Hyaluronic acid modified polycaprolactone/polylactic acid three-dimensional stephanoporate compound stent and preparation

A technology of polycaprolactone and hyaluronic acid, which is applied in the direction of conjugated synthetic polymer rayon, fiber processing, filament/thread forming, etc., can solve the problems such as no similar or similar patent reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

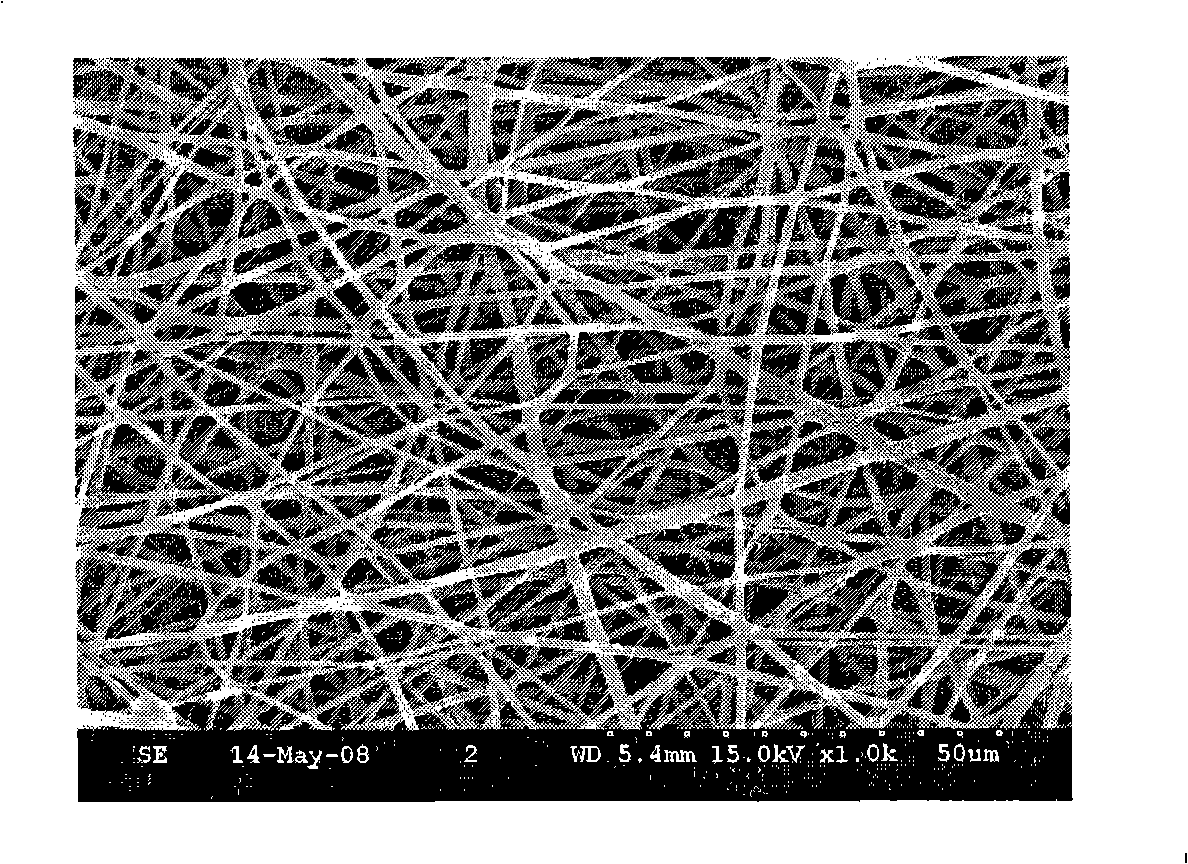

[0031] Using chloroform as a co-solvent, dissolve polymer PCL with a molecular weight of 50,000 and a melting point of 58-60°C, and polymer PLA with an average molecular weight of 100,000 and a melting point of 150-170°C in a ratio of 60:40 In a co-solvent, stir evenly to make a transparent and uniform solution, then electrospin to make an electrospun fiber mat, dry it in a vacuum oven, remove the residual solvent, take it out, stack it and fill it in a mold with a specific shape. The temperature of the vacuum oven was set at 63°C, and the mold was placed in the vacuum oven at a constant temperature for 20 minutes before being taken out, cooled and demoulded, then subjected to plasma modification, then soaked in hyaluronic acid solution, and then freeze-dried to obtain Scaffold material for tissue engineering with specific shape and good performance. The fiber mat fiber diameter measured by scanning electron microscope and Photoshop software is 2000±300nm, and the contact angl...

Embodiment 2

[0033]Using a mixed solvent of chloroform and DMF as a co-solvent, the high polymer PCL with a molecular weight of 100,000 and a melting point of 58-60°C, and the high-molecular PLA with an average molecular weight of 10,000 and a melting point of 150-170°C were mixed in a ratio of 40:60. Dissolve the ratio in the co-solvent, stir evenly, make a transparent solution, electrospin to make electrospun fiber felt, put it in a vacuum oven to dry, take it out, stack it and fill it in a mold with a specific shape, and put it in a vacuum oven The temperature was set at 63°C, and the mold was placed in a vacuum oven at a constant temperature for 35 minutes before being taken out, cooled and demolded, and then subjected to plasma modification, then soaked in hyaluronic acid solution, and then freeze-dried to obtain a specific Scaffold material for tissue engineering with good shape and good performance. The fiber mat fiber diameter measured by scanning electron microscope and Photoshop ...

Embodiment 3

[0035] Using a mixed solvent of tetrahydrofuran and acetone as a co-solvent, the polymer PCL with a molecular weight of 100,000 and a melting point of 58-60°C and the polymer PLA with a molecular weight of 10,000 and a melting point of 150-170°C are mixed in a ratio of 80:20 Dissolve in a co-solvent, stir evenly to make a transparent solution, electrospin to make an electrospun fiber mat, dry it in a vacuum oven, remove the residual solvent, take it out, stack it and fill it in a mold with a specific shape. The temperature of the vacuum oven is set at 60°C, the mold is placed in the vacuum oven at a constant temperature for 40 minutes, and then taken out, cooled and demoulded, then subjected to plasma modification, then soaked in hyaluronic acid solution, and then freeze-dried to obtain Scaffold material for tissue engineering with specific shape and good performance. The fiber mat fiber diameter measured by scanning electron microscope and Photoshop software is 3500±200nm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com