Low-cost wet method underwater welding rods

A low-cost, wet technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of high production quality requirements, low production efficiency, and high production costs, reducing labor intensity and improving production. Efficiency, the effect of stable arc combustion

Inactive Publication Date: 2009-01-21

LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, underwater wet welding materials have been developed successively at home and abroad, but in order to meet the particularity of welding rods in underwater construction, after the production of welding rods, it is necessary to apply a special waterproof layer on the surface, which is not only labor-intensive and production High quality requirements, low production efficiency and high production costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

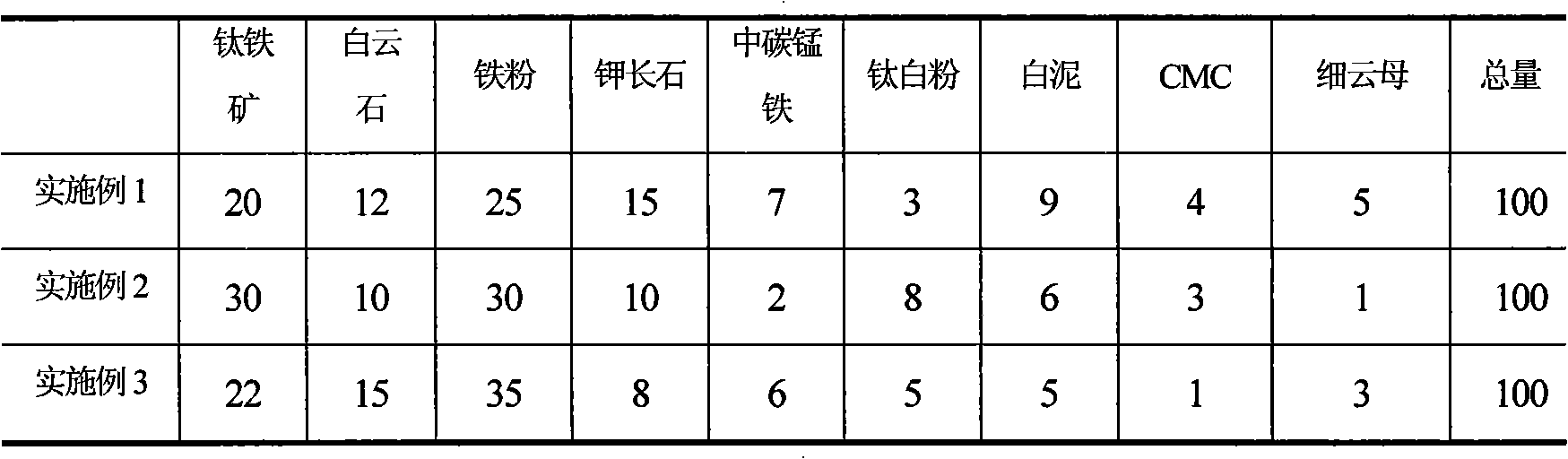

[0018] Example (%)

[0019]

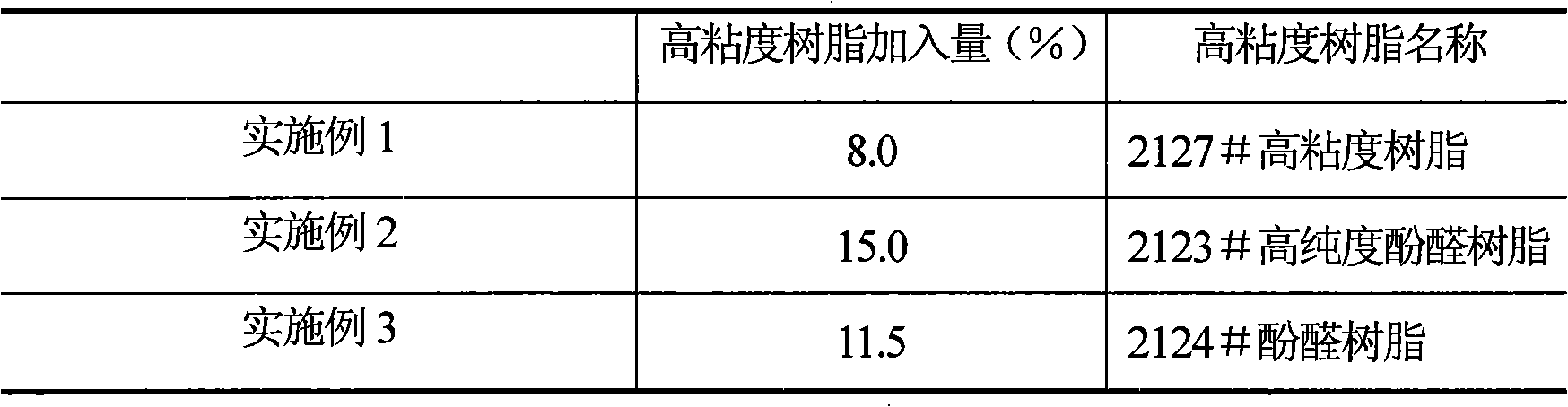

[0020]

[0021] Example effect

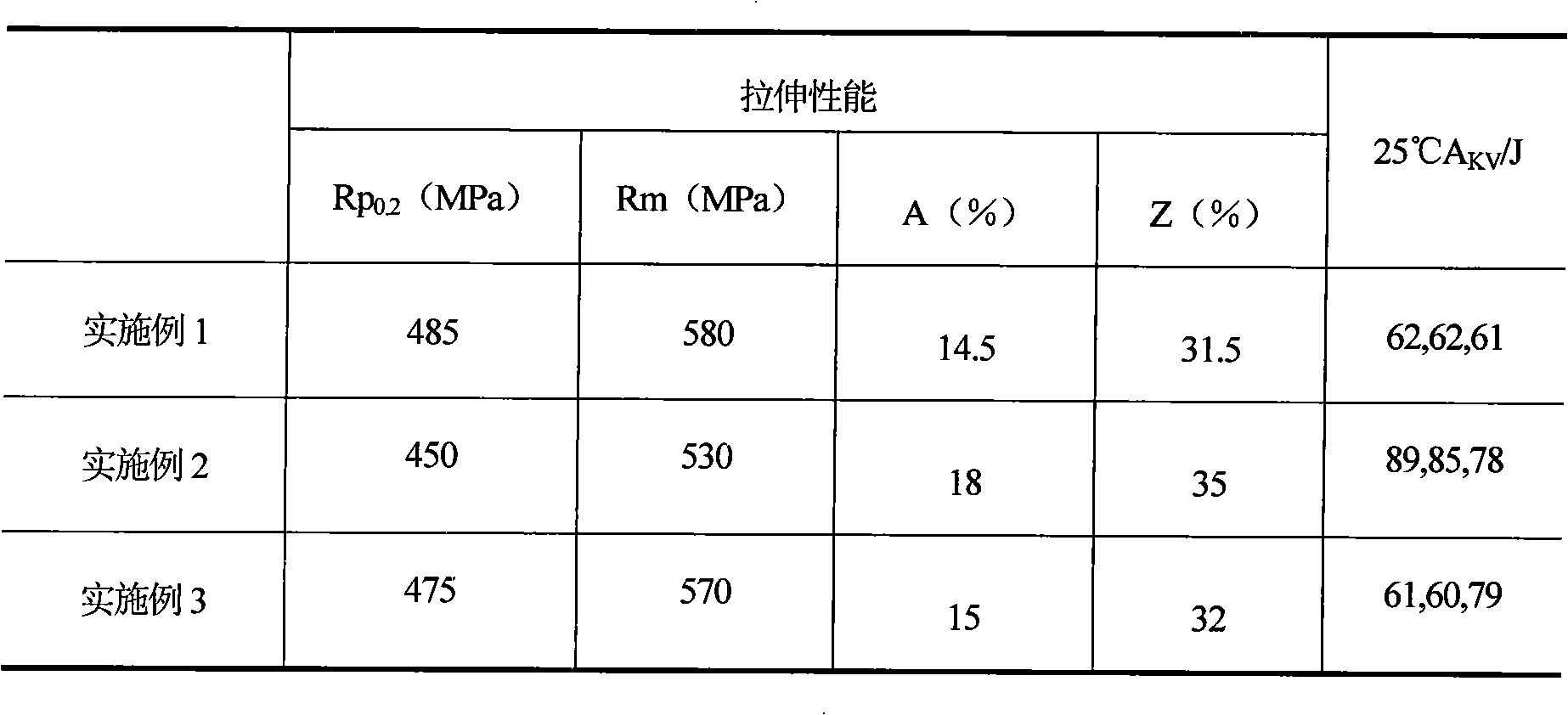

[0022] Deposited Metal Mechanical Properties

[0023]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a low-cost underwater wet welding rod which adopts a commercial H08E welding wire as a welding core; the main components and weight proportion of coating are as follows: 20-30% of ilmenite, 10-15% of dolomite, 25-35% of ferrous powder, 8-15% of potassium feldspar, 2-7% of medium-carbon ferromanganese, 5-9% of white slime, 3-8% of titanium pigment, 1-4% of CMC and 1-5% of fine mica; the high viscosity resin which accounts for 8-15% of the total weight of the coating components is added. By adopting the high viscosity resin as an adhesion agent, the welding rod of the invention can be directly applied to underwater wet welding after extrusion and does not need to be coated with a waterproof coating on the surface, thus simplifying production technique, improving production efficiency and reducing production cost; the invention can ensure that after the welding rod is soaked in water for a long time, the coating dose not go bad and drop off, and welding operation can still be carried out. When used in underwater welding, the welding rod has the advantages of easy arc striking, stable combustion of electric arc, good performance of restarting, easy slag detachability, good weld forming and fine processing property of underwater welding.

Description

technical field [0001] The invention belongs to the field of welding materials and relates to a low-cost underwater wet welding electrode. Background technique [0002] With the advancement of the ocean development process, underwater wet welding electrodes are more and more widely used in military and civilian underwater steel structures such as the construction and maintenance of bridges, port facilities and offshore platforms, and the repair of submarines. At present, underwater wet welding materials have been developed successively at home and abroad, but in order to meet the particularity of welding rods in underwater construction, after the production of welding rods, it is necessary to apply a special waterproof layer on the surface, which is not only labor-intensive and production The quality requirements are high, and the production efficiency is low and the production cost is high. For example, the price of domestic TS208 welding rod is more than 100,000 yuan / ton....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K35/36

Inventor 郭敬杰姚上卫王君民

Owner LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com