Method for preparing natural squid powder

A squid powder, a natural technology, applied in the field of preparation of pure natural squid powder preparations, can solve the problem of single species, achieve the effects of low moisture content, increase income, and facilitate long-distance transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

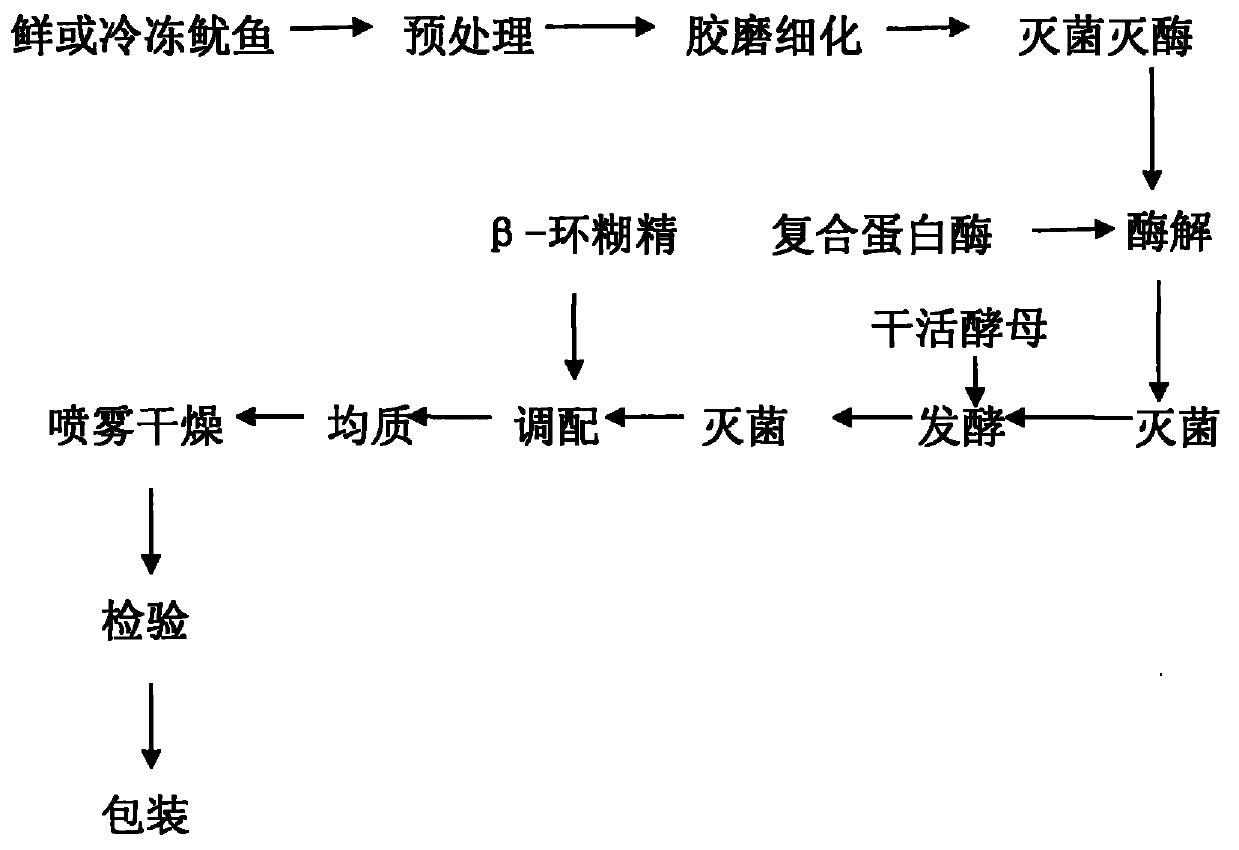

Image

Examples

Embodiment 1

[0019] Remove 100kg of fresh squid from surface impurities, spoiled parts and internal organs of the squid. After beating, put it into the colloid mill to refine the colloid mill. Then put the squid slurry into the reaction kettle and heat it up to 121.5°C to inactivate for 30 minutes. After that, cool down to 55°C. Add 100L of sterile water and 1.2L of 0.25mol / L sodium hydroxide solution to adjust the pH to 7.0; add 0.1kg of complex protease (purchased from Novozymes) and enzymatically hydrolyze for 3 hours. After enzymatic hydrolysis, heat up to 90°C for 30 minutes to inactivate the reaction enzyme; cool down to 30°C, add 0.1kg of dry yeast, keep warm at 30°C for 2 hours; heat up to 100°C for 20 minutes, add 4kg of β-cyclodextrin for preparation; Homogenization and spray drying are carried out again, and the moisture content of the final product is less than 25%. After inspection and packaging, the natural squid powder is made.

Embodiment 2

[0021] Take 100kg of frozen squid that removes surface impurities, spoiled parts and squid viscera. After beating, put it into the colloid mill for fine grinding, then put the squid slurry into the reaction kettle and heat it up to 121.5°C for 30 minutes. After inactivation, cool down to 55°C , respectively adding 100L sterile water and 1.2L 0.25mol / L sodium hydroxide solution to adjust the pH to 7.0; adding 0.3kg compound protease (purchased from Novozymes) for enzymatic hydrolysis for 5h. After enzymatic hydrolysis, heat up to 90°C for 30 minutes to inactivate the reaction enzyme; cool down to 30°C, add 0.1 kg of dry yeast, and keep warm at 30°C for 2 hours; heat up to 100°C for 20 minutes, add 5 kg of β-cyclodextrin for preparation; Homogenization and spray drying are then carried out, and the moisture content of the final product is less than 25%. After inspection and packaging, it is a finished product.

Embodiment 3

[0023] After beating 100kg of fresh squid with surface impurities, spoiled parts and viscera removed, put it into a colloid mill to refine it, then put the squid slurry into the reaction kettle, heat up to 121.5°C for 30 minutes, and then cool down to 55°C. ℃, add 100L sterile water and 0.25mol / L 1.2L sodium hydroxide solution to adjust the pH to 7.0; add 0.5kg compound protease (purchased from Novozymes) for enzymatic hydrolysis for 8 hours. After enzymatic hydrolysis, heat up to 90°C for 30 minutes to inactivate the reaction enzyme; cool down to 30°C, add 0.1kg of dry yeast, and keep warm at 30°C for 2 hours; heat up to 100°C for 20 minutes, and add 8kg of β-cyclodextrin for preparation; Homogenization and spray drying are then carried out, and the moisture content of the final product is less than 25%. After inspection and packaging, it is a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com