Method for preparing porous iron-doped titanic oxide photocatalyst

A technology of titanium dioxide and photocatalyst, which is applied in the preparation field of photocatalyst technology, can solve the problems of expensive surfactants, reduced catalytic activity, low photocatalytic activity, etc., and achieves less harsh reaction conditions, less solvent pollution, and simple and direct method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 0.006 g of solid iron trichloride hexahydrate FeCl successively to 50 ml of ethylene glycol solvent 3 ·6H 2 O and 5ml of butyl titanate Ti(OC4 h 9 ) 4 , after stirring for 30 minutes, the solution was transferred to a round-bottomed flask, refluxed at 180 ° C for 3 hours, and then naturally cooled to room temperature;

[0037] Use a centrifuge to separate the above solution, and then repeatedly wash with absolute ethanol 3 times to obtain a metal alkoxide solid, and the molar percentage of iron in the metal alkoxide solid is equal to 0.25%;

[0038] Dry the obtained metal alkoxide solid at 50°C for 6 hours to obtain the heteronuclear metal alkoxide Fe x Ti 1-x (OCH 2 CH 2 O) 2 Precursor solid powder, wherein x=0.25%;

[0039] In a muffle furnace, the synthesized heteronuclear metal alkoxide is heated at 400° C. for 2 hours to obtain a solid powder of porous iron-doped titanium dioxide photocatalyst with an iron doping amount equal to 0.25%.

[0040] Some st...

Embodiment 2

[0042] Add 0.012g of solid iron trichloride hexahydrate FeCl successively to 50ml of ethylene glycol solvent 3 ·6H 2 O and 5ml of butyl titanate Ti(OC 4 h 9 ) 4 , after stirring for 30 minutes, the solution was transferred to a round-bottomed flask, refluxed at 180°C for 5 hours, and then naturally cooled to room temperature;

[0043] Use a centrifuge to separate the above solution, and then repeatedly wash with absolute ethanol 3 times to obtain a metal alkoxide solid, and the molar percentage of iron in the metal alkoxide solid is 0.5%;

[0044] Dry the obtained metal alkoxide solid at 50°C for 6 hours to obtain the heteronuclear metal alkoxide Fe x Ti 1-x (OCH 2 CH 2 O) 2 Precursor solid powder, where x=0.5%;

[0045] In a muffle furnace, the synthesized heteronuclear metal alkoxide is heated at 400° C. for 2 hours to obtain a solid powder of a porous iron-doped titanium dioxide photocatalyst with an iron doping amount equal to 0.50%.

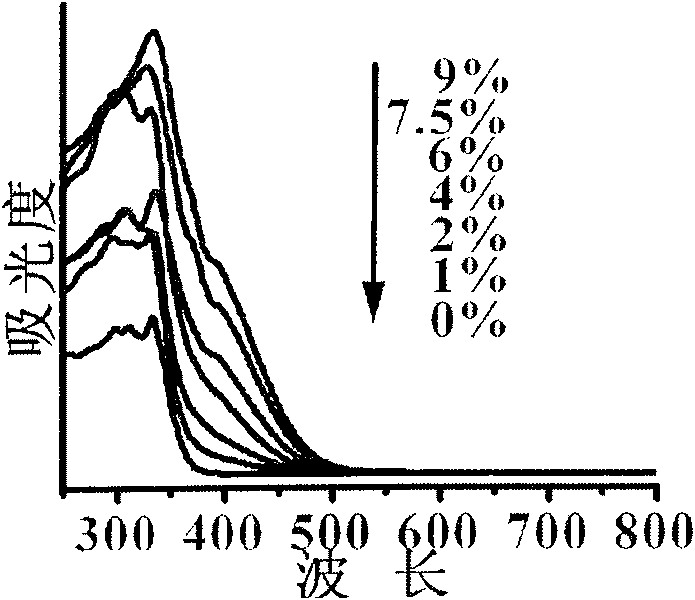

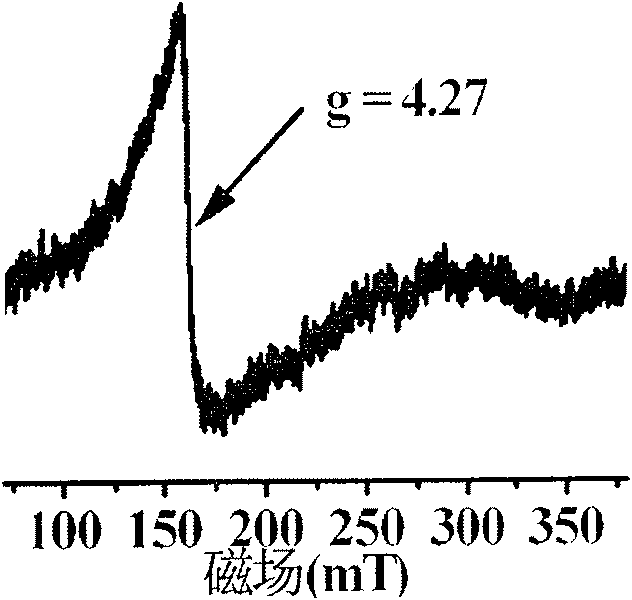

[0046] Such as Figure 6 T...

Embodiment 3

[0051] Add 0.006 g of solid iron trichloride hexahydrate FeCl successively to 50 ml of ethylene glycol solvent 3 ·6H 2 O and 5ml of butyl titanate Ti(OC 4 h 9 ) 4 , after stirring for 30 minutes, the solution was transferred to a round-bottomed flask, refluxed at 180 ° C for 3 hours, and then naturally cooled to room temperature;

[0052] Use a centrifuge to separate the above solution, and then repeatedly wash with absolute ethanol 3 times to obtain a metal alkoxide solid, and the molar percentage of iron in the metal alkoxide solid is 0.25%;

[0053] Dry the obtained metal alkoxide solid at 50°C for 6 hours to obtain the heteronuclear metal alkoxide Fe x Ti 1-x (OCH 2 CH 2 O) 2 Precursor solid powder, wherein x=0.25%;

[0054] Divide the synthesized heteronuclear metal alkoxide into five equal parts, and heat in a muffle furnace at 350°C for two hours, 400°C for two hours, 450°C for two hours, 500°C for two hours, and 550°C for 2 hours to obtain five A solid powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com