Method, apparatus and system for biodiesel production from algae

A device and algae technology, applied in biochemical equipment and methods, biological material sampling methods, botanical equipment and methods, etc., can solve problems such as low oil prices, difficult competition, and limited commercialization potential of algae cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Example 1. Bioreactor system

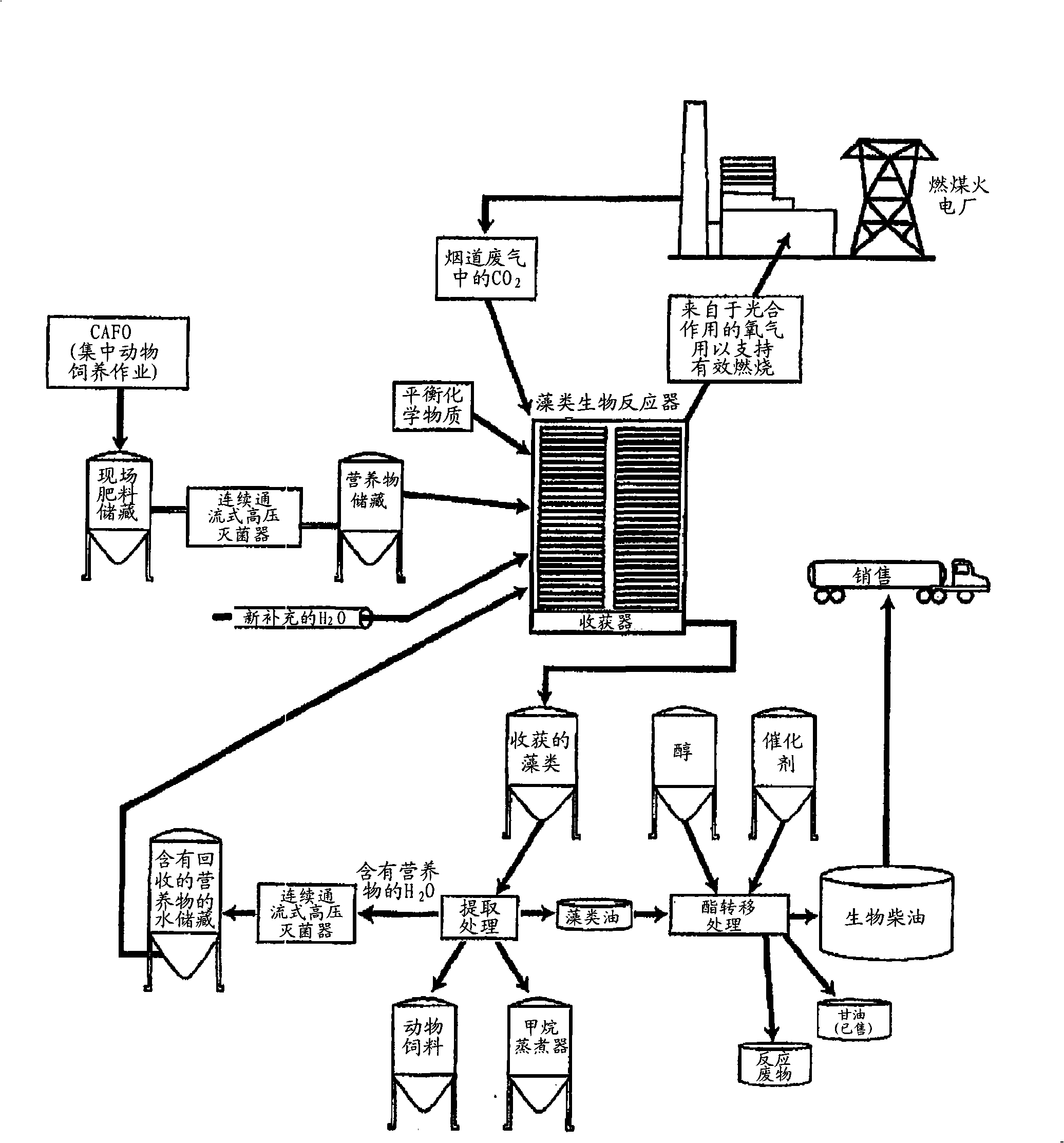

[0068] figure 1 A schematic of an exemplary system is depicted. Elements of this exemplary system include bioreaction technology, harvesting technology, sterilization technology, CO 2 Injection technology, extraction technology, remote-driven bioreactor technology. Such as figure 1 As described, algae farming operations can obtain nutrients from animal feeding operations, such as swine manure. After treatment and sterilization, such organic nutrients can be preserved and / or added to the culture medium to support algae growth. As photosynthetic algae "fix" CO 2 to convert to organic carbon compounds, CO 2 Sources such as power plant exhaust can be utilized to convert dissolved CO 2 added to the medium. CO 2 And nutrients can be utilized by algae to make oil and other biological products. The algae are harvested and oils, proteins, greases, sugars and other components can be extracted. Organic components not used in biodiesel manufactur...

Embodiment 2

Embodiment 2. bioreactor cultivation

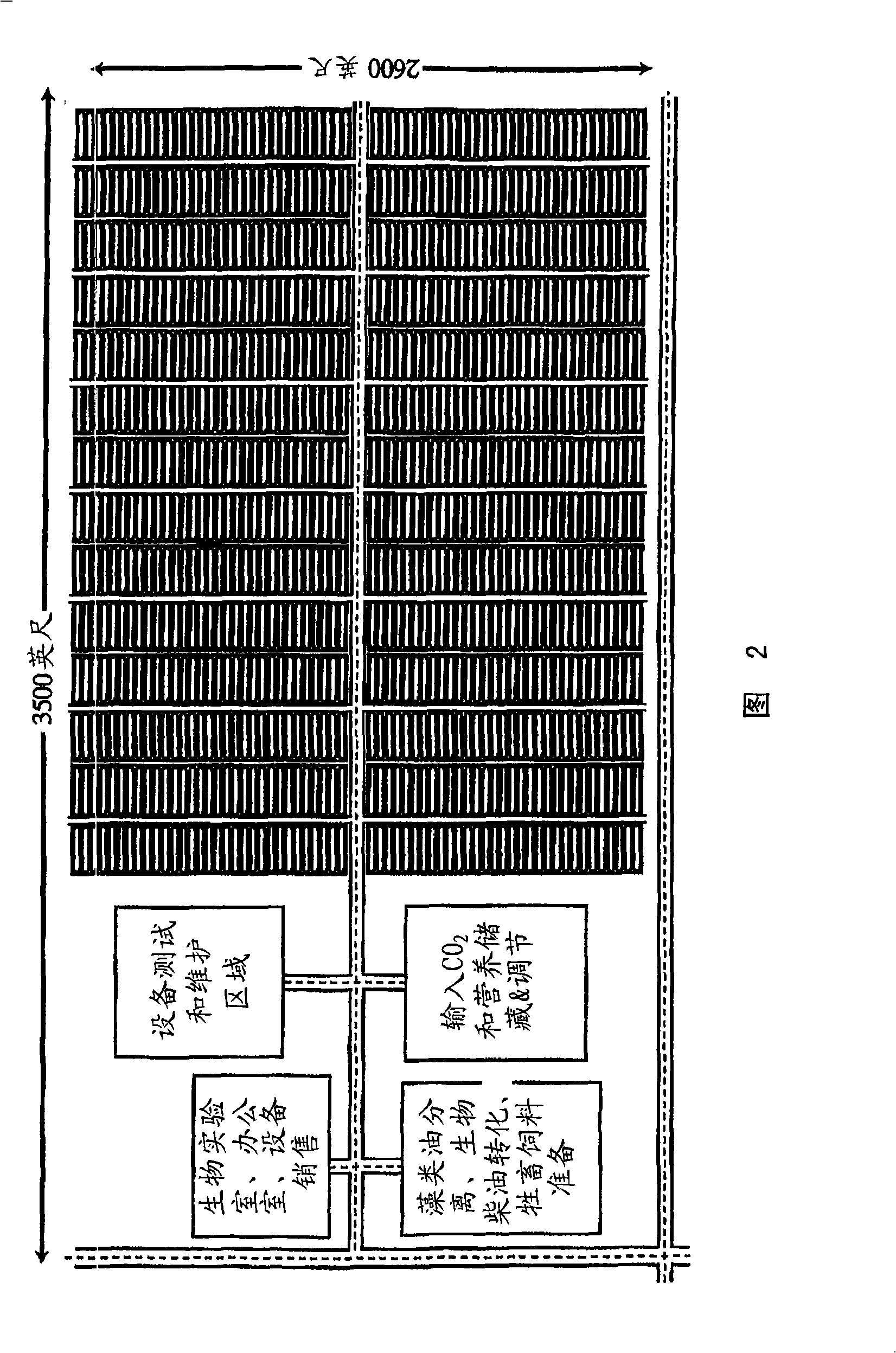

[0070]Certain exemplary embodiments are depicted in Figure 2, which shows an aerial view of a closed bioreactor system for algae cultivation. In this exemplary depiction, algae crops are grown in substantially horizontal clear plastic tubes lying flat on the ground through which sufficient growth medium flows to keep the algae in suspension. (Basic level means that the slope of the ground surface under a single bioreactor is within approximately 1 inch of horizontal, so effects such as mixing, water flow, and plastic pipe pressure are generally constant throughout the pipe. However, skilled artisans will recognize In other embodiments, a terraced approach can also be employed to achieve large arrays of independent bioreactors, where fluid is pumped from lower to upper parts of the overall system). In a preferred embodiment, the pipe is thin walled for economy and is constrained by the side walls to spread over the ground until it is fille...

Embodiment 3

Example 3. Closed system bioreactor setup

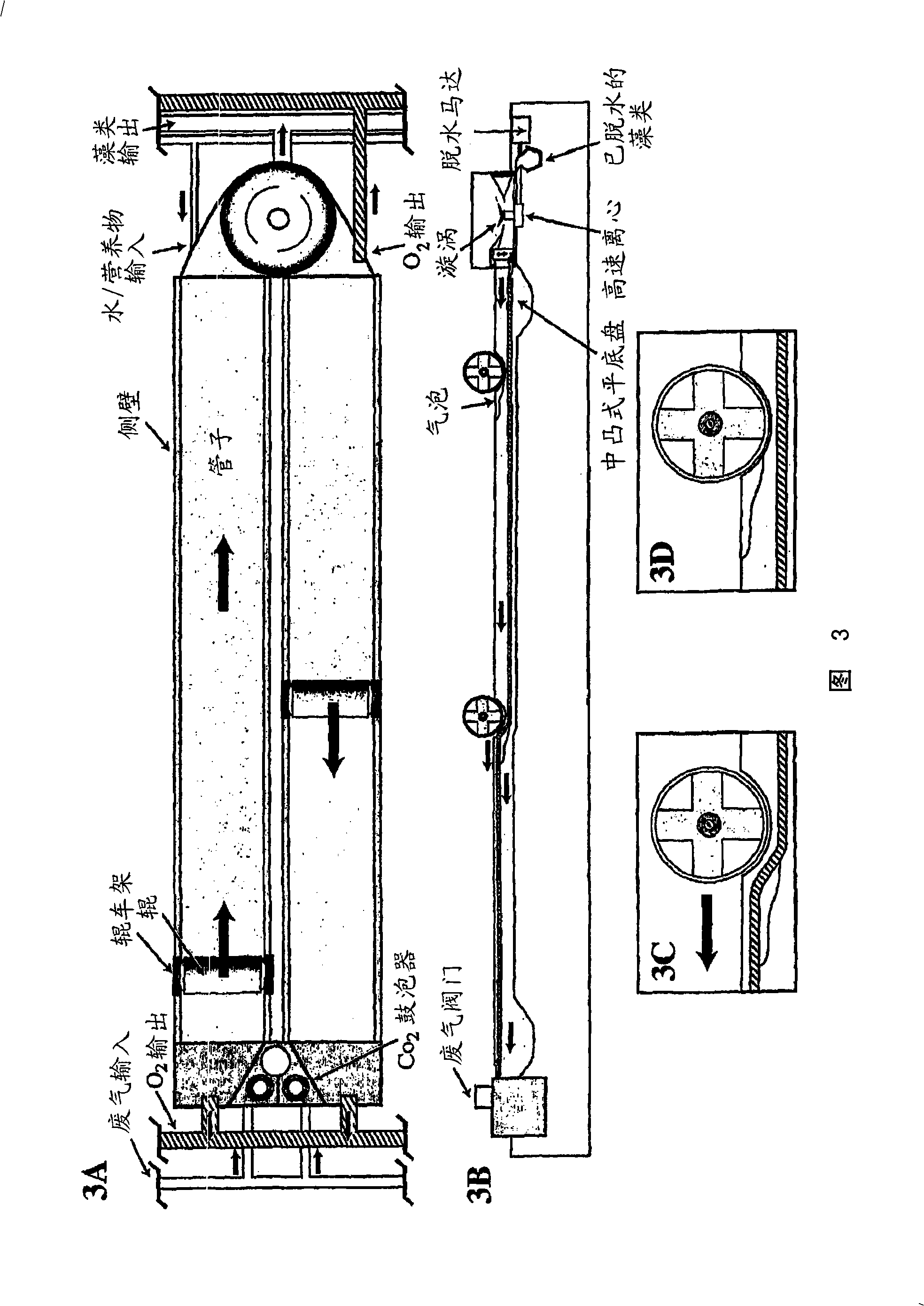

[0072] Figures 3A-D show a non-limiting example of a closed system bioreactor setup. The aqueous culture medium is contained in a substantially transparent tube (bag), discussed in more detail below. The liquid contents of the bag are circulated by movable rollers that roll across the face of the bag pushing the liquid in front of it. In this non-limiting example, the rollers travel along a roller support track and are pulled by cables connected to a carriage that rolls on top of the track. The roller drive system depicted in Figure 25 provides the driving force for the movement of the rollers. In an alternative embodiment not shown here, when the rollers reach the end of the bag, they may rotate or lift upwards, following a continuous elliptical path back to the starting point. However, in the preferred embodiment shown, two-way rollers are employed which travel from one end of the bag to the other and then reverse back to the sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com