Refrigeration and microwave irradiation integrated microwave chemical reaction apparatus

A microwave irradiation and chemical reaction technology, applied in the field of microwave chemical reaction devices, can solve the problems of high cost of reaction conditions, no essential changes, inability to quantify and reproduce, etc., to increase heat-sensitive side reactions and eliminate heat-sensitive Side reactions, the effect of raising the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The device of the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

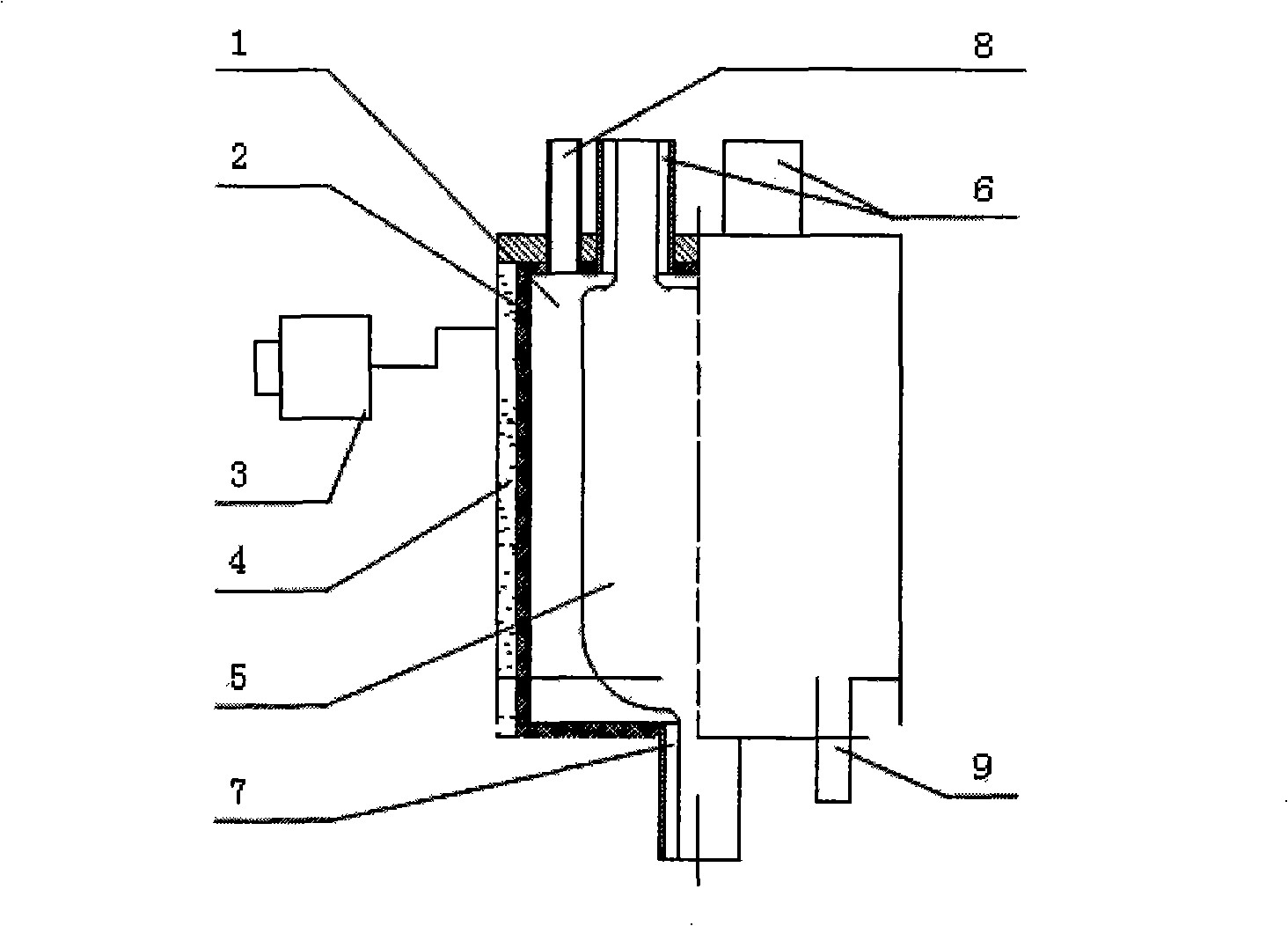

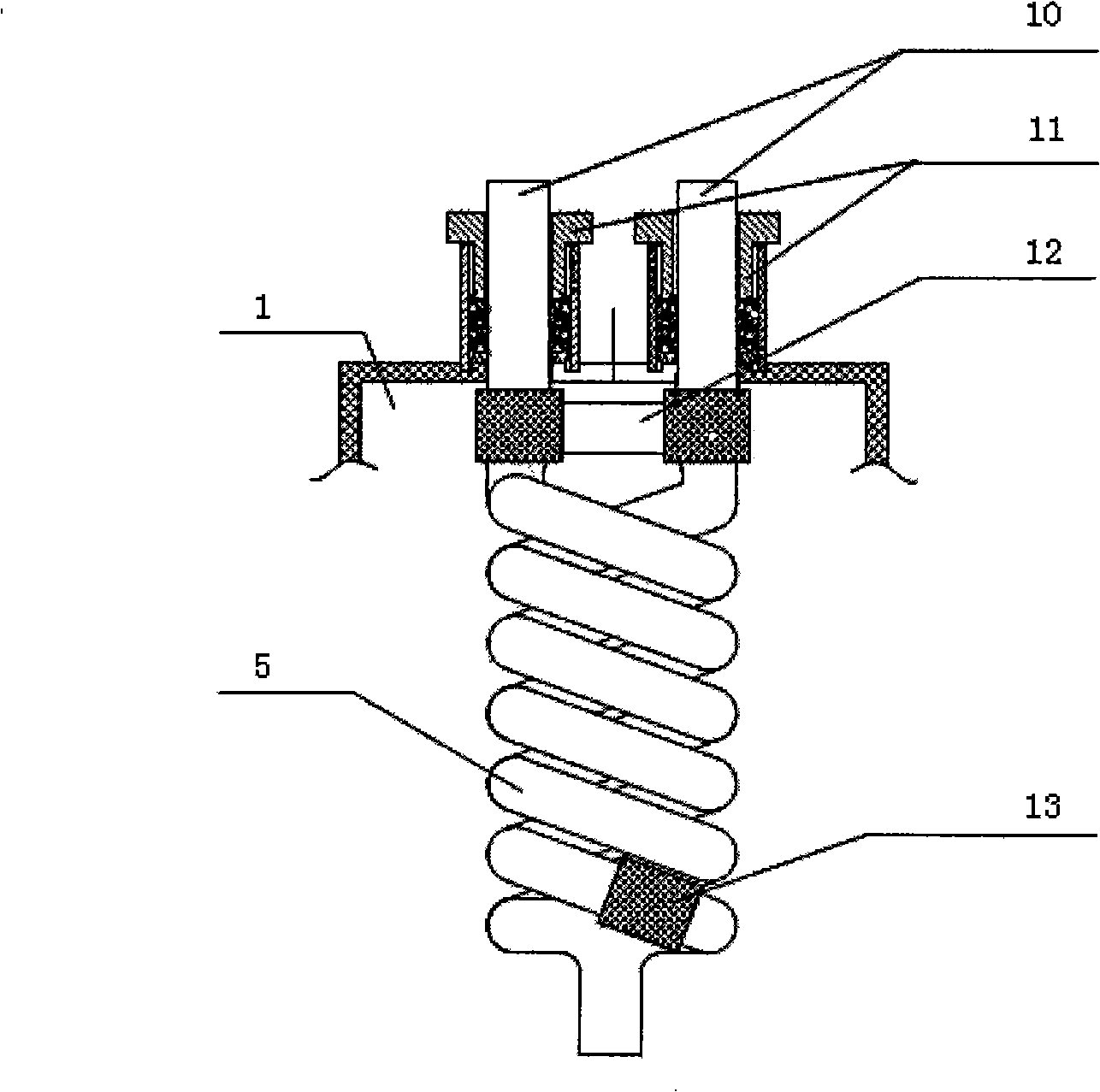

[0055] Such as figure 1 Shown is a system block diagram of the present invention. The present invention may include a microwave irradiation cavity and an embedded microwave reaction container installed in the microwave irradiation cavity, and the microwave frequency provided by the microwave irradiation cavity is 915MHz or 2450MHz. Microwave power supply and magnetron, refrigeration device, temperature feedback system and control system, the microwave irradiation chamber is directly connected to the refrigeration device that can continuously cool the microwave irradiation chamber, and the circulating refrigerant is continuously provided by the refrigerant circulation device and the refrigeration device. Filling the entire microwave irradiation chamber, the reaction vessel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com