Carboxymethyl wood flour water absorbent and preparation method thereof

A technology of carboxymethyl wood powder and water absorbing agent, applied in the field of organic polymer compounds, can solve the problems of high utilization rate and low cost of wood, and achieve the effects of high utilization rate, low cost and omitting the washing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

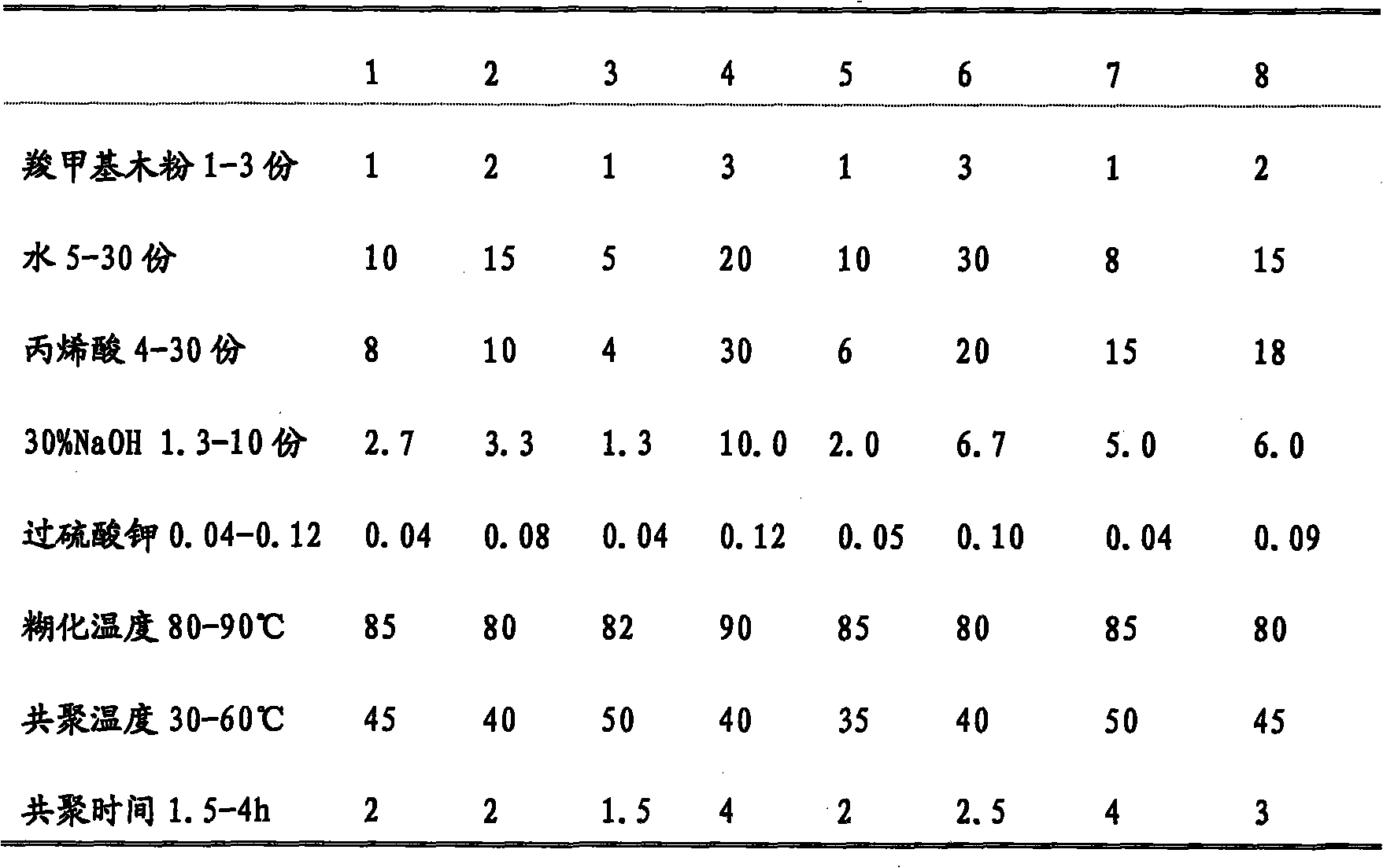

[0018] Embodiment 1 (see the corresponding raw materials and parts by weight of Example 1 in the table): add 1 part by weight of carboxymethyl wood powder (the same below) in the reactor, add 10 parts of water, fill the reactor with nitrogen to remove oxygen, and heat up to Stir at 85°C for 0.5h to generate carboxymethyl wood flour gelatin, then add 8 parts of acrylic acid, add 2.7 parts of NaOH solution with a concentration of 30% to adjust the neutralization degree to 60%, add 0.04 parts of potassium persulfate to control the copolymerization reaction Stir and react for 2 hours at a temperature of 45°C to obtain a light yellow paste, which is dried to a constant weight and crushed into a 40-mesh powder, sealed and packaged.

[0019] The corresponding raw materials and parts by weight and reaction conditions of Examples 2-8 are shown in the table, and all the other methods are the same as in Example 1.

[0020] The core idea of the present invention is to use carboxymethyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com