Barometric pressure microwave plasma generation device

A technology of microwave plasma and generating device is applied in the field of plasma to achieve the effects of enhancing cooling effect, avoiding erosion and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

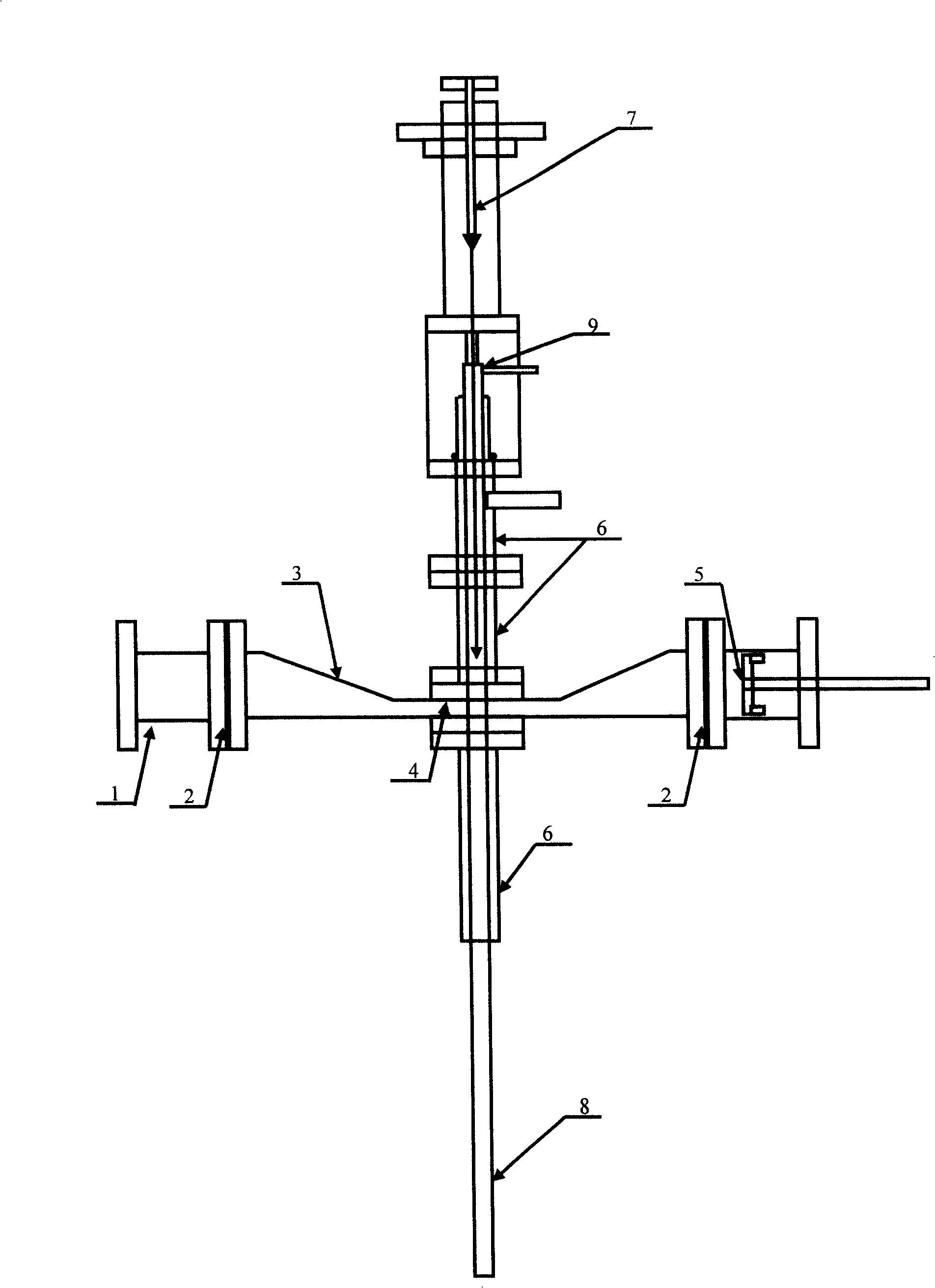

[0011] Such as figure 1 As shown, the generating device consists of a rectangular waveguide 1, a wave-transparent gas sealing film 2, a waveguide conversion mechanism 3, a microwave resonator 4, an adjustable phase matcher 5 at the cut-off end, a reactor 6, an igniter 7, and an outer cooling jacket The pipe 8 and the rotating air flow generating part 9 are composed. The rectangular waveguide 1 is connected to the microwave generator, and the size design generally meets the following requirements: λ<a<2λ, λ / 2<b<λ, where a is the length of the broad side of the rectangular waveguide 1, and b is the rectangular waveguide 1 is the length of the narrow side, and λ is the transmitted microwave wavelength. The microwave passes through the wave-transparent gas sealing film 2 through the rectangular waveguide 1 and enters the waveguide conversion mechanism 3. The waveguide conversion mechanism 3 gradually shrinks the narrow side of the rectangular waveguide 1, and injects the microwav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com