Coal rock solid gas coupling fine observation mechanics loading device

A technology of meso-mechanics and loading device, which is used in measurement devices, scientific instruments, material analysis by optical means, etc. It can solve the problems of single stress state and other problems, so as to achieve the effect of good reliability, simple structure and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

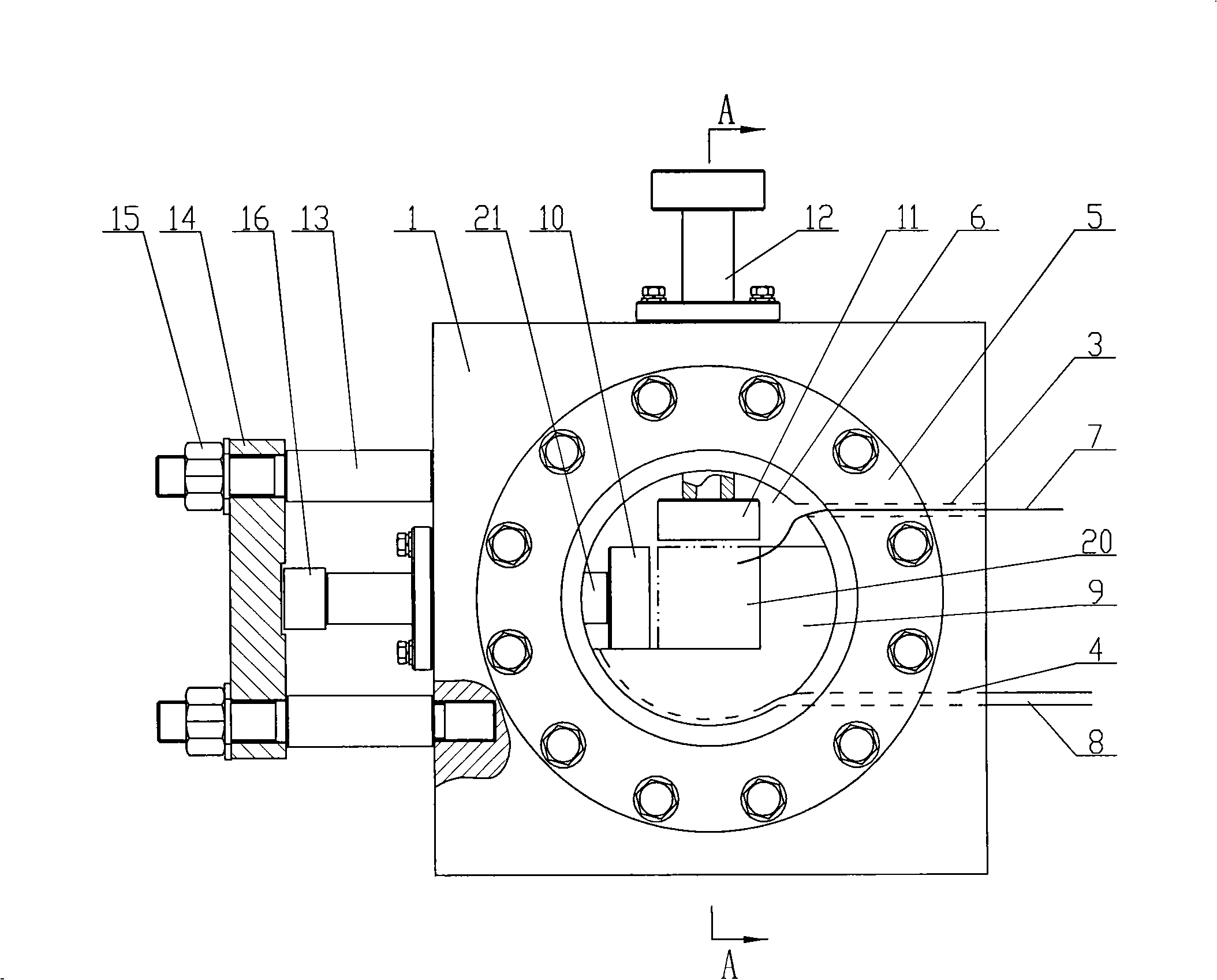

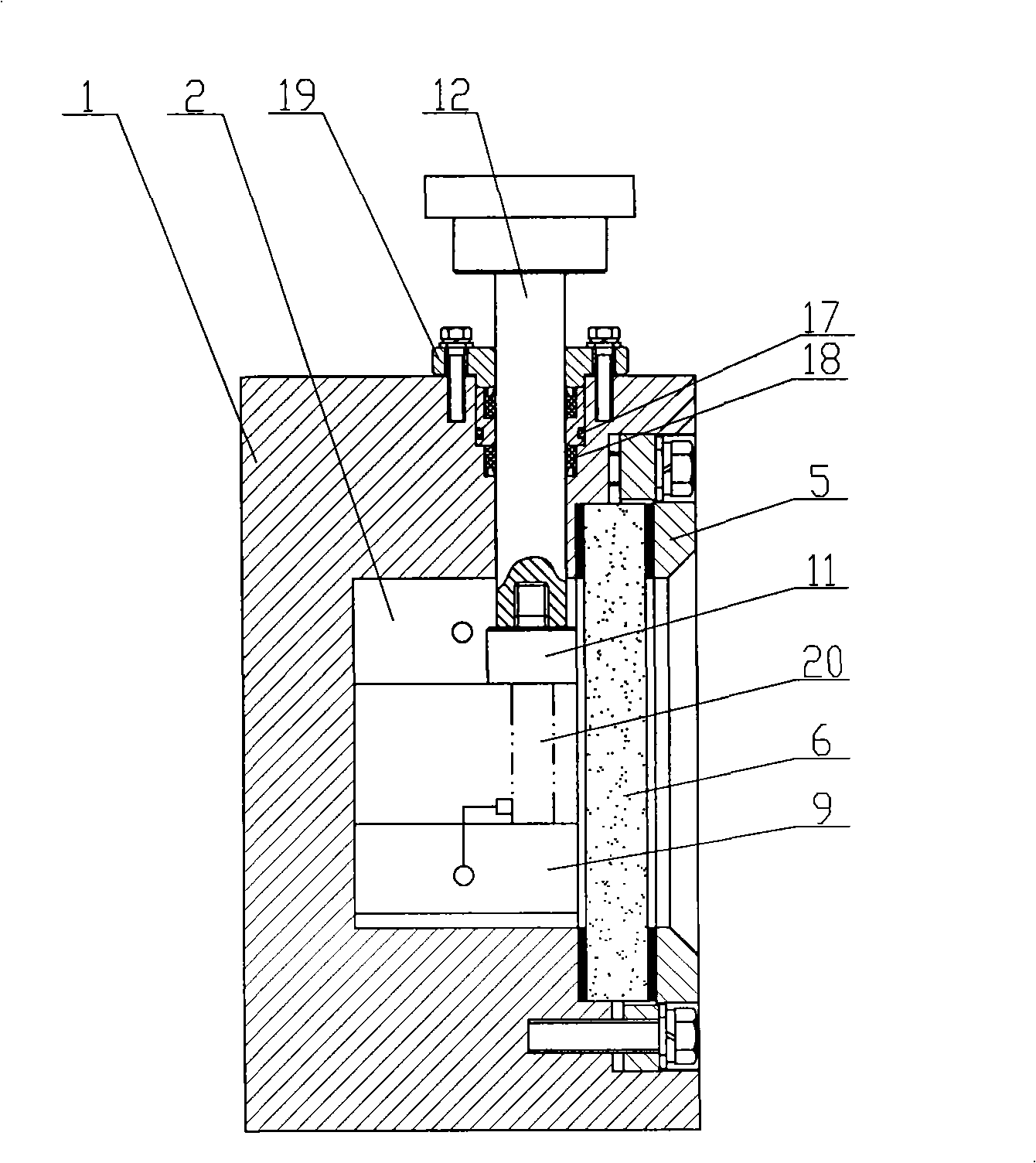

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0022] like figure 1 , figure 2 As shown, the test body 1 is a cube structure, and a test cavity 2 is opened on the test body 1. The opening of the test cavity 2 is located on the front of the test body 1. The test cavity 2 is circular and has a stepped shape with a small inside and a large outside. . The transparent viewing mirror 6 and the gland 5 are located at the opening of the test chamber 2, that is, in the large-diameter section, wherein the transparent viewing mirror 6 is disc-shaped, and the inner surface of the transparent viewing mirror 6 is limited by the step surface in the test chamber 2. The transparent sight glass 6 and the test body 1 are sealed by an O-ring, and the gland 5 is circular, and the gland 5 is set on the outer edge of the transparent sight glass 6, and is connected to the test body by screws evenly distributed on the circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com