Method for preparing carbon nano-tube array on particle interior surface

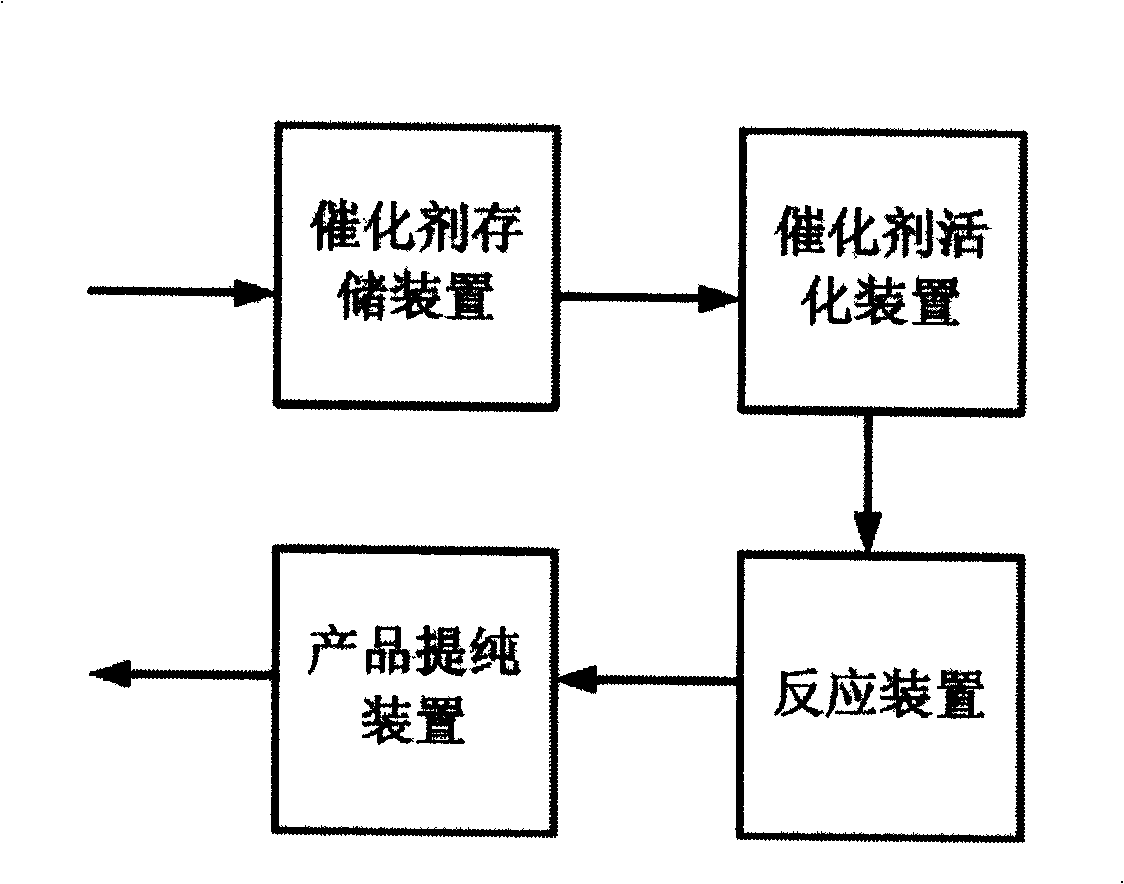

A carbon nanotube array and intra-particle technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems affecting continuous growth, shape change, etc., and achieve easy process, equipment, and simple operation , continuous easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

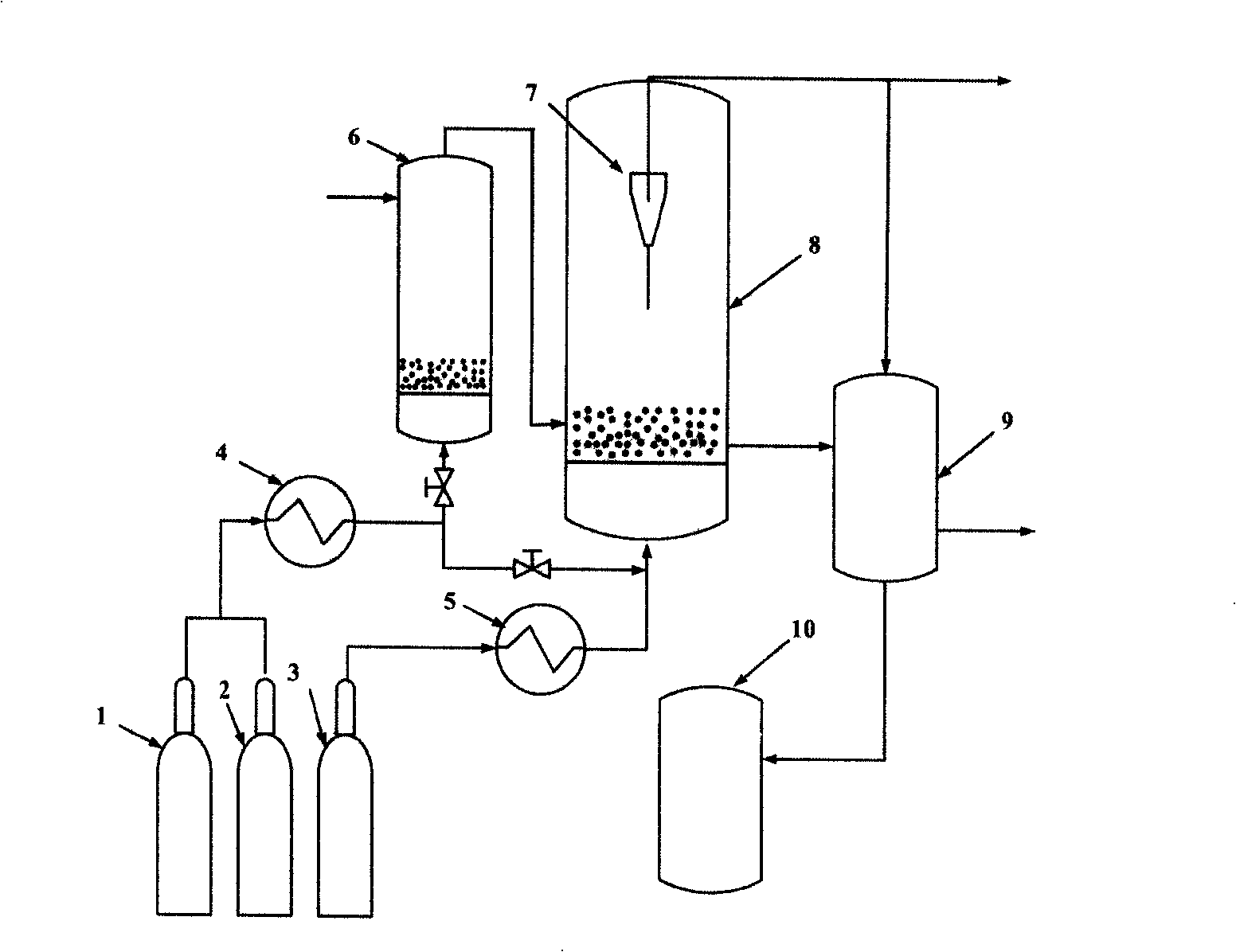

[0049] The Fe / Mo system is used as the catalyst active component, and the vermiculite is used as the catalyst carrier. Vermiculite is a natural layered aluminosilicate compound composed of tens of thousands of vermiculite sheets superimposed on each other. The vermiculite sheets superimposed on each other form the inner surface of vermiculite particles with a radius of curvature not less than 500nm. figure 2 It is a process flow diagram of an embodiment of the invention. The process contains carrier gas nitrogen storage tank 1, hydrogen storage tank 2, carbon source gas ethylene storage tank 3, carrier gas and reducing gas preheater 4, carbon source gas preheater 5, catalyst activation reactor 6, carbon nano The tube array growth reactor has a built-in cyclone separator 7 , a carbon nanotube array growth reactor 8 , a product purification device 9 , and a product storage tank 10 . Weigh 10kg of Fe(NO 3 ) 3 9H 2 O and 1kg (NH 4 )Mo 7 o 24 4H 2 O, put it into 100L of de...

Embodiment 2

[0052] The Ni / Mo system is used as the catalyst active component, and the vermiculite is used as the catalyst carrier. Weigh 1000g of Ni(NO 3 ) 2 ·6H 2 O and 100g of (NH 4 )Mo 7 o 24 4H 2 O, put it into 10L of deionized water to make a mixed solution, weigh 2000g of vermiculite with an average particle size of 120μm, put it in it, soak it at 60°C for 14h, filter, wash, and dry to obtain the Ni-loaded solution on the inner surface. / Mo active component of vermiculite catalyst. Put 200g of the catalyst into a fixed-bed activation reactor with a diameter of 30mm, and at 500°C, flow a mixed gas of carbon monoxide and nitrogen to carry out the reduction reaction, wherein carbon monoxide and nitrogen are mixed at a volume ratio of 1:5, and the reduction air 0.3 hours -1 ; Send the reduced catalyst to a fluidized bed reactor with an inner diameter of 150 mm through a high flow rate of nitrogen, the reaction temperature is 750 ° C, and a mixed gas of ethylene, hydrogen, and ni...

Embodiment 3

[0054] The Co / Mo system is used as the catalyst active component, and the vermiculite is used as the catalyst carrier. Weigh 1000g of Co(NO 3 ) 2 ·6H 2 O and 100g of (NH 4 )Mo 7 o 24 4H 2 O, put it into 10L of deionized water to make a mixed solution, weigh 2000g of vermiculite with an average particle size of 120μm into it, soak it at 80°C for 14h, filter, wash, and dry to obtain a solution loaded with Co on the inner surface. / Mo active component of vermiculite catalyst. Put 200g of the catalyst into a fluidized bed activation reactor at 750°C, feed a flowing mixed gas of hydrogen and argon to carry out the reduction reaction, wherein hydrogen and argon are mixed at a volume ratio of 1:20, and the reduction space velocity is 1 Hour -1 ; The catalyst after reduction is sent to the fluidized bed reactor (I) that internal diameter is 250mm, and temperature of reaction is 650 ℃, feeds the mixed gas of ethylene and nitrogen in the reactor, and gas volume ratio is ethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com