A method for rapidly preparing ultrafine porous fibers

A porous fiber and whole body technology is applied in the field of rapid preparation of ultra-fine through body porous fibers, which can solve the problems of less improvement of the specific surface area of the fiber, and achieve the effects of high production efficiency, obvious porous characteristics and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

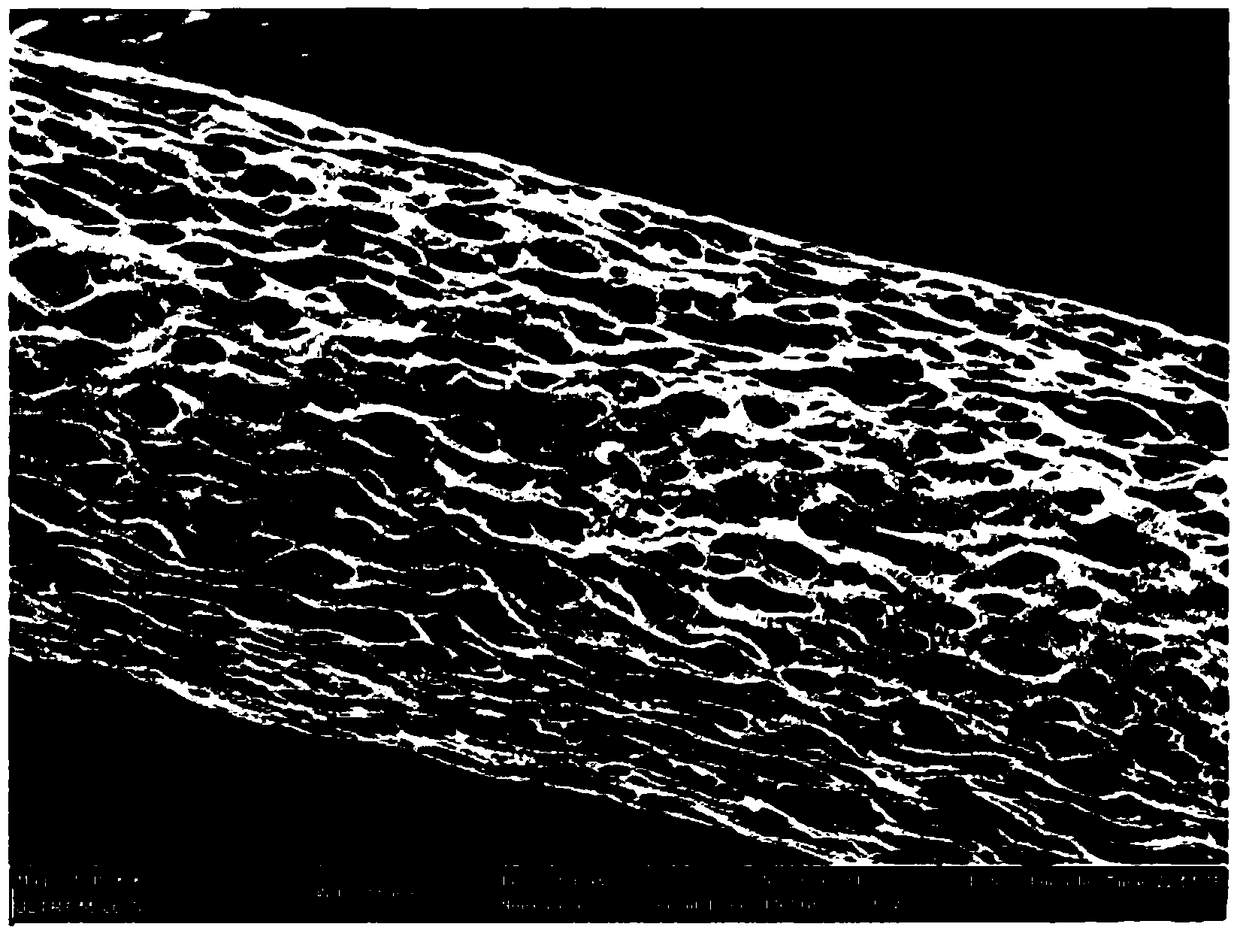

[0036] Add a certain amount of ethyl cellulose to a mixed solvent of 7mL ethanol and 3mL water, stir at room temperature to obtain a uniform solution, add a small amount of polyvinylpyrrolidone to the solution, and continue stirring at room temperature to obtain a transparent spinning solution. Wherein ethyl cellulose: the mass ratio of polyvinylpyrrolidone is 9:1. The spinning liquid is injected into the spinneret, and centrifugal spinning is carried out under the conditions of a rotating speed of 3000 rpm and a receiving distance of 10 cm to obtain ultrafine porous fibers throughout the body. The SEM image is as follows figure 1 , 2 shown.

Embodiment 2

[0038] Add a certain amount of ethyl cellulose to a mixed solvent of 8mL ethanol and 2mL water, stir at room temperature to obtain a uniform solution, add a small amount of polyvinylpyrrolidone to the solution, and continue stirring at room temperature to obtain a transparent spinning solution. Wherein ethyl cellulose: the mass ratio of polyvinylpyrrolidone is 8:2. The spinning liquid is injected into the spinneret, and centrifugal spinning is carried out under the conditions of a rotating speed of 3000 rpm and a receiving distance of 10 cm to obtain ultrafine porous fibers throughout the body. The SEM image is as follows image 3 , 4 shown.

Embodiment 3

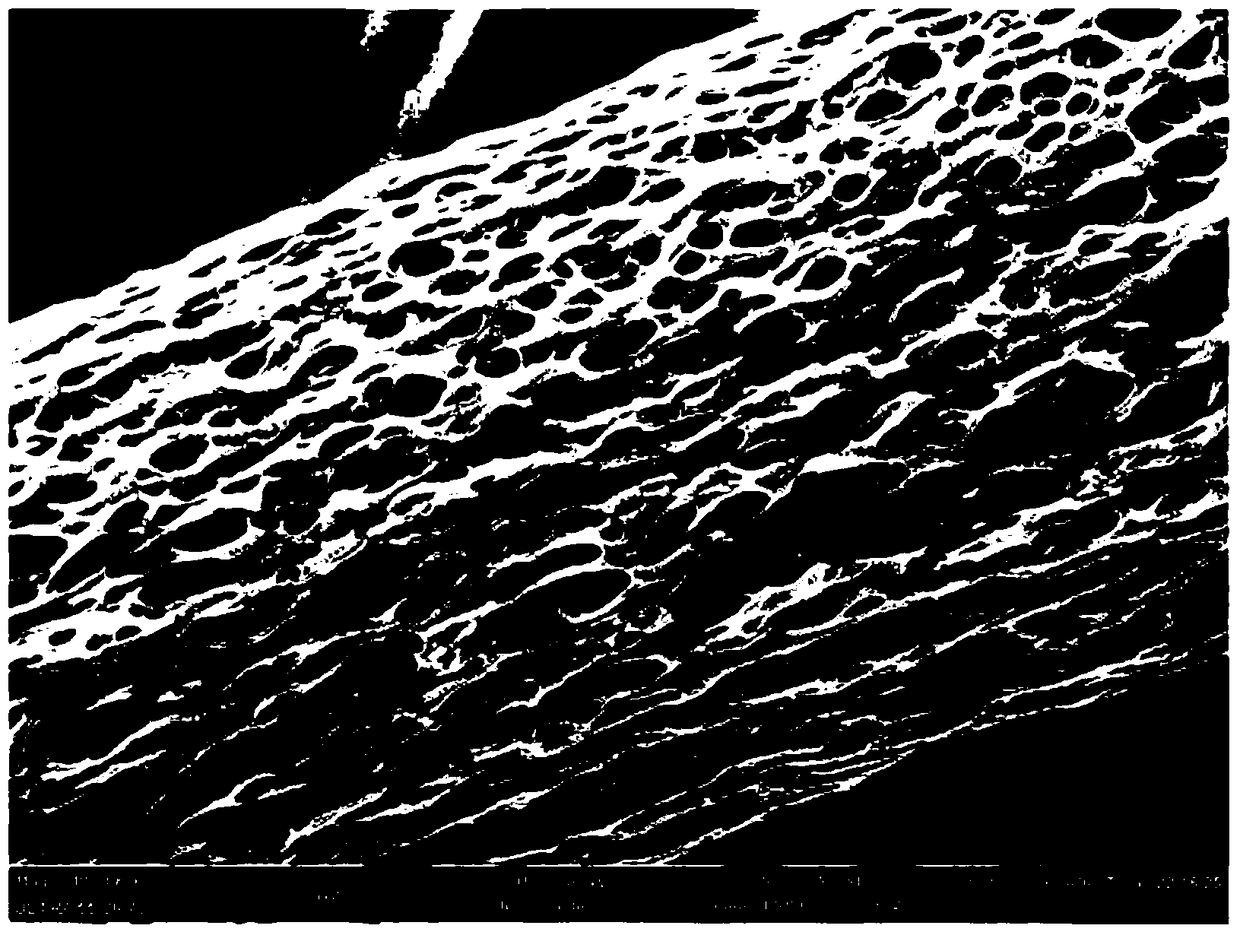

[0040] Add a certain amount of ethyl cellulose to a mixed solvent of 9mL ethanol and 1mL water, stir at room temperature to obtain a uniform solution, add a small amount of polyvinylpyrrolidone to the solution, and continue stirring at room temperature to obtain a transparent spinning solution. Wherein ethyl cellulose: the mass ratio of polyvinylpyrrolidone is 6:4. The spinning liquid is injected into the spinneret, and centrifugal spinning is carried out under the conditions of a rotating speed of 3000 rpm and a receiving distance of 10 cm to obtain ultrafine porous fibers throughout the body. The SEM image is as follows Figure 5 , 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com