Thermoplastic resin membrane wrapping control-releasing fertilizer using sulfur as base coat

A thermoplastic resin, coated controlled-release fertilizer technology, applied in the form of fertilizer, fertilization device, fertilizer mixture, etc., can solve the problems of unsatisfactory water blocking performance, unsatisfactory nutrient controlled release, unsatisfactory controlled release performance, etc., to achieve improvement The effect of sulfur film properties, nutrient controlled release performance improvement, and extensive application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

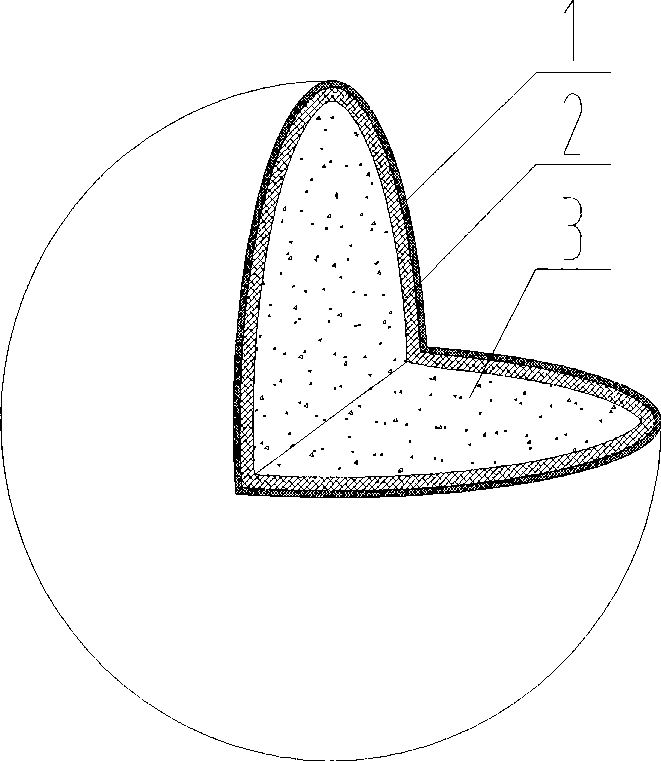

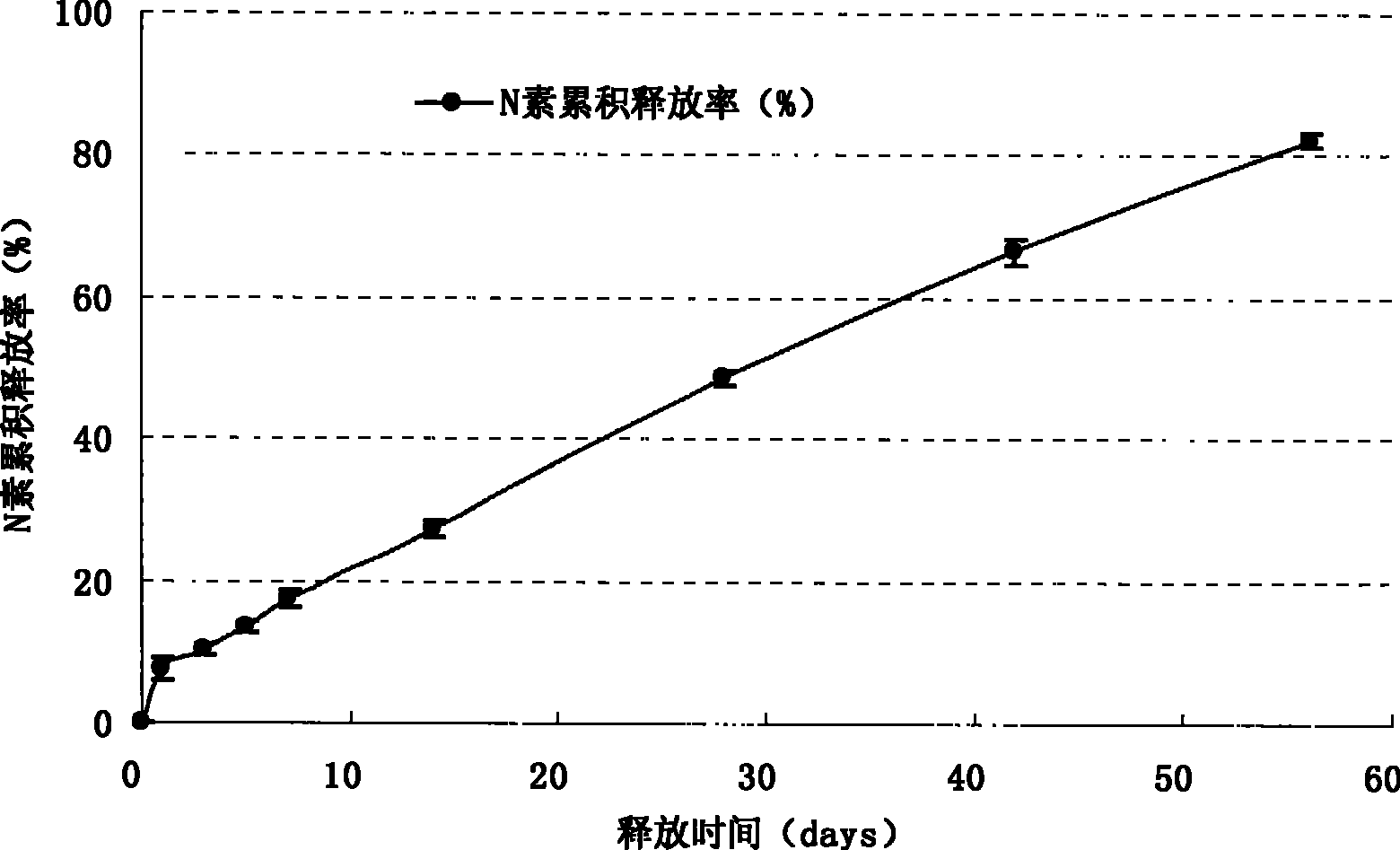

[0023] Embodiment 1 Production of thermoplastic resin-coated controlled-release fertilizer products with sulfur as the base coat for 2 months of controlled-release period

[0024] (1) Preheat 1000kg of urea granules (1.5-5.0mm in diameter) to 75°C in a drum.

[0025] (2) Spray 100kg of liquid sulfur at a temperature of 140°C onto the moving urea particles, the liquid sulfur droplets spread evenly on the surface of the moving urea particles, and quickly solidify into a sulfur film, continuously spraying liquid sulfur, gradually forming a uniform and continuous sulfur film membrane.

[0026] (3) Dissolve 20kg of reclaimed polyethylene resin in 200kg of turpentine at 100°C, and add 10kg of starch to prepare a coating solution, spray the coating solution onto the moving sulfur-coated fertilizer particles in a drum, and heat it in 85°C hot air Driven by the driving force, the solvent sprayed on the surface of the moving sulfur-coated fertilizer is quickly volatilized and taken awa...

Embodiment 2

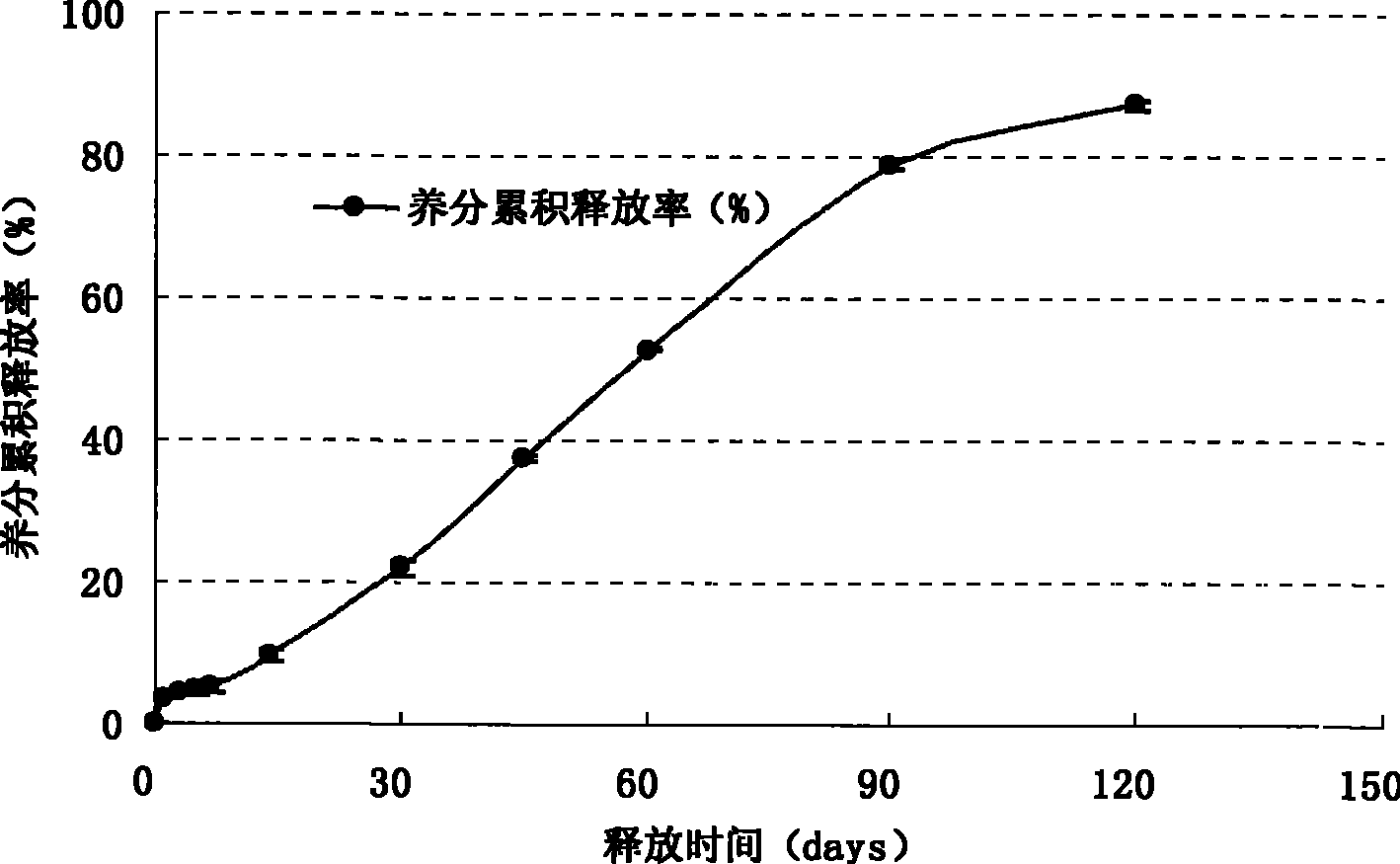

[0027] Example 2 Production of thermoplastic resin-coated controlled-release fertilizer with controlled-release period of 9 months

[0028] (1) Preheat 1000kg of compound fertilizer (15-15-15) particles (1.5-5.0mm) to 80°C in a drum.

[0029] (2) Spray 140kg of liquid sulfur at a temperature of 150°C onto the moving urea granules. The liquid sulfur mist spreads evenly on the surface of the moving urea granules and quickly solidifies into a sulfur film. Continuously spraying liquid sulfur gradually forms a uniform and continuous sulfur film. membrane.

[0030] (3) 30kg of reclaimed polyethylene resin is dissolved in 450kg of turpentine at 110°C to prepare a coating solution, and in a drum, the coating solution is sprayed onto the moving sulfur-coated fertilizer particles, driven by 95°C of hot air, The solvent sprayed on the surface of the moving sulfur-coated fertilizer is quickly volatilized and taken away, and the polyethylene resin is wrapped on the sulfur-coated fertilize...

Embodiment 3

[0031] Example 3 Production of thermoplastic resin-coated controlled-release fertilizer with a controlled-release period of 10 months

[0032] (1) Preheat 1000kg of ammonium sulfate, diammonium phosphate, and ammonium bicarbonate granular fertilizer to 80°C in a drum.

[0033](2) Spray 140kg of liquid sulfur at a temperature of 145°C on the moving urea particles, the liquid sulfur droplets spread evenly on the surface of the moving urea particles, and quickly solidify into a sulfur film, continuously spraying liquid sulfur, gradually forming a uniform and continuous sulfur film membrane.

[0034] (3) 40kg of reclaimed polyethylene resin is dissolved in 450kg of turpentine at 110°C to prepare a coating solution, and the coating solution is sprayed onto the moving sulfur-coated fertilizer particles in a drum, driven by 90°C of hot air, The solvent sprayed on the surface of the moving sulfur-coated fertilizer is quickly volatilized and taken away, and the polyethylene resin is w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com