Method for determining chemical components of coal ash

A technology for chemical composition and determination method, applied in the field of chemical analysis, can solve the problem of time-consuming and other problems, and achieve the effects of simple operation, reasonable sample dosage and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention is described in further detail:

[0031] 1. Embodiment

[0032] The determination method of coal ash chemical composition comprises the following steps:

[0033] A. Coal analysis sample processing: select coal analysis samples, pass through 120-200-mesh molecular sieves, and dry them. The selected coal analysis samples are 8 grams to 15 grams, placed in porcelain ash dishes, and burned at 800 ° C to 900 ° C. After 4 hours to 5 hours, take out the porcelain ash dish, let it cool slightly, and then put it in a desiccator to cool;

[0034] B. Preparation of coal ash samples: Weigh coal ash and microcrystalline fiber with a mass ratio of 1-2:1, mix well, use a tablet press with a pressure of 25T-50T, hold the pressure for 30-80 seconds, and press into coal gray sample;

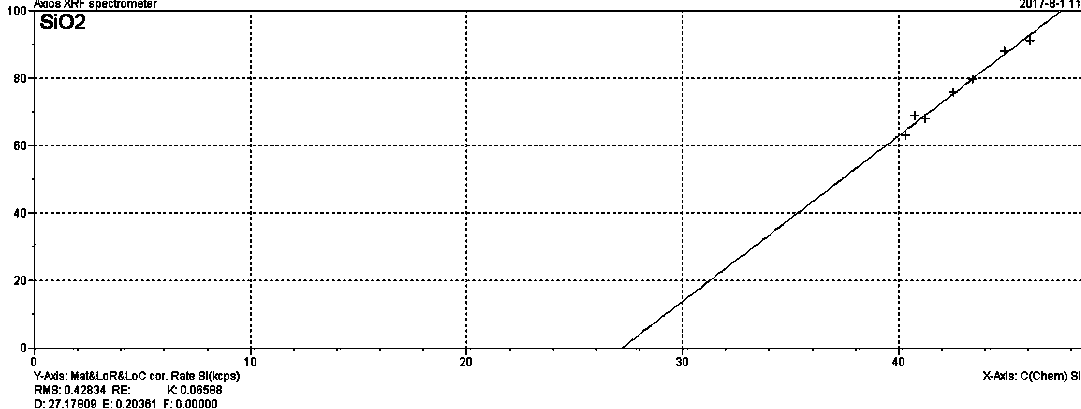

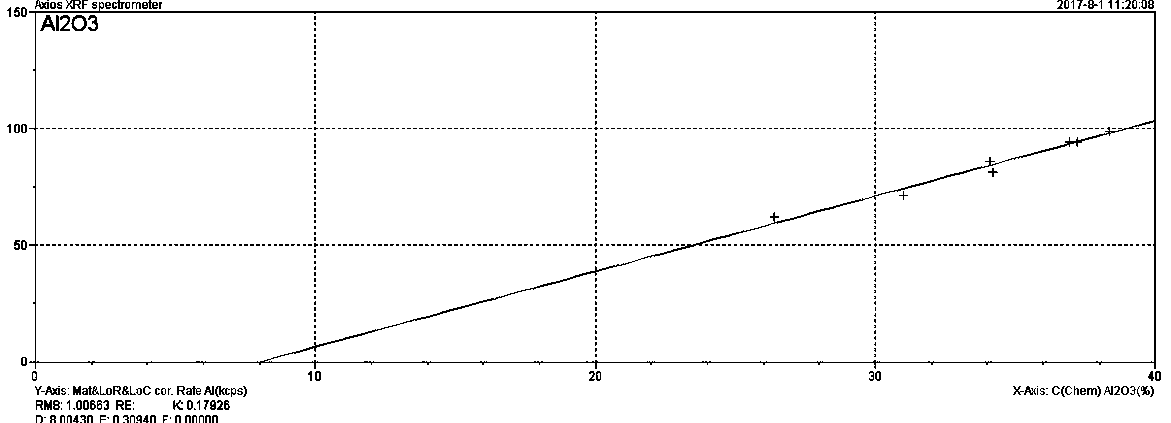

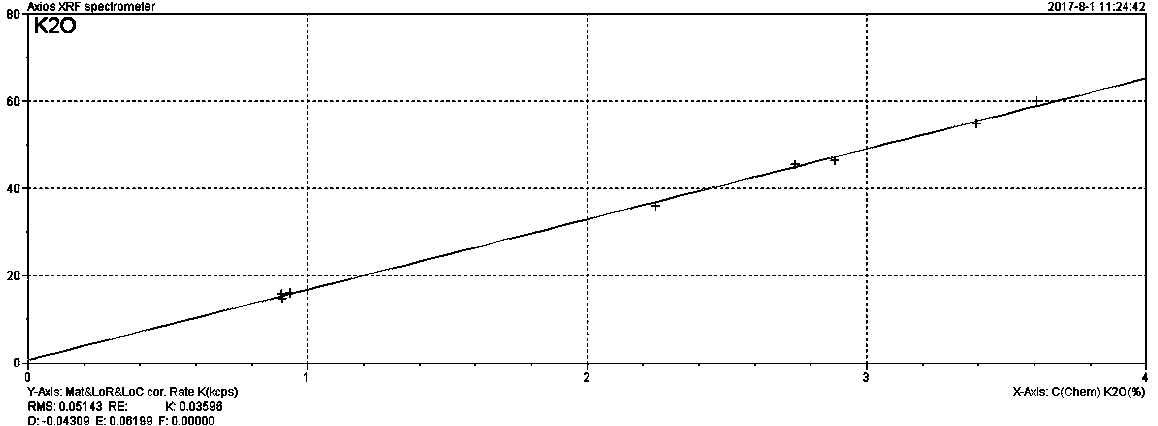

[0035] C. Establish a working curve: use an X-ray fluorescence spectrometer to analyze a standard sample and establish a working curve for each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com