Method and device for preparing polysilicon thin-film solar battery

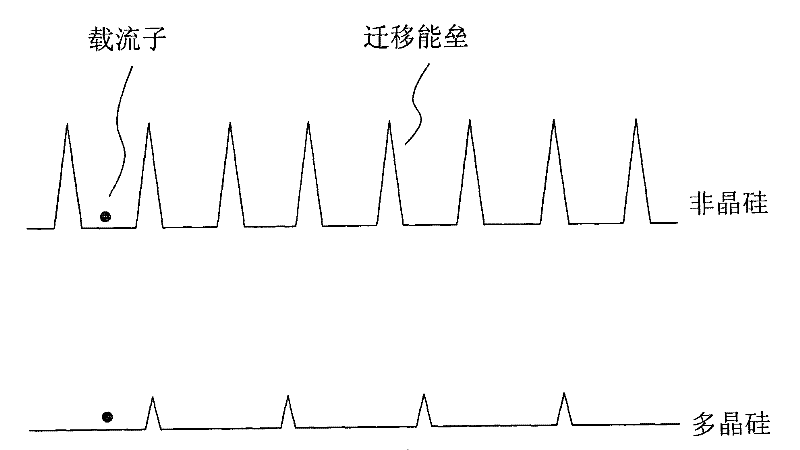

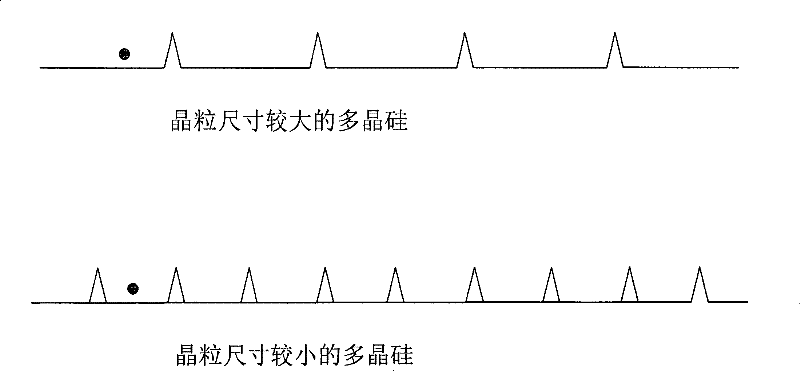

A polysilicon thin film and solar cell technology, which is applied in circuits, electrical components, and final product manufacturing, etc., can solve the problems of low photoelectric conversion efficiency, low carrier mobility, and difficulty in further improving the efficiency of amorphous silicon thin film solar cells. Achieve the effects of high photoelectric conversion efficiency, low cost, and reduced crystal growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

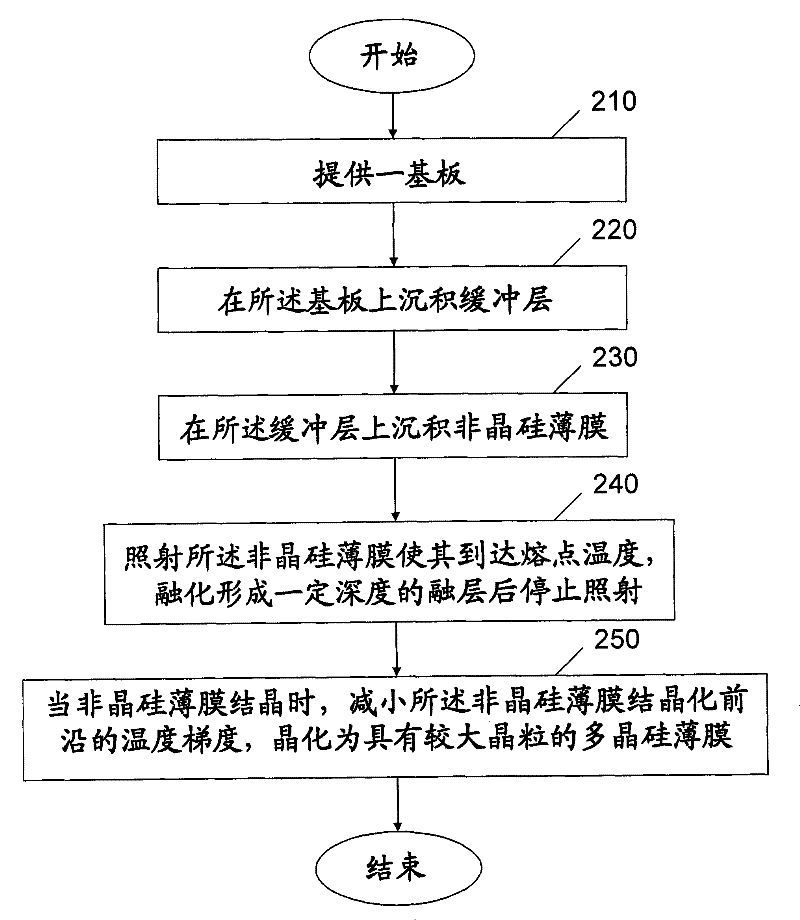

[0030] The invention prepares a high-quality amorphous silicon film on a substrate at a lower temperature and at a lower cost, crystallizes the amorphous silicon film grown on the substrate into a polysilicon film, avoids the harsh process conditions of directly growing a polysilicon film, and further prepares Polycrystalline silicon thin film solar cells. The invention not only reduces the cost of producing solar cells, but also improves the photoelectric conversion efficiency.

[0031] figure 2 Show the method for preparing polysilicon film among the present invention, comprise the following steps:

[0032] In step 110, a substrate is provided, which may be a glass substrate.

[0033] In step 120, a buffer layer is deposited on the substrate, and the buffer layer may be a transparent conductive oxide film.

[0034] In step 130, an amorphous silicon film is deposited on the buffer layer.

[0035] In step 140, the amorphous silicon thin film is irradiated to reach the mel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com