Method for forming graphic pattern

A patterning and patterning technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of inability to achieve line width, increase process costs, etc., and achieve the effect of increasing integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

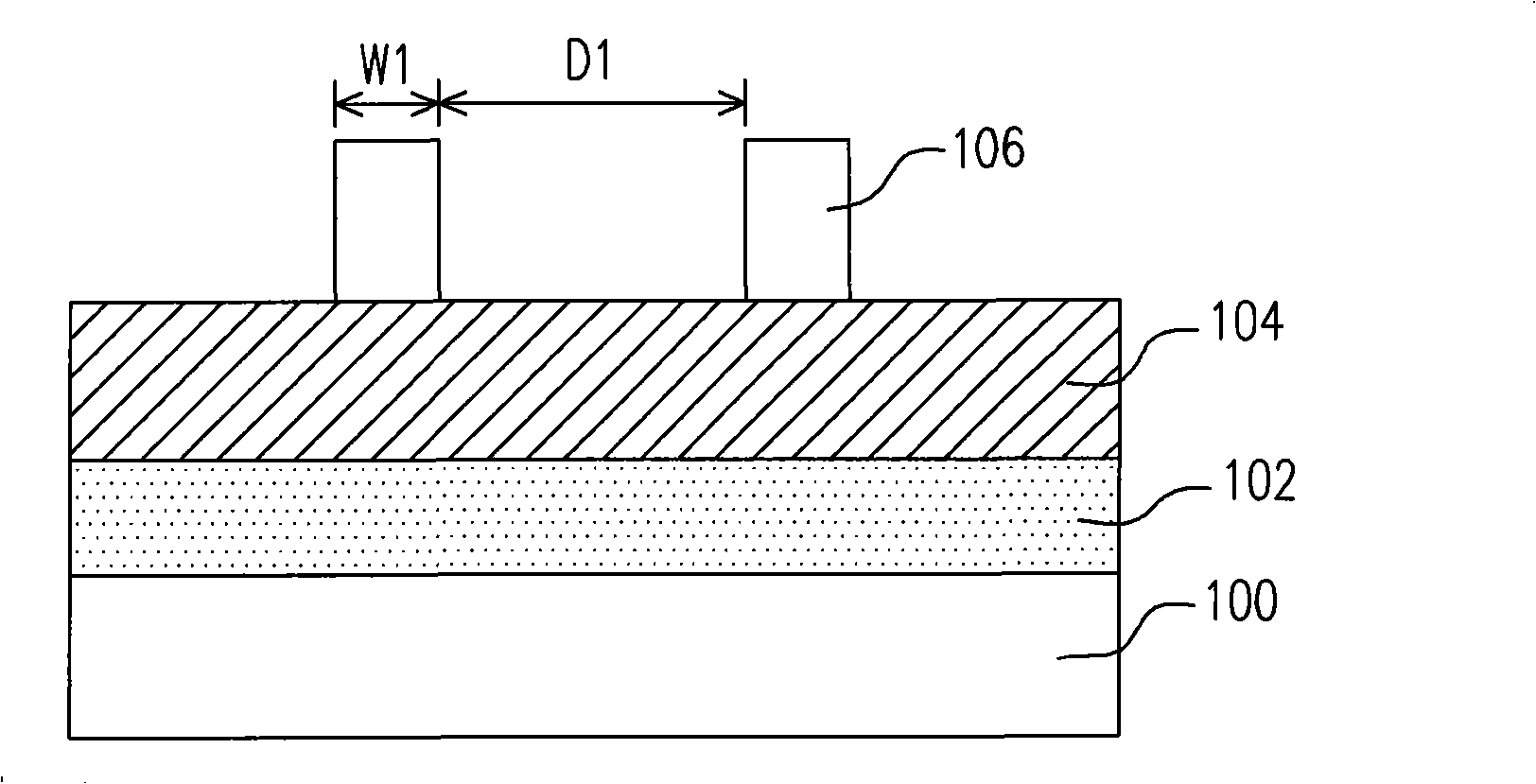

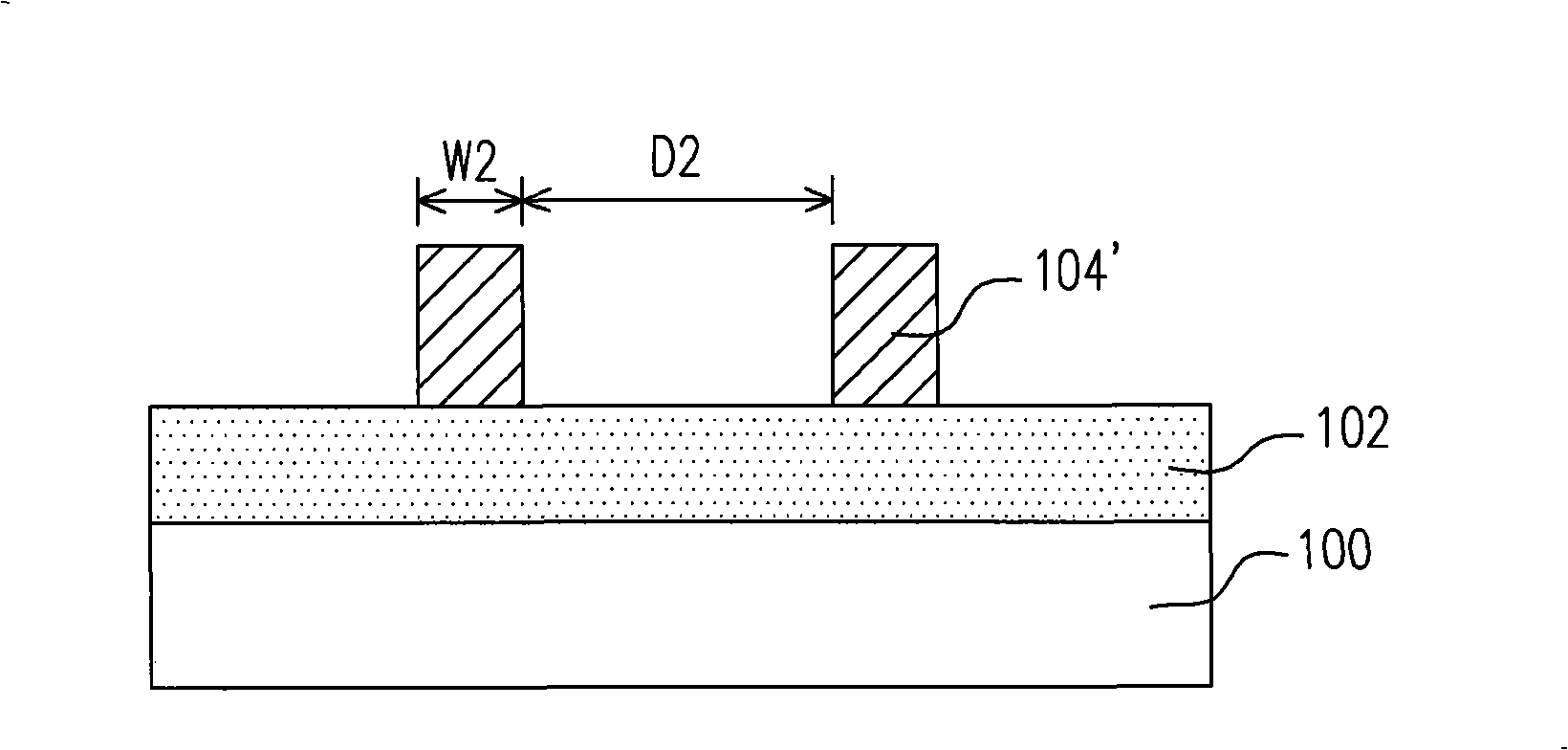

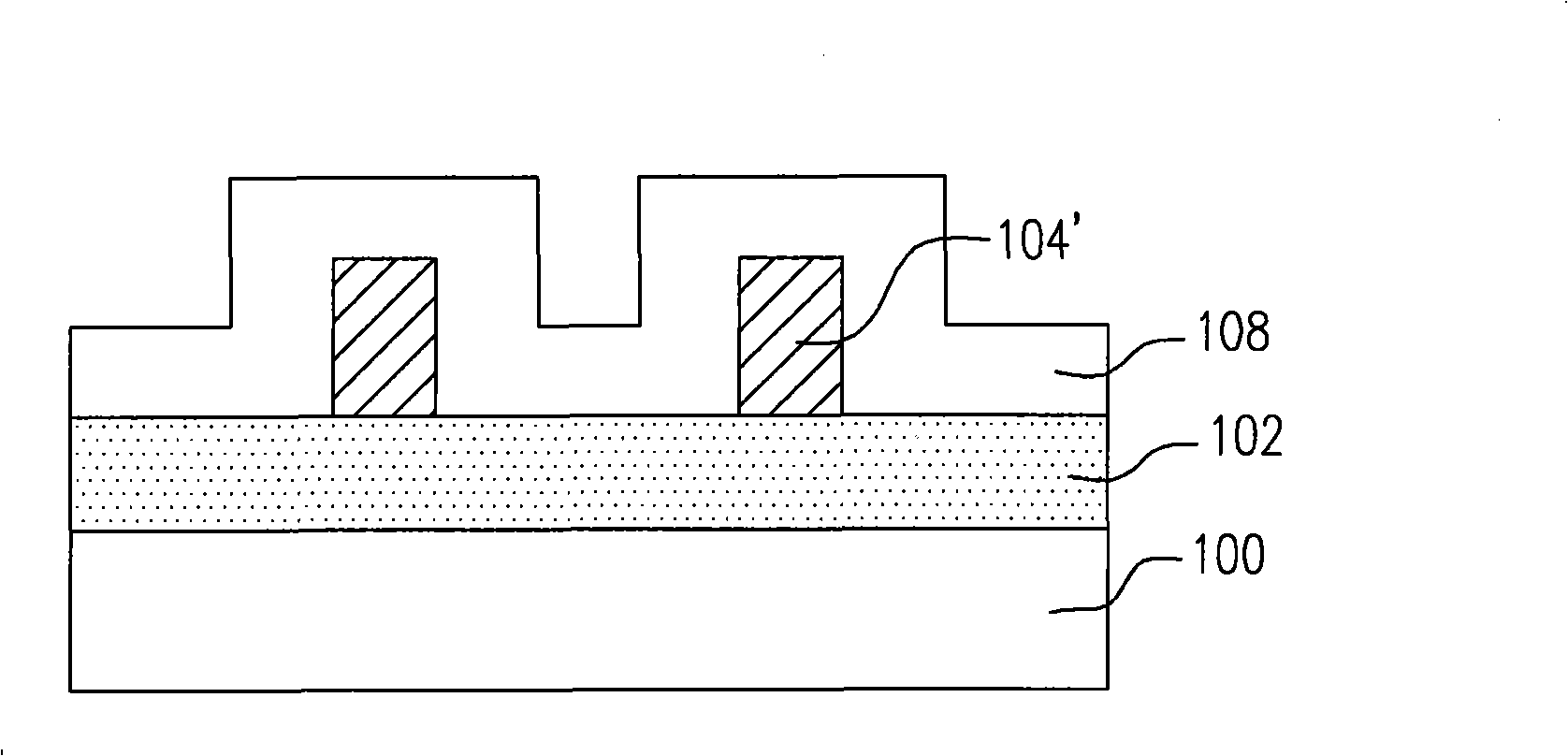

[0025] 1A to 1G It is a cross-sectional view of a manufacturing process of a pattern according to an embodiment of the present invention.

[0026] First, please refer to Figure 1A , a material layer 100 is provided. The material layer 100 is, for example, a polysilicon layer, a dielectric layer or a metal layer. The formation method of the material layer 100 is, for example, a physical vapor deposition process or a chemical vapor deposition process, which can be adjusted according to different material requirements. After that, a mask layer 102 is formed on the material layer 100 . The material of the mask layer 102 is, for example, nitride or oxide. The formation method of the mask layer 102 is, for example, a chemical vapor deposition process. Subsequently, a hard mask layer 104 is formed on the mask layer 102 . The material of the hard mask layer 104 is, for example, nitride or oxide. The formation method of the hard mask layer 104 is, for example, a chemical vapor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com