Bottom blowing converting furnace for bottom blowing continuous copper smelting

A furnace and copper smelting technology, which is applied in furnaces, electric furnaces, rotary drum furnaces, etc., can solve problems such as insufficient utilization of resources, increased labor and power consumption, and unreasonable use of heat energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

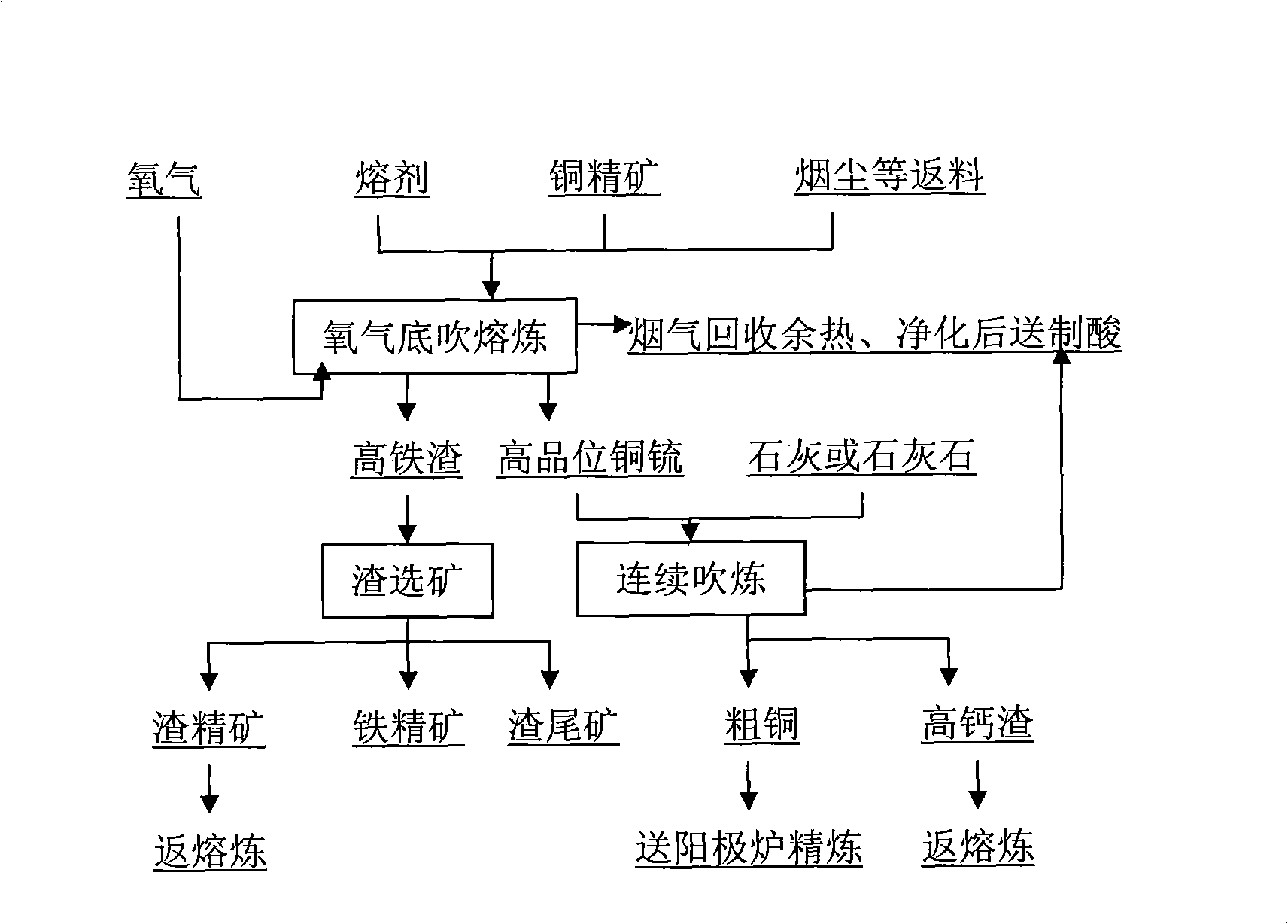

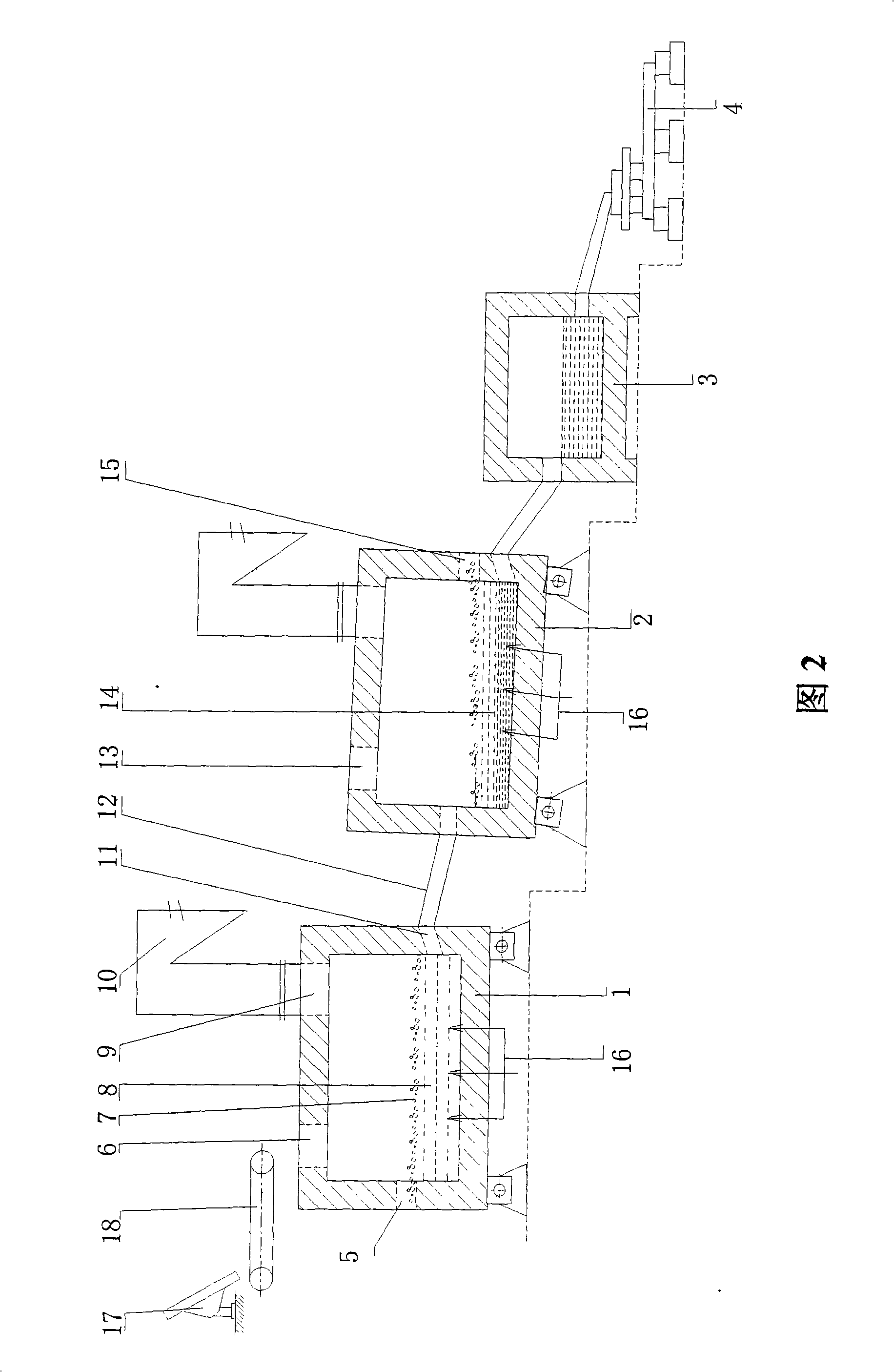

[0093] A technique for continuous copper smelting by oxygen bottom blowing is characterized in that the technique comprises the following steps:

[0094] (1) Copper sulfide concentrate and flux, returned intermediate copper materials including dust, slag copper concentrate, blowing furnace slag, etc., are mixed and granulated by a disc granulator, and sent to the bottom blowing smelting furnace by a belt feeder The upper part of the furnace feed port is fed into the furnace, and oxygen is sent into the furnace through the oxygen spray gun installed at the bottom of the furnace at an angle of 0° to the vertical line for smelting reaction. The temperature is 1080°C;

[0095] (2) The copper matte generated by the bottom-blowing smelting furnace is discharged to the chute connected with the bottom-blowing smelting furnace through the siphon discharge port at one end of the bottom-blowing smelting furnace; the copper matte is sent to the end of the bottom-blowing smelting furnace t...

Embodiment 2

[0101] Oxygen is fed into the furnace through the oxygen lance installed at the bottom of the furnace at an angle of 16° to the vertical for smelting reaction, and oxygen is fed through the oxygen lance installed at the bottom of the bottom blowing furnace at an angle of 16° to the vertical for blowing The mixed pellets are smelted to produce copper matte and smelting slag. The melting temperature is 1100°C and the blowing temperature is 1250°C. Except for the high-temperature flue gas, the others are the same as those described in Example 1.

Embodiment 3

[0103] A process for continuous copper smelting using oxygen bottom blowing, characterized in that:

[0104] Copper matte converting refers to: the liquid high-temperature copper matte produced from the bottom-blown smelting furnace is continuously injected into the bottom-blown converting furnace with oxygen through the chute, and oxygen-enriched air is continuously fed from the bottom of the converting furnace to continuously blow high-grade copper matte ;

[0105] At the same time, the furnace top is not opened, and the flux lime powder is sent into the furnace with oxygen through the silo and metering belt feeder according to the calculation requirements to make slag from the oxygen lance; One end has a hole at the upper part to discharge smelting slag, and a hole at the lower part to set up a siphon device to discharge blister copper to realize continuous addition of copper matte, continuous blowing, continuous addition of flux, continuous slagging, continuous slag discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com