Wire-winding screw and method for preparing same

A winding and spiraling technology, which is applied in the field of variable-diameter spiral wound by wire and its preparation, can solve the problems that cannot meet the needs of throttling of fast reactor element rods, and achieve excellent wire surface quality and roughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

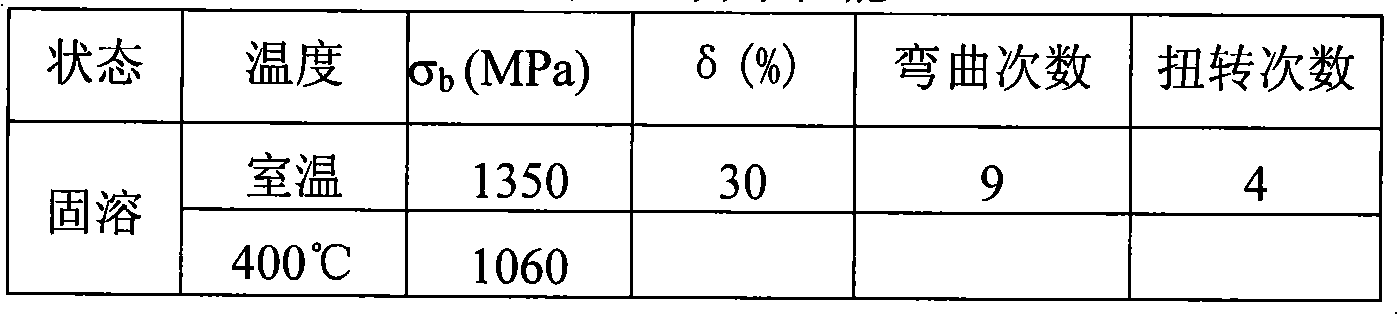

[0038] The technical scheme provided by the invention is used to prepare a wire-wound variable-diameter spiral for a sodium-cooled fast reactor stainless steel reflection layer assembly.

[0039] Concrete preparation steps are as follows:

[0040] (1) According to the following composition and weight ratio, and use vacuum induction melting furnace and consumable electrode vacuum electric arc furnace to smelt molten steel respectively: 0.04% to 0.08% of C; ≤0.75% of Si; ≤0.02% of P ;≤0.02% S; 1.5%~2.0% Mn; 11.0%~14.0% Ni; 16.0%~18.0% Cr; 2.0%~3.0% Mo; 0.3%~0.5% Ti;≤0.1% ≤0.002% of B; ≤0.035% of N; the rest is Fe. Use pure metals for ingredients, and prohibit the addition of rare earth elements during the smelting process. Use a rod and wire rod rolling machine to make blanks to make stainless steel disc blanks.

[0041] (2) Thermal processing.

[0042] (3) cold drawn.

[0043] (4) Annealing.

[0044] (5) Winding. The polished stainless steel wire in step (9) transitions ...

Embodiment 2

[0048] Proportioning is with embodiment 1. The difference is that during smelting, the first time is smelting in an argon-oxygen furnace, and the second time is electroslag remelting; after winding, heat treatment is carried out at 350 ° C to 380 ° C for 2 to 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com