Cleaning type gas collecting pipe for thermal recovery coke oven

A heat recovery and gas collecting pipe technology is applied in coke ovens, coke oven heating, dry distillation gas discharge devices, etc. The effect of shortened coking time, low thermal shrinkage, and increased evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

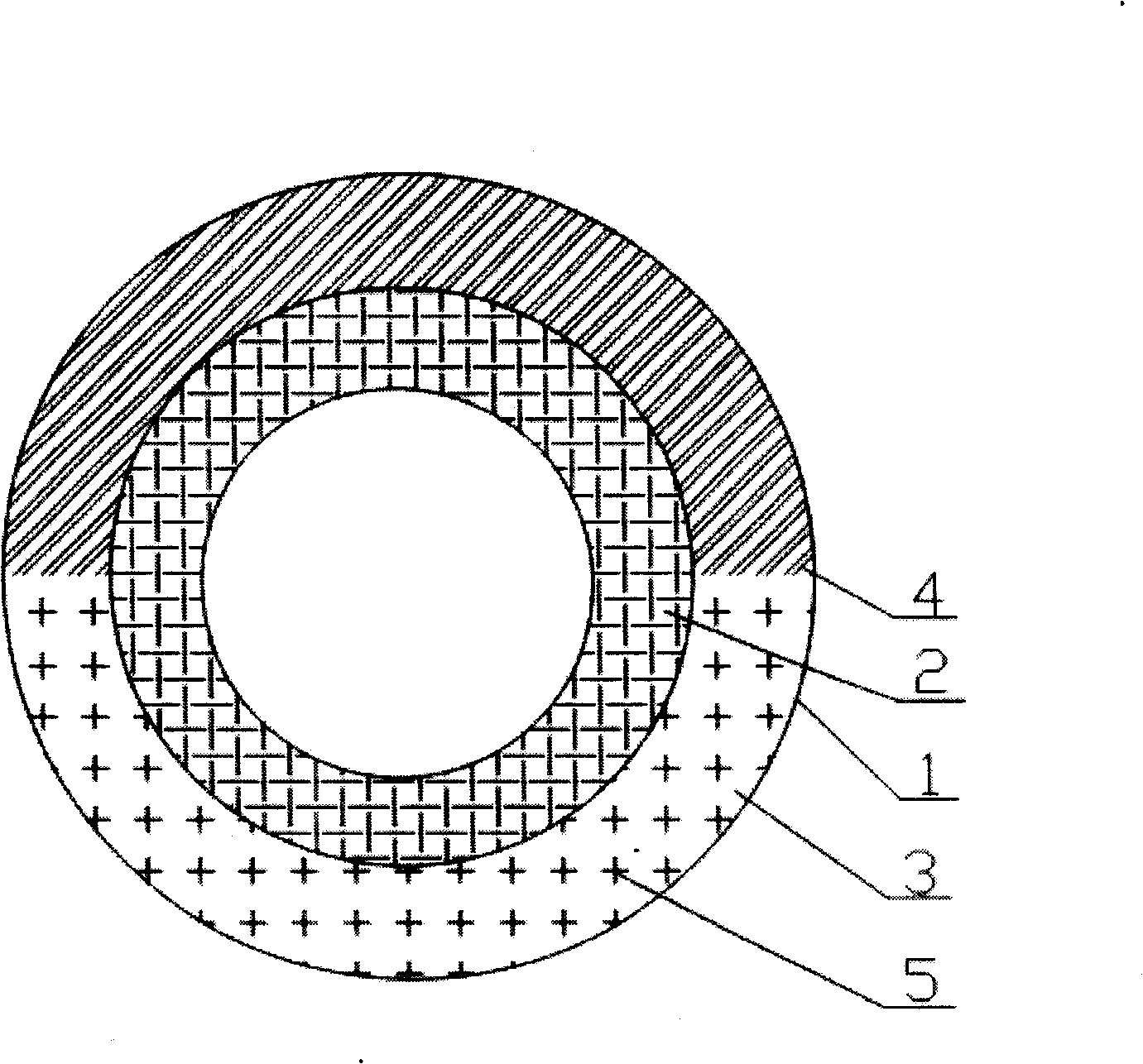

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] As shown in the figure, the air collecting pipe is composed of an outer casing 1 and an inner lining, wherein the inner lining is composed of a primary insulation layer 2 and a secondary insulation layer 3 located between the primary insulation layer 2 and the casing 1, and the primary insulation layer 2 It is made of anti-carburization mullite bricks stacked with high-temperature adhesive. The amount of the above-mentioned high-temperature adhesive is 0.44 kg for each anti-carburization mullite brick. Alumina fiber cotton 4 and its lower part of asbestos-free calcium silicate 5 are bonded and solidified by a high-alumina binder. The amount of the above-mentioned high-alumina binder is 1 kg per square meter of insulating silicate material. . Aluminum silicate fiber cotton or asbestos-free calcium silicate can also be directly selected for the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com