SnO2 thin film of vehicle mounted ethanol detection and preparation method thereof

A thin film and ethanol technology, applied in the field of SnO2 thin film for vehicle-mounted ethanol detection and its preparation, can solve the problems of small particle size of tin oxide, unfavorable large-scale production, unfavorable preparation method, etc., and achieves easy operation, good surface morphology, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

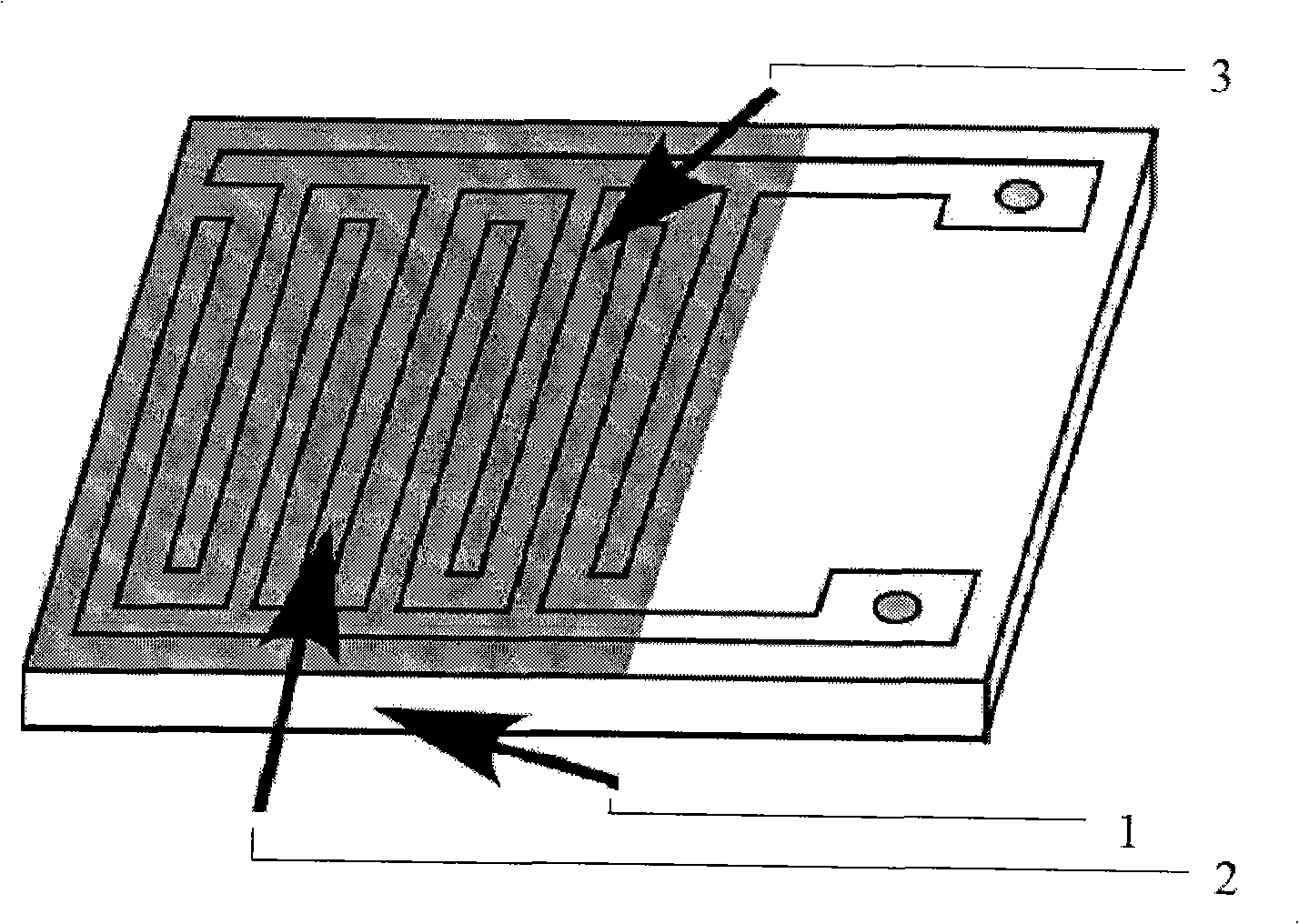

[0038] On-board ethanol detection of SnO 2 The preparation method of the thin film includes electrode preparation, electrode pretreatment, thin film preparation, doping and annealing in implementation, wherein:

[0039] Electrode preparation: the comb-shaped electrode layer 2 is prepared on the silicon substrate 1 by micromachining, photolithography and other technologies;

[0040] Electrode pretreatment: firstly, lead the electrodes, and weld gold wires with gold paste at both ends of the electrodes. Then a layer of 10-20nm carbon film is vaporized on the surface by sputtering to enhance the conductivity of the electrode;

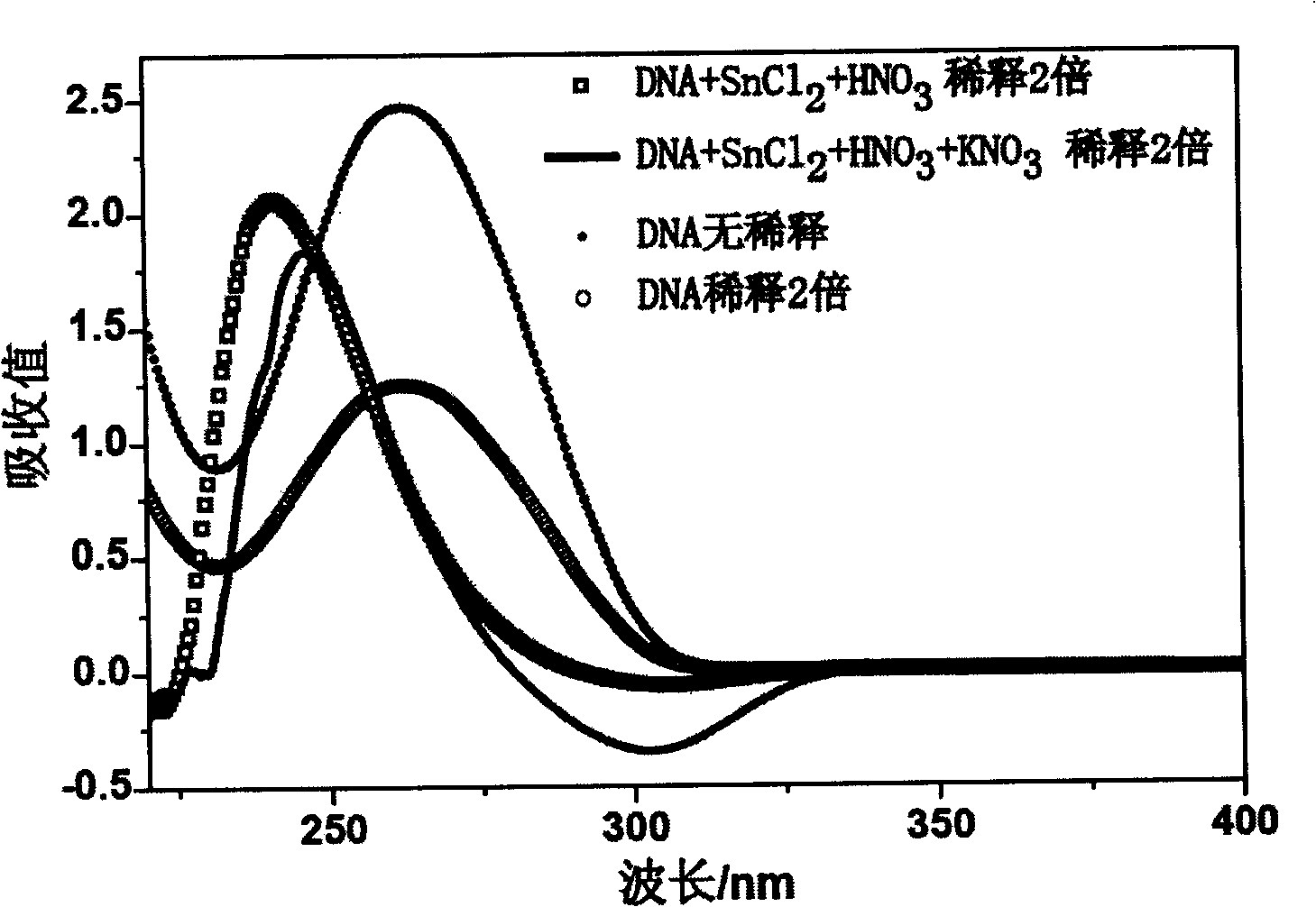

[0041] Thin film preparation: using LK2005 electrochemical workstation, using constant current technology to control the current electrolytic coulometric method for electrodeposition. Electrodeposition conditions: I=0.00016At=7200sCSnCl2=0.02mol / l, CHNO3=0.03mol / l, CKNO3=0.1mol / l, CDNA=0.1mg / l, dry in air;

[0042] Doping and annealing: Sputtering on Sn...

Embodiment 1

[0044] Wash the pretreated comb-shaped electrode layer 2 with ethanol and deionized water respectively, then put the electrode into the electrolytic cell for electrodeposition, the concentration of the electrolyte: CSnCl2=0.02mol / l CHNO3=0.03mol / l CKNO3=0.1mol / l CDNA=0.1mg / l, electrodeposition current: I=0.00008A, electrodeposition time: t=7200s, that is, a layer of SnO is deposited on the electrode surface 2 Thin film sensitive material layer 3. Take out the electrode, dry it in the air, then vaporize a 2nm thick gold layer on the surface of the film by sputtering technology, and finally anneal at 400°C for 2h in high-purity argon to prepare SnO under I=0.00008A current. 2 film.

Embodiment 2

[0046] The pretreated comb-shaped electrode layer 2 is used respectively with ethanol and deionized water to clean the electrode surface, then put the electrode into the electrolytic cell for electrodeposition, the concentration of the electrolyte: CSnCl2=

[0047] 0.02mol / l CHNO3=0.03mol / l CKNO3=0.1mol / l CDNA=0.1mg / l, electrodeposition current: I=0.00016A. Electrodeposition time: t=7200s, that is, a layer of SnO is deposited on the electrode surface 2 Thin film sensitive material layer 3, take out the electrode, dry in the air, then evaporate a 2nm thick gold layer on the surface of the film by sputtering technology, and finally anneal at 400°C for 2h in high-purity argon to prepare SnO under current 2 film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com