Middle-temperature energy-saving leadless solder paste special for tuners

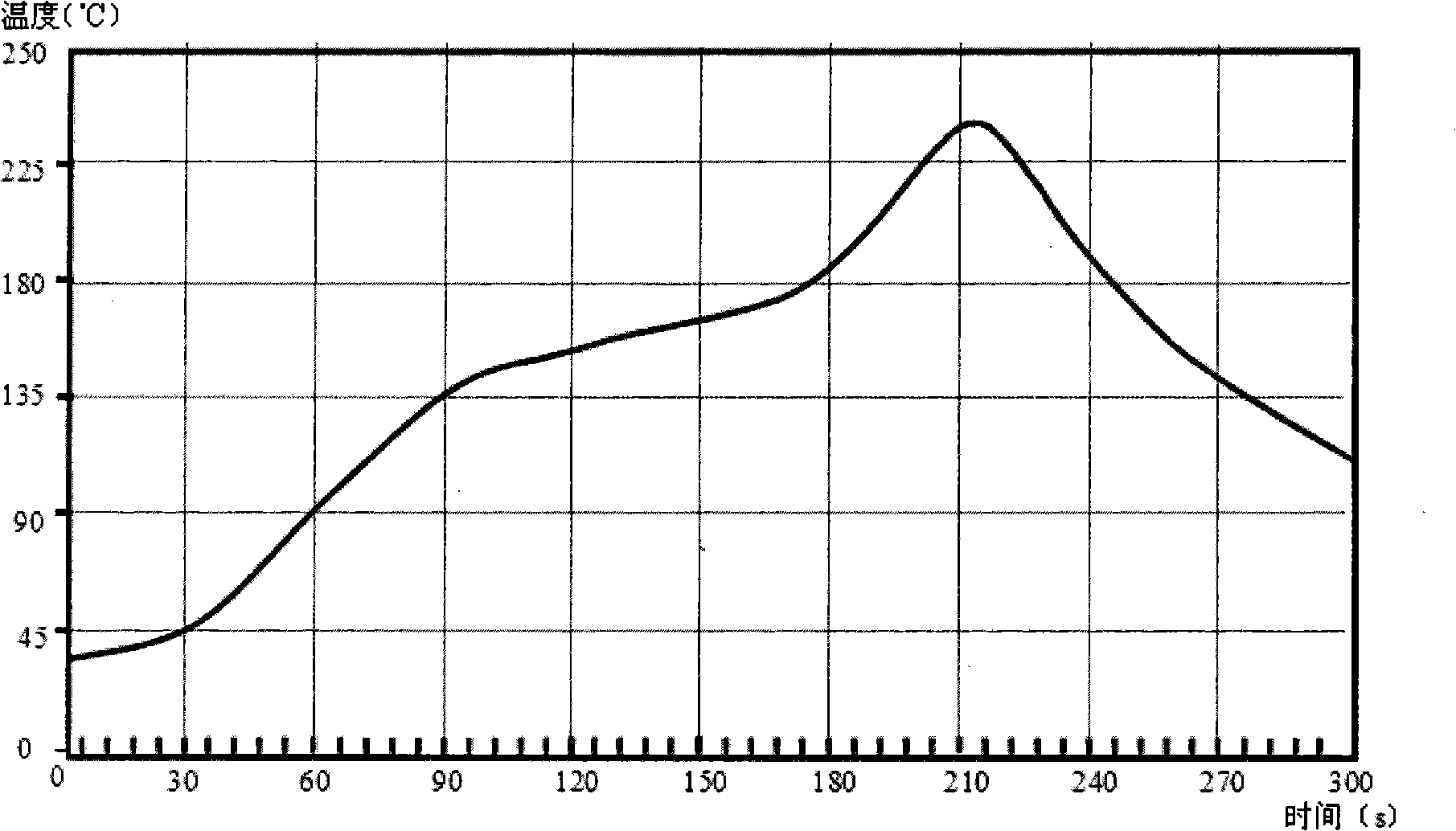

A lead-free solder paste and tuner technology, used in welding media, welding/cutting media/materials, metal processing equipment, etc., can solve the problem of poor solderability, large thermal shock damage to components and circuit boards, and easy solder paste. Dropping and other problems, to reduce the damage of thermal shock, strengthen the reliability after welding, and achieve the effect of transparent residue after welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A medium-temperature energy-saving lead-free solder paste for tuners, which is composed of Sn64Bi35Ag1 alloy tin powder and solder paste, and its weight ratio is 10.4% of solder paste and 89.6% of SnBiAg tin powder;

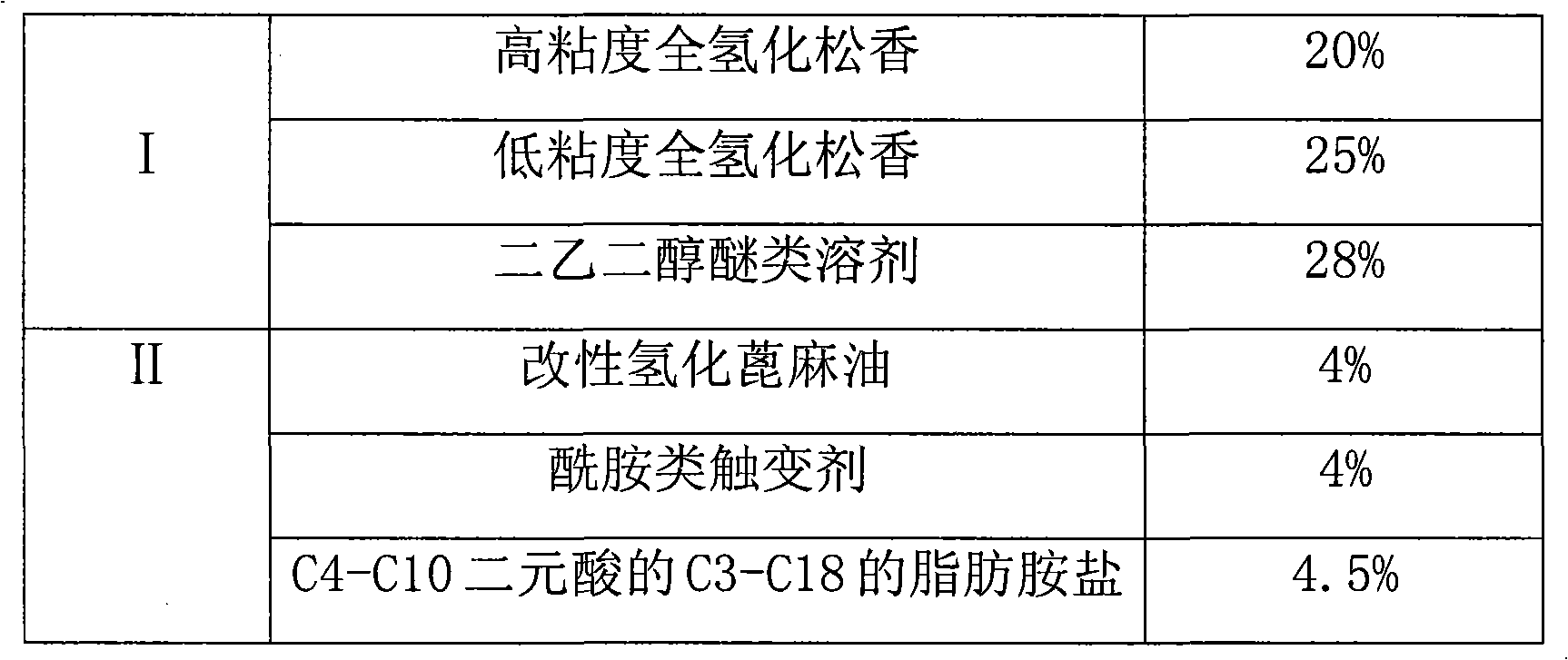

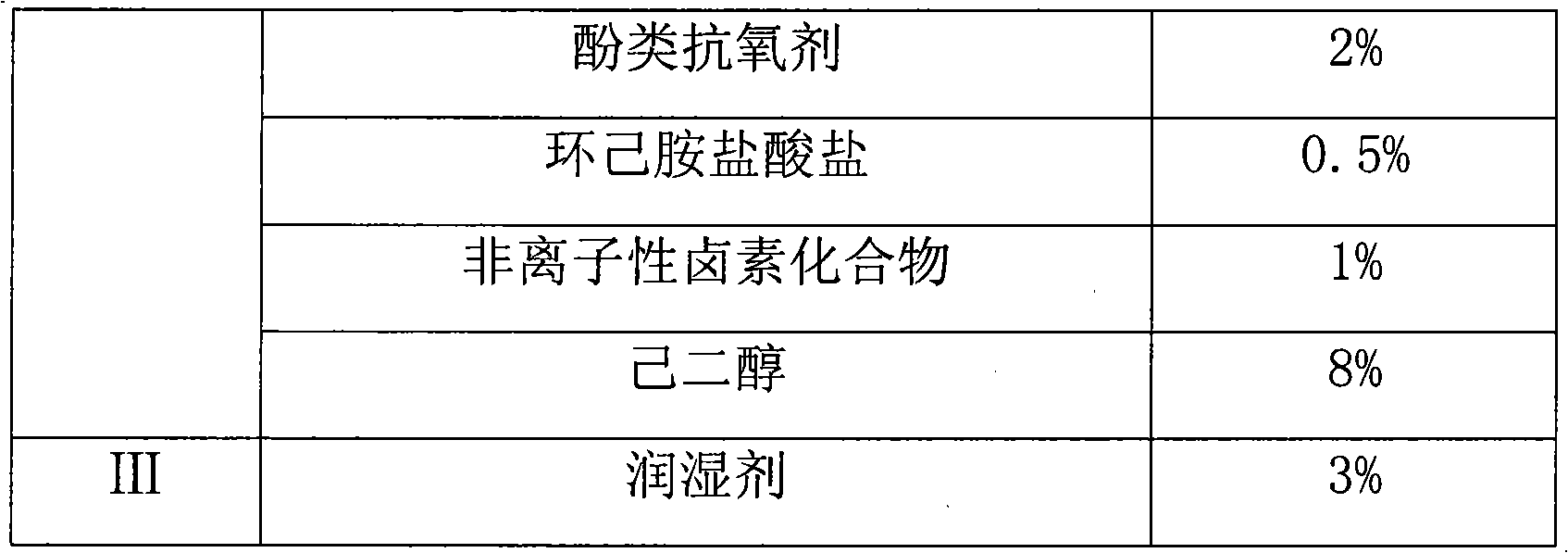

[0014] The solder paste is formulated in the following weight ratios:

[0015]

[0016]

[0017] The solder paste preparation process is:

[0018] ①Put the rosin and solvent in Part I into the reactor, heat at 120°C and keep stirring until it dissolves into a uniform and transparent liquid, then stop heating.

[0019] ② Add the thixotropic agent, active agent, antioxidant and hexanediol in Part II to I, stir continuously until all dissolve into a transparent liquid, cool with cooling water and stir continuously to make it fully react;

[0020] ③Cool and keep stirring to 45°C, add the wetting agent in part III, stir evenly, cool to room temperature, seal the resulting paste in a low temperature environment of 2-8°C and let it stand for 12 hours until...

Embodiment 2

[0025] A medium-temperature energy-saving lead-free solder paste for tuners, which is composed of Sn64Bi35Ag1 alloy tin powder and solder paste, and its weight ratio is 11% of solder paste and 89% of SnBiAg tin powder;

[0026] Soldering paste is prepared according to the following weight ratio:

[0027]

[0028] The preparation method and welding process parameter control are the same as in Example 1.

Embodiment 3

[0030] A medium-temperature energy-saving lead-free solder paste for tuners, which is composed of Sn64Bi35Ag1 alloy tin powder and solder paste, and its weight ratio is 11% of solder paste and 89% of SnBiAg tin powder;

[0031] The solder paste is formulated in the following weight ratios:

[0032]

[0033]

[0034] The preparation method and welding process parameter control are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com