Method for assembling and welding ultrathin large-diameter saw blade

A welding method and a technology with large thickness, which can be used in welding equipment, tool manufacturing of sawing machines, arc welding equipment, etc., can solve problems such as easy cracking, and achieve the effects of eliminating welding stress, easy to master the operation process, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

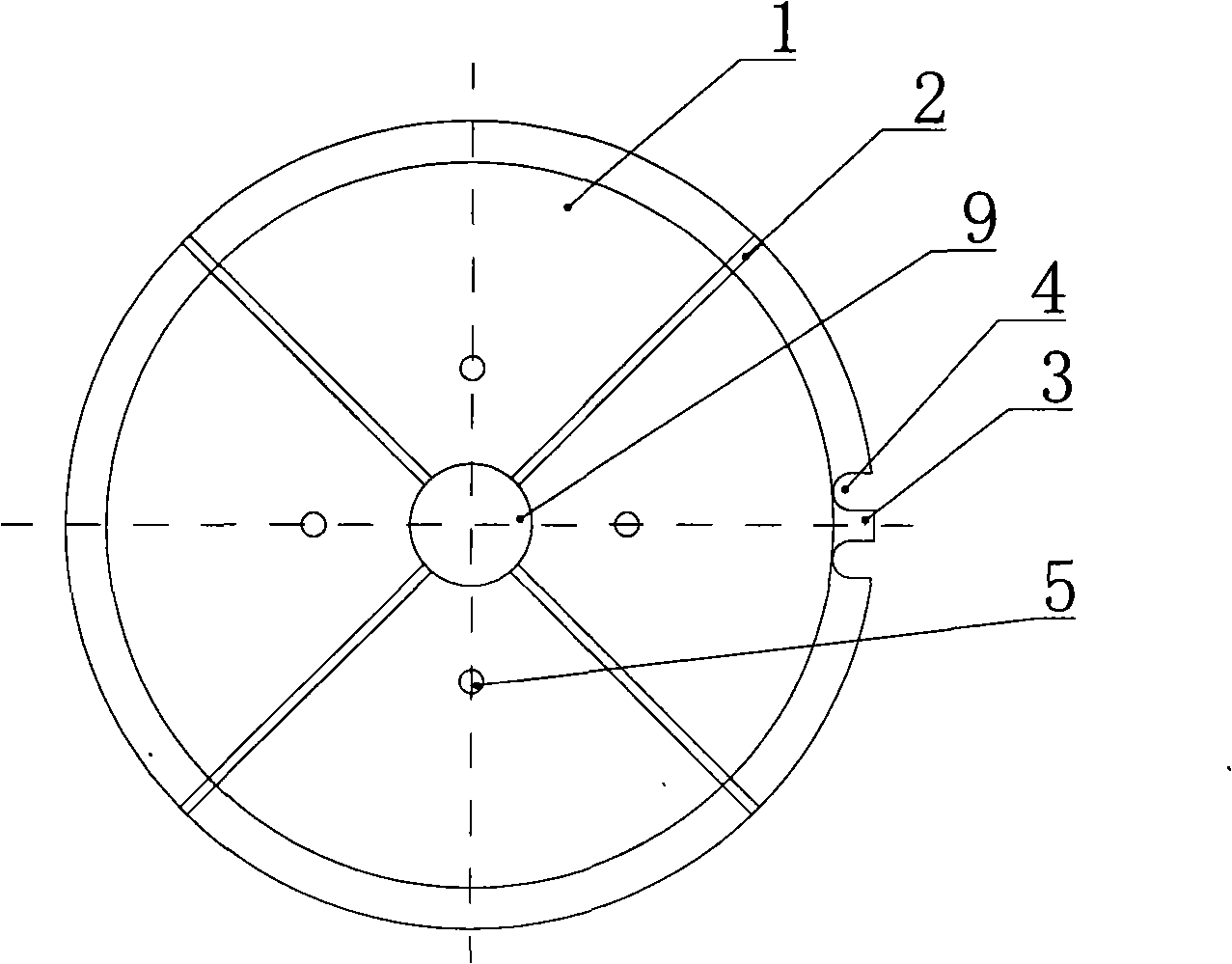

[0023] see figure 1 ~ Fig. 6, the present invention will be further described by taking the assembling and welding of Φ3500mm large-diameter diamond matrix saw blade products as an example.

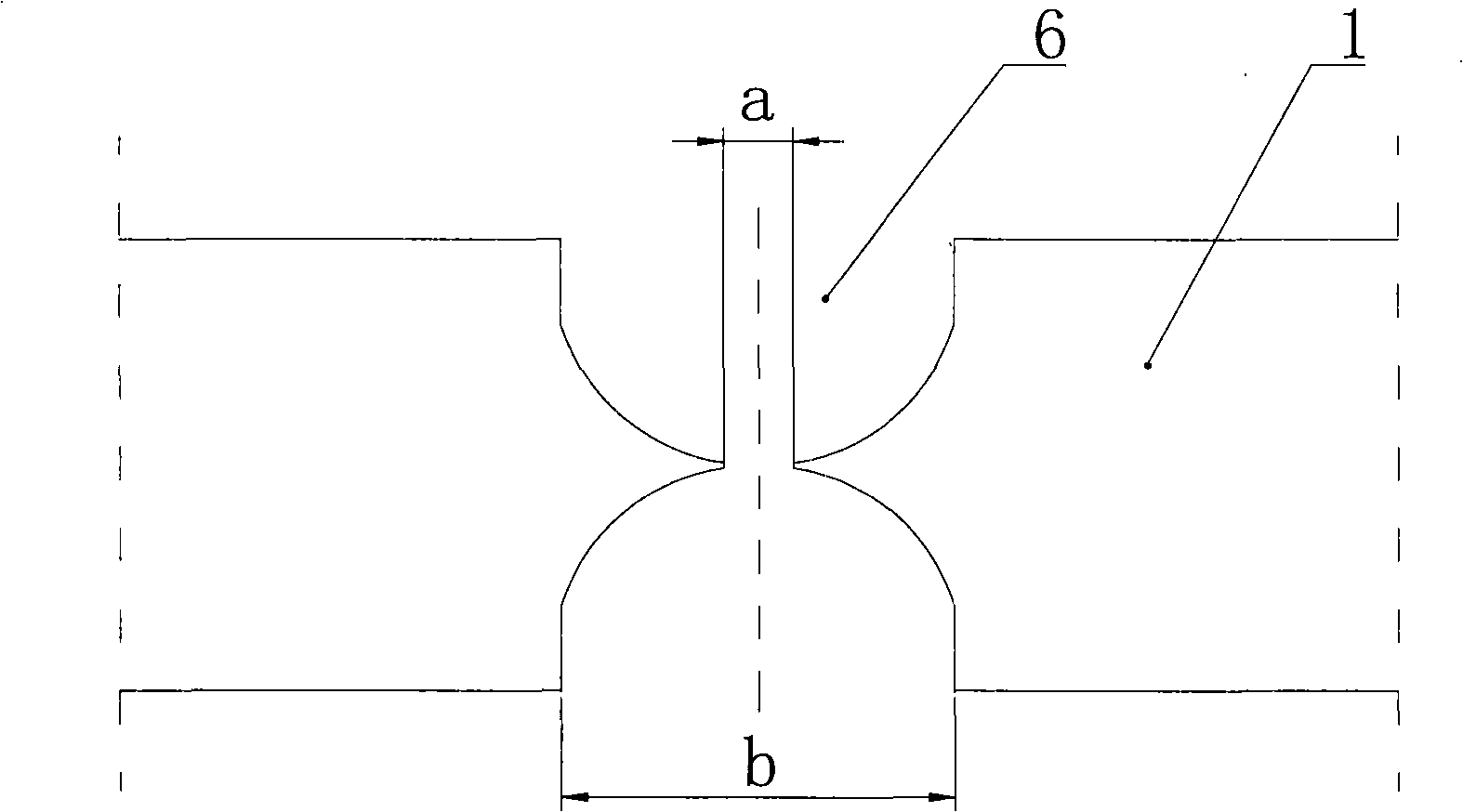

[0024] The material of saw blade 1 is 45Mn2V, normalized state before welding, diameter 3482mm, thickness before welding 13 ±0.2 mm. With laser cutting equipment, the steel plate is pressed figure 1 The design structure shown is cut into four fan-shaped raw materials of the same size, and the center hole 9, the process hole 5, the water tank 4, the sawtooth 3, and the welding groove 6 are processed at the same time. The welding groove 6 on one side is in the form of a U shape. , the mouth width b is 8mm, and the reserved gap a of the weld seam is 2mm, such as figure 2 shown. The design of the symmetrical weld seam of the cross stitching structure can effectively distribute the welding stress evenly. The design of double U-shaped welding groove 6 can realize small-section welds, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com