Fume denitration composite catalyst using titanium-base ceramics as carrier and preparation method thereof

A monolithic catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of easy pulverization and poor wear resistance of catalysts, Achieve the effect of low cost, good thermal stability and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

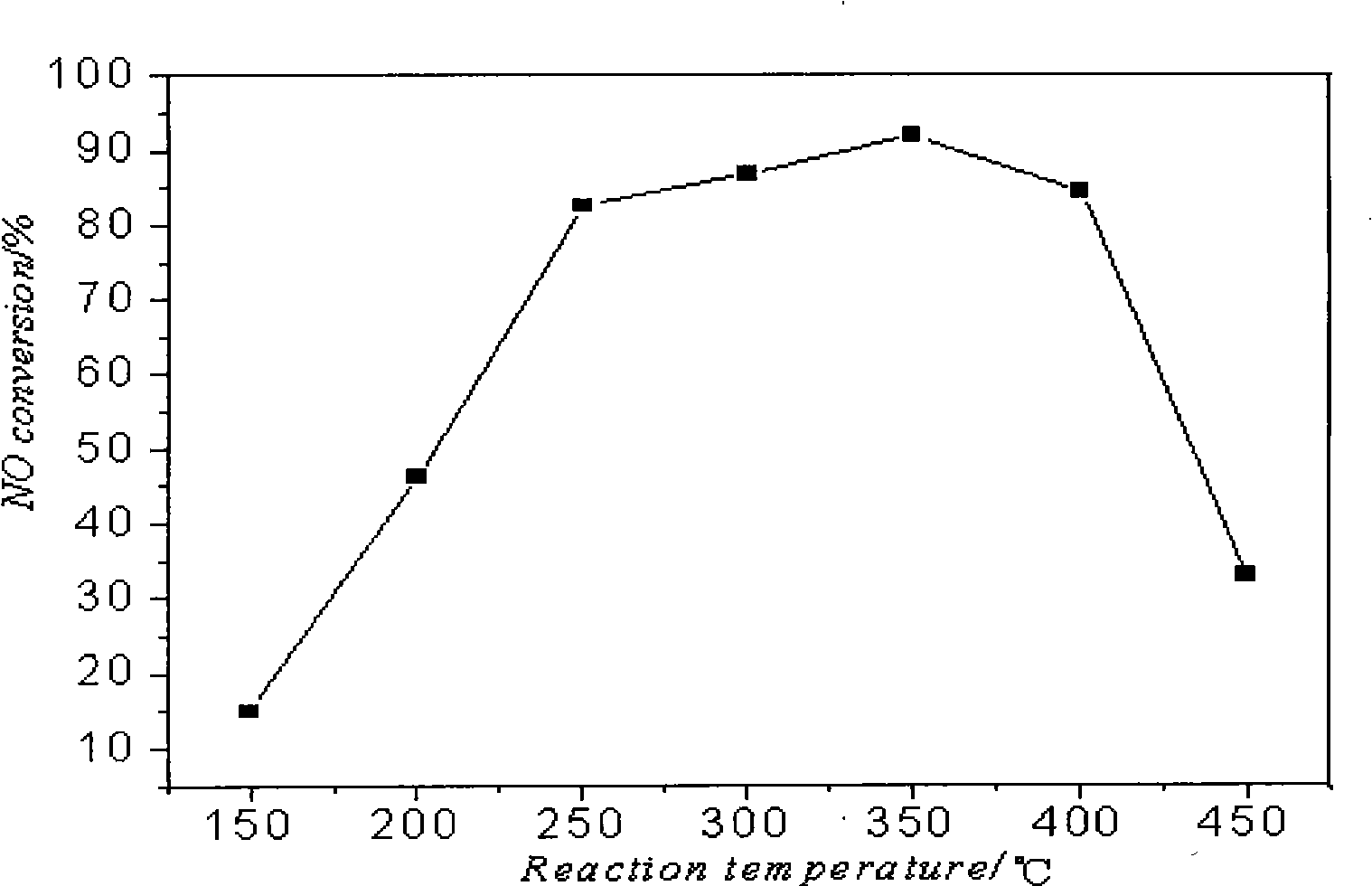

Image

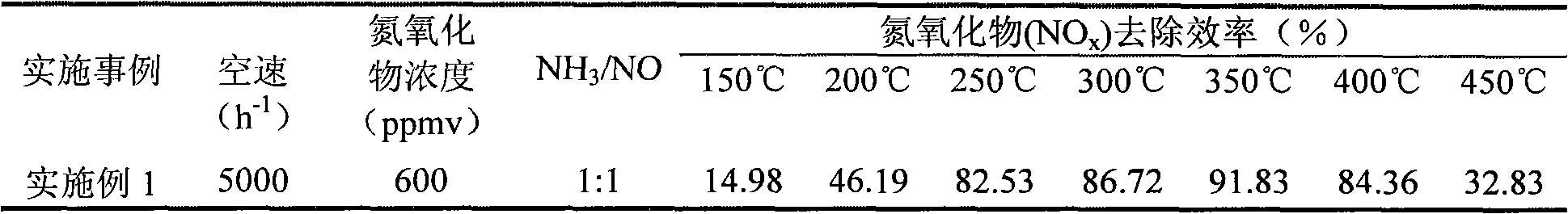

Examples

Embodiment 1

[0027] (1) SiO 2 Sol preparation

[0028] Measure 100ml TEOS, 30ml ethanol and 80ml water with a graduated cylinder and put them into a round bottom flask, then add glacial acetic acid catalyst at 0.085 times the amount of TEOS substance, stir evenly with a glass rod, and put it into an electronic constant temperature water bath. Condensate and reflux at a constant temperature of 70°C for 50 minutes to obtain stable SiO 2 Sol.

[0029] (2) SiO 2 Application of the second carrier layer

[0030] Immerse 8g of the pretreated silica porcelain in the SiO prepared in step (1) 2 Put it in the sol for 30 minutes, take it out and dry it in the shade for 24 hours, then bake it in a muffle furnace at 500°C for 2 hours, repeat dipping, drying and roasting (drying and roasting system remains unchanged) once until the required carrier load is reached, that is, the coating is complete SiO 2 The second carrier layer, based on the mass of the first carrier, has a mass percentage of 8%; ...

Embodiment 2

[0037] (1) SiO 2 Sol preparation

[0038] Measure 100ml TEOS, 24ml ethanol and 84ml water into a round bottom flask with a graduated cylinder, then add nitric acid catalyst at 0.08 times the amount of TEOS, stir evenly with a glass rod, and put it into an electronic constant temperature water bath. Condensate and reflux at a constant temperature of 65°C for 50 minutes to obtain stable SiO 2 Sol.

[0039] (2) SiO 2 Application of the second carrier layer

[0040] 8g pretreated ATS ceramics were impregnated in the SiO prepared in step (1) 2 Put in the sol for 15 minutes, take it out and dry it in a blast drying oven at 80°C for 10 hours, then bake it in a muffle furnace at 450°C for 2 hours, and then coat SiO 2 The second carrier layer, based on the mass of the first carrier, has a mass percentage of 5.1%;

[0041] (3) Preparation of active component impregnation solution

[0042] 10g Ce(NO 3 ) 3 .6H 2 Ce(NO 3 ) 3 solution;

[0043] (4) Active CeO 2 load

[0044] ...

Embodiment 3

[0046] (1) SiO 2 Sol preparation

[0047] Measure 100ml TEOS, 33ml ethanol and 63ml water into a round bottom flask with a graduated cylinder, then add sulfuric acid catalyst at 0.08 times the amount of TEOS, stir evenly with a glass rod, and put it into an electronic constant temperature water bath. Condensate and reflux at a constant temperature of 75°C for 50 minutes to obtain stable SiO 2 Sol.

[0048] (2) SiO 2 Application of the second carrier layer

[0049] Immerse 8g of the pretreated cordierite porcelain in the SiO prepared in step (1) 2 Put it in the sol for 20 minutes, take it out and dry it in a blast drying oven at 100°C for 9 hours, then heat it in a muffle furnace at 350°C for 3 hours and bake it, repeat dipping, drying and roasting (the drying and roasting system remains unchanged) once until the required carrier is reached loading, i.e. coated SiO 2 The second carrier layer, based on the mass of the first carrier, has a mass percentage of 9.4%;

[0050]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com