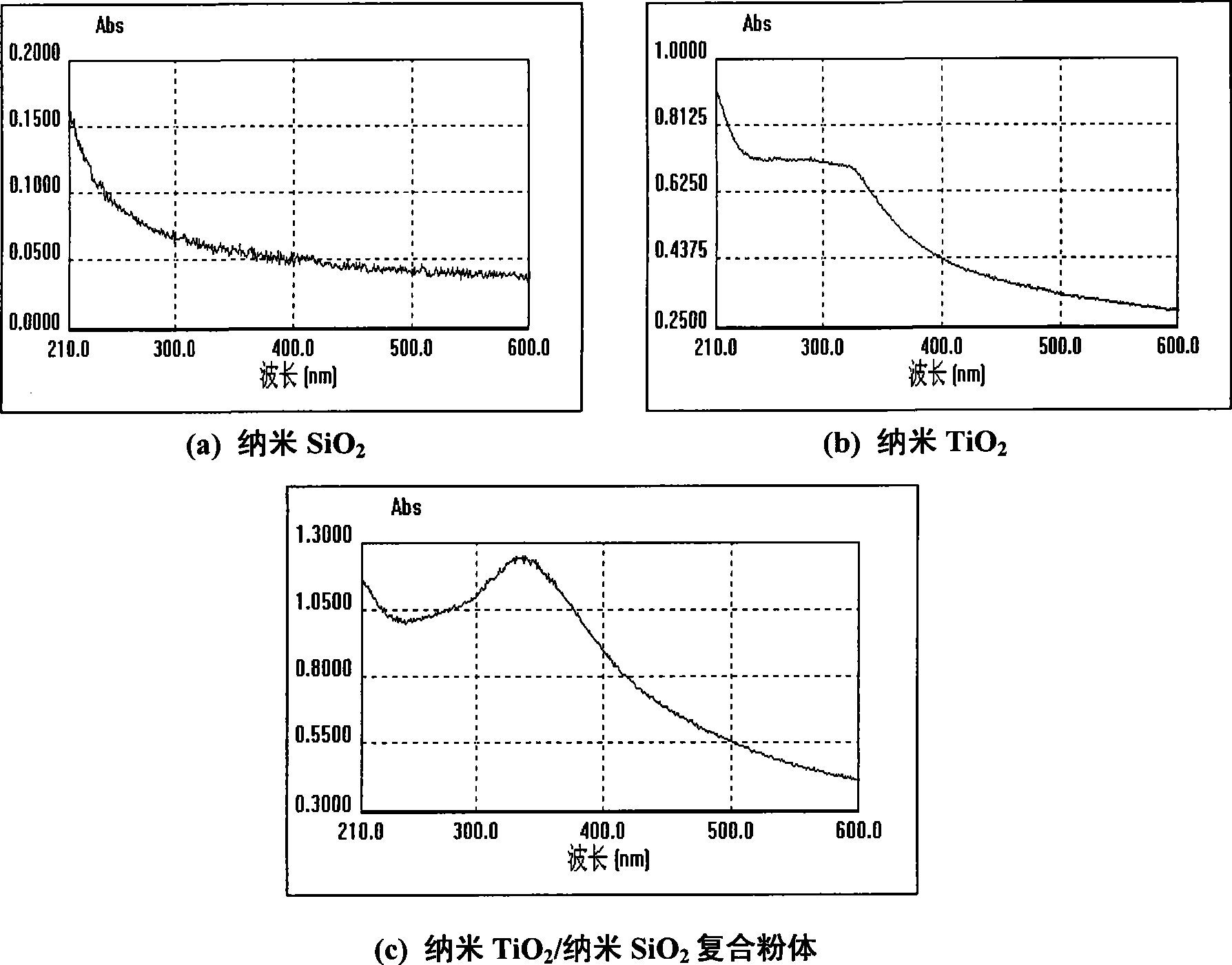

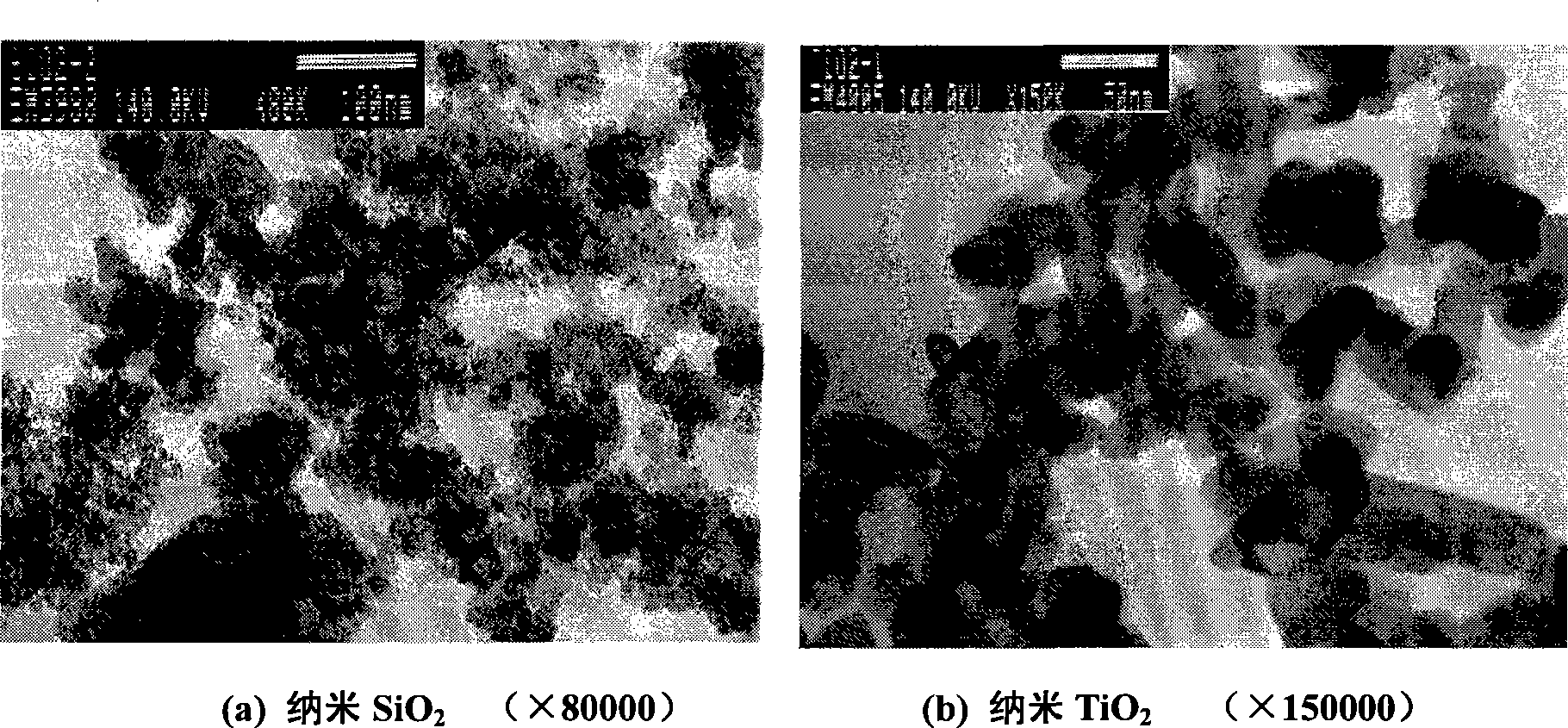

Embodiment 1

[0044] Mix 2g of silane coupling agent with 1000g of absolute ethanol, heat to 80-100°C and stir evenly, then add nano-TiO 2 100g of powder was stirred at high speed for 2.5 hours, then the mixture was suction filtered, dried at 110°C, ground and sieved. Nano-TiO modified by silane coupling agent 2 Mix 100g of powder, 25g of organic ultraviolet light absorber, and 100g of leveling agent in a high-speed mixer, add 200g of acrylic resin to the mixture, continue to mix at high speed, and finally convey the mixed material to the twin-screw extruder with a feeder In the process, melt mixing, extrusion, pulverization and granulation are carried out.

Embodiment 2

[0046] Mix 3g of aluminate coupling agent with 1500g of absolute ethanol, heat to 80-100°C and stir evenly, then add nano-TiO 2 and nano-SiO 2 (The ratio of the two is 4:1) 120g of composite powder, stirred at high speed for 3 hours, then the mixture was suction filtered, dried at 110°C, ground and sieved. Put 120g of nano-composite powder modified by aluminate coupling agent, 40g of composite powder of organic ultraviolet light absorber and quencher (the ratio of the two is 1:1), and 160g of leveling agent in a high-speed mixer Mix evenly, add 320g of polyester resin to the mixture, continue to mix at high speed, and finally transport the mixed material to a twin-screw extruder with a feeder for melt mixing, extrusion, pulverization and granulation.

Embodiment 3

[0048] Mix 3g of titanate coupling agent with 1500g of absolute ethanol, heat to 80-100°C and stir evenly, then add nano-TiO 2 and nano-SiO 2 (The ratio of the two is 4:1) 120g of composite powder, stirred at high speed for 4 hours, then the mixture was suction filtered, dried at 110°C, ground and sieved. 120g of nanocomposite powder modified by titanate coupling agent, 60g of composite powder of organic ultraviolet light absorber, quencher and hindered amine light stabilizer (the ratio of the three is 1:1:1), flow 200g of the leveling agent is mixed uniformly in a high-speed mixer, and 400g of polyester resin is added to the mixture, and the high-speed mixing is continued. Finally, the mixed material is transported to a twin-screw extruder by a feeder, and melted, mixed, extruded and granulated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com