Micro-nanoparticle having special morphology, preparation and use thereof

A particle and morphology technology, which is applied in the field of controllable preparation of micro-nanoparticles, can solve the problems that the controllable synthesis of laser ablation reaction morphology is not very prominent, and achieve the effects of low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

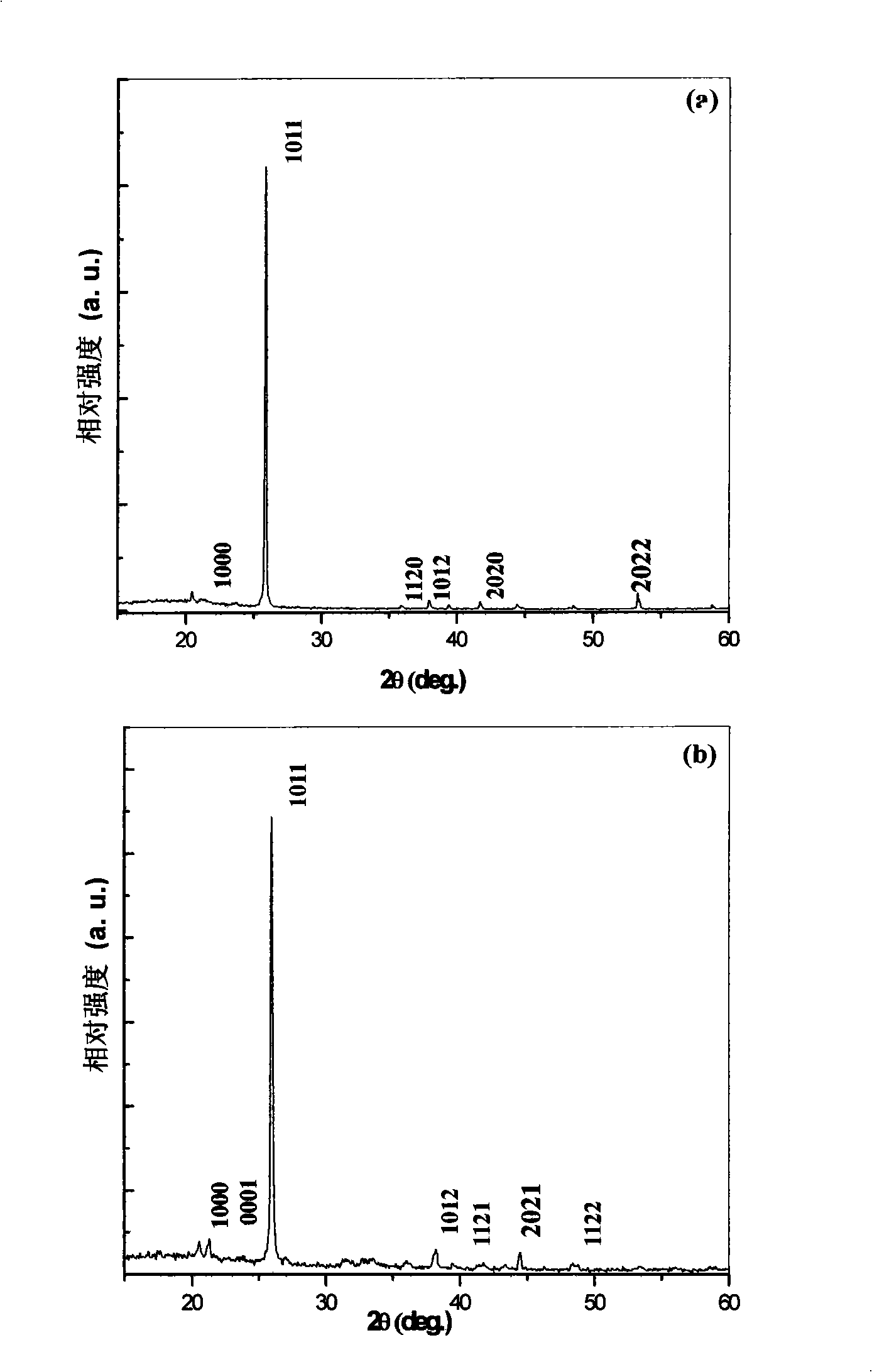

[0029] Such as figure 1 As shown, the equipment of the present invention includes laser 1 (adopting Nd:YAG pulsed laser, laser wavelength 532nm, pulse width 10ns, energy is 2.95mJ, frequency is 5Hz or 10Hz), focusing lens 2 (its focal length is 1000mm), reaction Target 3, base 4, electrode plate 5, quartz container 6, ultrasonic dispersion groove 7; First reaction target 3 is fixed on the base 4 and base is put into quartz container 6 together with reaction target, and around it ( The electrode 5 is arranged as above and below), and then an appropriate amount of liquid phase substance is injected; the entire quartz container is placed in the ultrasonic dispersion tank 7; the pulsed laser light generated from the laser 1 is focused by the focusing lens 2, and the well-converged laser beam is irradiated on the The surface of the target 3 is reacted to form a laser plasma reaction zone.

[0030] The square reaction target is a single crystal germanium block (purity greater than ...

Embodiment 2

[0037] Using the equipment used in Example 1, a high-purity (purity is 99.99%) single crystal germanium reaction target 3 is fixed on the polytetrafluoroethylene base 4, and the base 4 is put into the quartz container 6 together with the reaction target 3 , and then place the quartz container 6 in the ultrasonic dispersion tank 7. Slowly inject pure secondary deionized water into the quartz container 6, and immerse the target in the pure water. The laser optical path is adjusted so that the pulsed laser beam emitted by the laser 1 passes through the focusing lens 2 and then the focused beam is irradiated on the single crystal germanium reaction target 3 . Laser frequency selection 10Hz. In the process of pulse laser ablation, a DC voltage of about 35V is applied to the positive and negative ends of the electrode plate 5, and the ultrasonic dispersion tank 7 is operated at an oscillation frequency of 75kHz, so that the reaction product can be monodispersed. And not easy to re...

Embodiment 3

[0044] Using the equipment used in Example 1, a single crystal germanium block (purity greater than 99.99%) reaction target 3 with a thickness of 5 mm is fixed on the polytetrafluoroethylene base 4, and the base and the target are put into a tempered glass Container 6, and slowly inject high-purity water into the container, and then place the tempered glass container 6 into the ultrasonic dispersion tank 7. Adjust the laser optical path so that the pulsed laser beam emitted by the laser 1 is focused on the upper surface of the single crystal germanium block reaction target after passing through the total reflection mirror and the focusing mirror. A pair of electrode plates 5 are placed on both sides of the reaction target, one left and one right, so as to form a controllable electric field area near the reaction target. The laser frequency is selected as 10Hz or 5Hz. During the pulsed laser ablation process, the ultrasonic dispersion tank was operated at an oscillation freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com