Sublimating crystallizing device

A technology of crystallization device and crystallization tube, which is applied in the field of chemical equipment, can solve the problems of changing the crystallization matrix, the inability to introduce target impurity molecules, and the inconvenient removal of crystallization products, so as to avoid the effect of shape damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

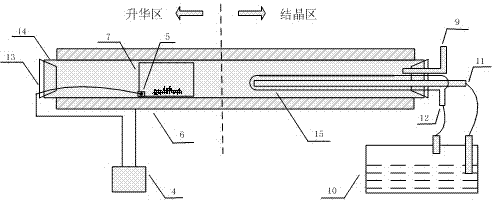

[0028] Example 1: Vacuum sublimation crystallization

[0029] Such as figure 1 As shown, put about 1g of β-succinic acid crystal powder into the loading tube 7, weigh the total weight as m0, put the thermocouple into the temperature measuring tube 5, and move the loading tube 7 to the sublimation zone of the thermostatic tube 14 The middle part of the middle part, cover the rubber stopper 13, place the glass sheet above the crystallization tube 15, adjust the temperature controller 4, set the heating temperature to 180°C, turn on the vacuum pump connected to the air release pipe 9, turn on the circulation constant temperature tank 10, and keep it until the set temperature Set the temperature at 95°C, and the material in the loading tube 7 is heated and sublimated into a gas under reduced pressure. When the hot air flow passes through the glass sheet above the crystallization tube 15, the temperature of the hot air flow drops, and the formed supersaturated steam slowly flows on...

Embodiment 2

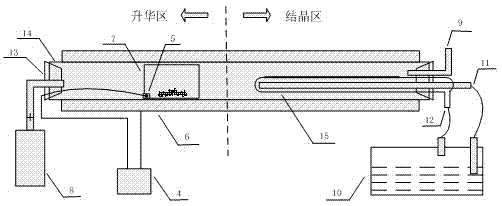

[0030] Example 2: Carrier gas flow sublimation crystallization

[0031] Such as figure 2 As shown, about 1g of pyrene crystal powder is loaded into the loading tube 7, and the total weight is called m0. The thermocouple is placed in the temperature measuring tube 5, and the loading tube 7 is moved to the middle part of the sublimation zone of the thermostatic tube 14. Cover the rubber stopper 13, connect the carrier gas cylinder 8 (nitrogen), and fix the nitrogen flow rate at 20 ml / min. Place the glass flake or aluminum foil above the crystallization tube 15, adjust the temperature controller 4, set the heating temperature to 140°C, connect the air release pipe 9 to the atmosphere, open the circulation constant temperature tank 10, keep the set temperature at 35°C, and adjust the flow regulator The material in the loading tube 7 is heated and sublimated into a gas under a nitrogen flow, and when the steam flows through the glass sheet or aluminum foil above the crystallizati...

Embodiment 3

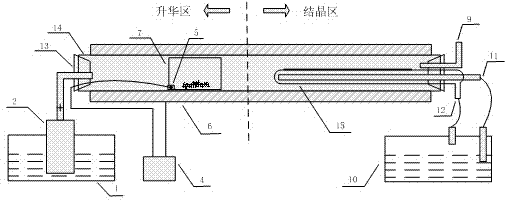

[0032] Example 3: Sublimation crystallization intervened by target impurities

[0033] Such as image 3 As shown, put about 1g of β-succinic acid crystal powder into the loading tube 7, weigh the total weight as m0, put the thermocouple into the temperature measuring tube 5, and move the loading tube 7 to the sublimation zone of the thermostatic tube 14 The middle part of the middle part, cover the rubber stopper 13, connect the material storage 2 (the target impurity is isopropanol solvent), open the constant temperature tank 1 to maintain a certain temperature to ensure that the evaporation pressure of isopropanol remains constant, and place the glass sheet in the crystallization Above the pipe 15, adjust the temperature controller 4, set the heating temperature to 180° C., turn on the vacuum pump connected to the air release pipe 9, maintain a certain degree of vacuum, and ensure that the flow rate of the flow regulator is fixed. Open the circulating constant temperature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com