Catalyst for eliminating chlorinated aromatic hydrocarbons by low-temperature catalytic combustion

A technology of chlorinated aromatic hydrocarbons and low-temperature catalysis, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, combustion methods, etc., can solve the problem of easy loss of catalyst active components and low catalytic combustion activity , short catalyst life and other problems, to achieve the effect of convenient and practical technical route, high catalytic activity and strong resistance to chlorine poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Commercially available 4.1g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), 4.3g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 680.4g aluminum nitrate (Al(NO 3 ) 3 ·6H 2 O) into 40.9g manganese nitrate (Mn(NO 3 ) 2 ) 50wt% aqueous solution, add deionized water to make the volume of the solution reach 350ml, dissolve at room temperature, add 100g citric acid, and make it dissolve. Place the solution in a constant temperature water bath at 80°C and stir for 6-7 hours; then put it in a drying oven at 110°C for 12 hours, move it to a roasting furnace, and program the temperature in the air atmosphere, 4.2°C per minute, rising to 550°C, Keep warm for 5 hours to get 17.6% Mn 2 o 3 -1.2% CeO 2 -1.2% La 2 o 3 -80%Al 2 o 3 catalyst. Tablet crushing 20-40 mesh particles, ready to use.

[0025] Prepare 16% Fe by implementing the method of 1 2 o 3 -2%CeO 2 -2% La 2 o 3 -80%Al 2 o 3 The catalyst is Example 2.

[0026] Prepare 16% Mn by implementing the method of 1 2 o 3...

Embodiment 6

[0030] Commercially available 8.2g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), 680.4g aluminum nitrate (Al(NO 3 ) 3 ·6H 2 O) into 40.9g manganese nitrate (Mn(NO 3 ) 2 ) 50wt% aqueous solution, add deionized water to make the volume of the solution reach 350ml, dissolve at room temperature, add 100g citric acid, and make it dissolve. Place the solution in a constant temperature water bath at 80°C and stir for 6-7 hours; then put it in a drying oven at 110°C for 12 hours, move it to a roasting furnace, and program the temperature in the air atmosphere, 4.2°C per minute, rising to 550°C, Keep warm for 5 hours to get 17.6% Mn 2 o 3 -2.4% CeO 2 -80%Al 2 o 3 catalyst.

[0031] Prepare 16%NiO-4%CeO with the method of implementation 6 2 -80%Al 2 o 3 The catalyst is Example 7.

[0032] Prepare 16% Co by implementing the method of 6 2 o 3 -4%CeO 2 -80%Al 2 o 3 The catalyst is Example 8.

Embodiment 9

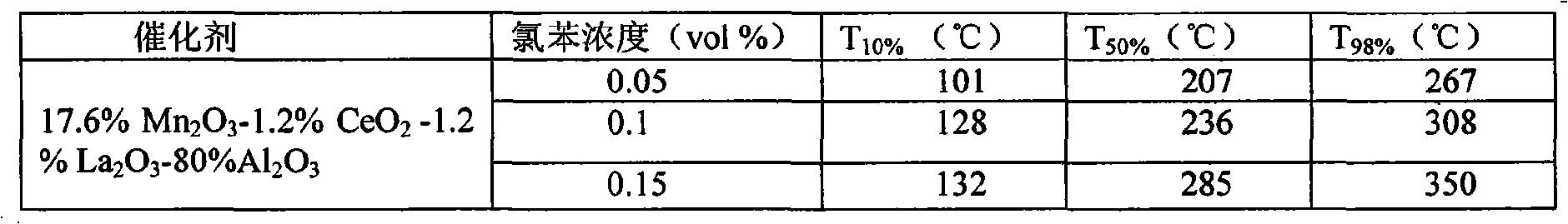

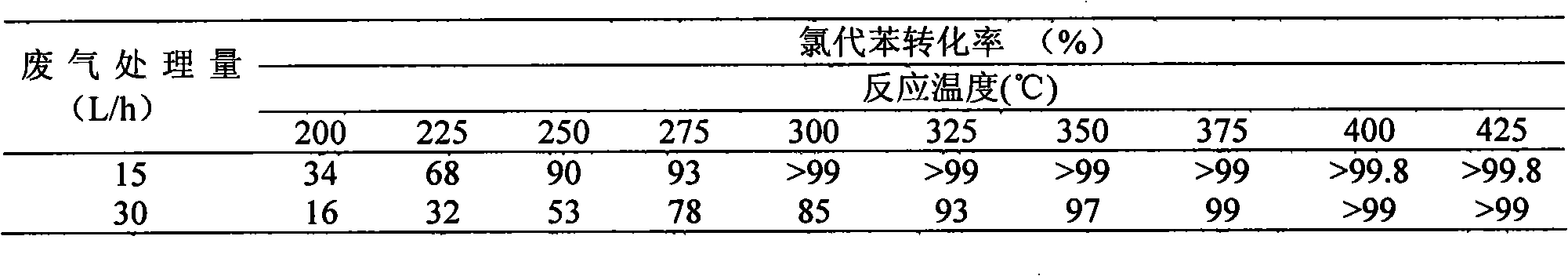

[0034] Catalyst activity evaluation was carried out in a fixed bed reactor. The chlorobenzene combustion activity tests of all catalysts were carried out in a U-shaped quartz micro-reactor (inner diameter 6 mm), the amount of catalyst was 200 mg, and the temperature was automatically controlled by a K-type thermocouple. Chlorobenzene is injected into the vaporization chamber by the 100 series KDS120 micro-injection pump of Stoelting Company in the United States, and then mixed with air and then enters the reactor for combustion. The total flow is controlled by a mass flow meter, the concentration of chlorobenzene is controlled at 0.1vol%, the amount of exhaust gas treated per gram of catalyst per hour is 15L, and the linear velocity of gas passing through the reactor is 120m / h. Reaction pressure is 0.1Mpa, and the relation of the conversion ratio of chlorobenzene and reaction temperature is shown in Table 1, and T in Table 1 10% , T 50% , T 98% are the reaction temperatures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com