Electric heating steam generator

A steam generator and electric heating technology, applied in steam boilers, electrode boilers, sustainable manufacturing/processing, etc., can solve the problems of rigid station arrangement, energy consumption, and environmental pollution in clothing production sites, and facilitate standardized operations , high heating efficiency, and the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

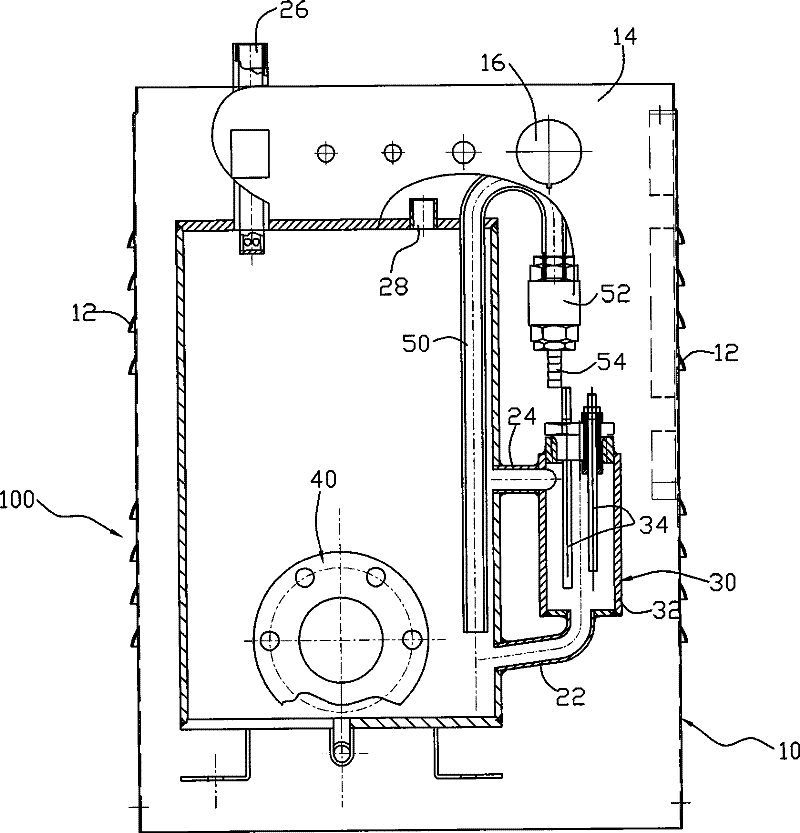

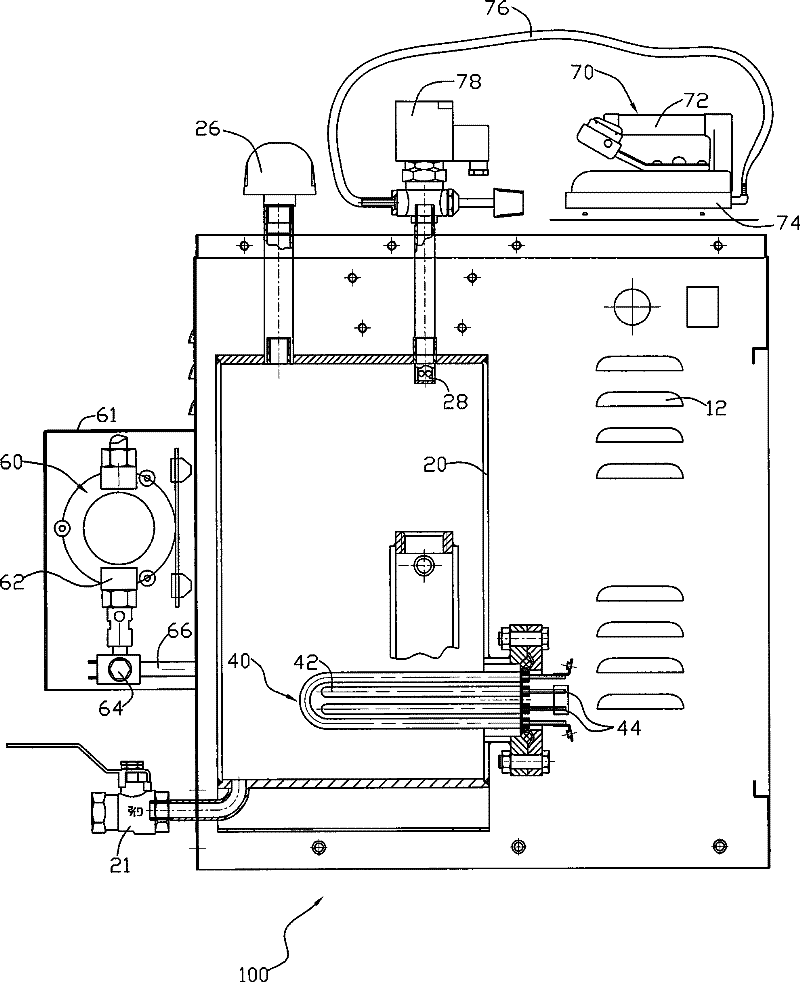

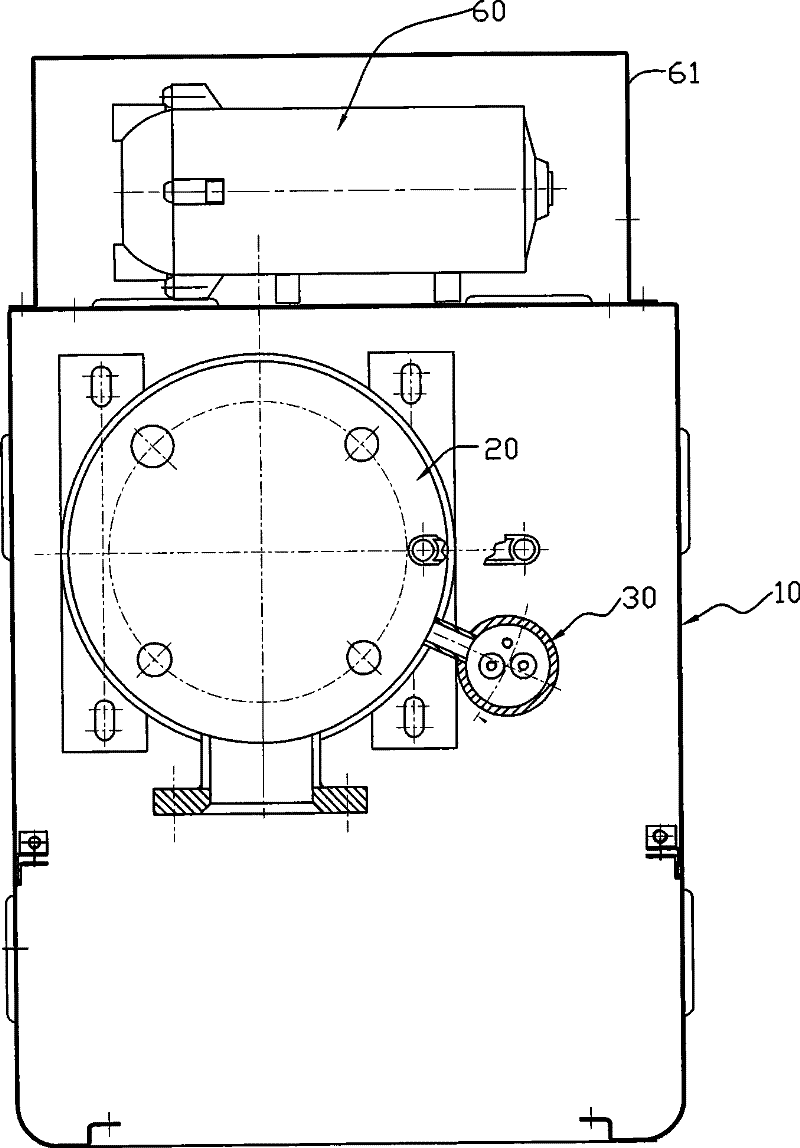

[0012] now refer to Figure 1-4 The electric heating steam generator 100 provided by the present invention includes an inner container 20, a water pump 60 for supplying water to the inner container 20, a heating device 40 for heating the water in the inner container 20, and a device for monitoring the water level in the inner container 20. The water level electrode device 30 and the ironing device 70 connected with the inner tank 20 . The inner tank 20 , the heating device 40 and the water level electrode device 30 are all accommodated in a rectangular casing 10 , and a plurality of cooling holes 12 are opened on the casing 10 ; and the water pump 60 is installed outside the casing 10 .

[0013] The inner tank 20 is in the shape of a cylinder, and its bottom communicates with a drain valve 21 for discharging the waste water in the inner tank 20 after the steam generator 100 is used. A safety valve 26 is installed on the top of the inner tank 20, and when the steam pressure in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com