Support lever for greenhouse frame and processing equipment and preparation thereof

A technology of greenhouse skeleton and processing equipment, applied in the directions of botanical equipment and methods, application, frame, etc., can solve the problems of poor bonding degree, longer processing time, poor bonding degree of steel pipe, etc., to increase corrosion resistance and strength, Increase strength and toughness, good effect of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

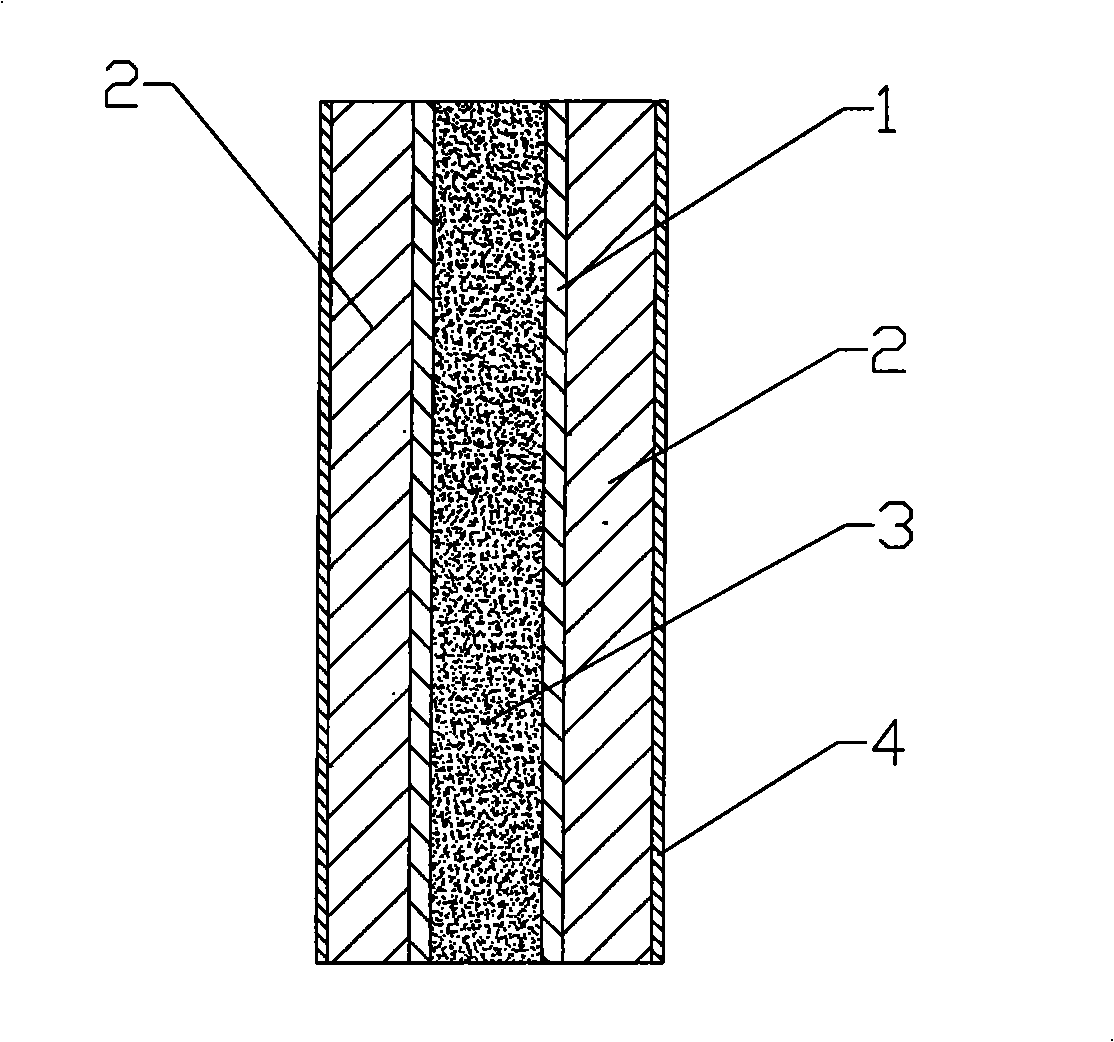

[0048] Embodiment 1, as figure 1 As shown, a support rod for a greenhouse framework includes a metal framework layer 1, the metal framework layer 1 is an ungalvanized steel pipe, the outside of the metal framework layer 1 is fixed with a reinforcement layer 2, and the inside of the metal pipe 3 is filled with foam The core body 3 is made of material, and the outer layer of the reinforcement layer 2 is provided with an unsaturated resin layer 4 .

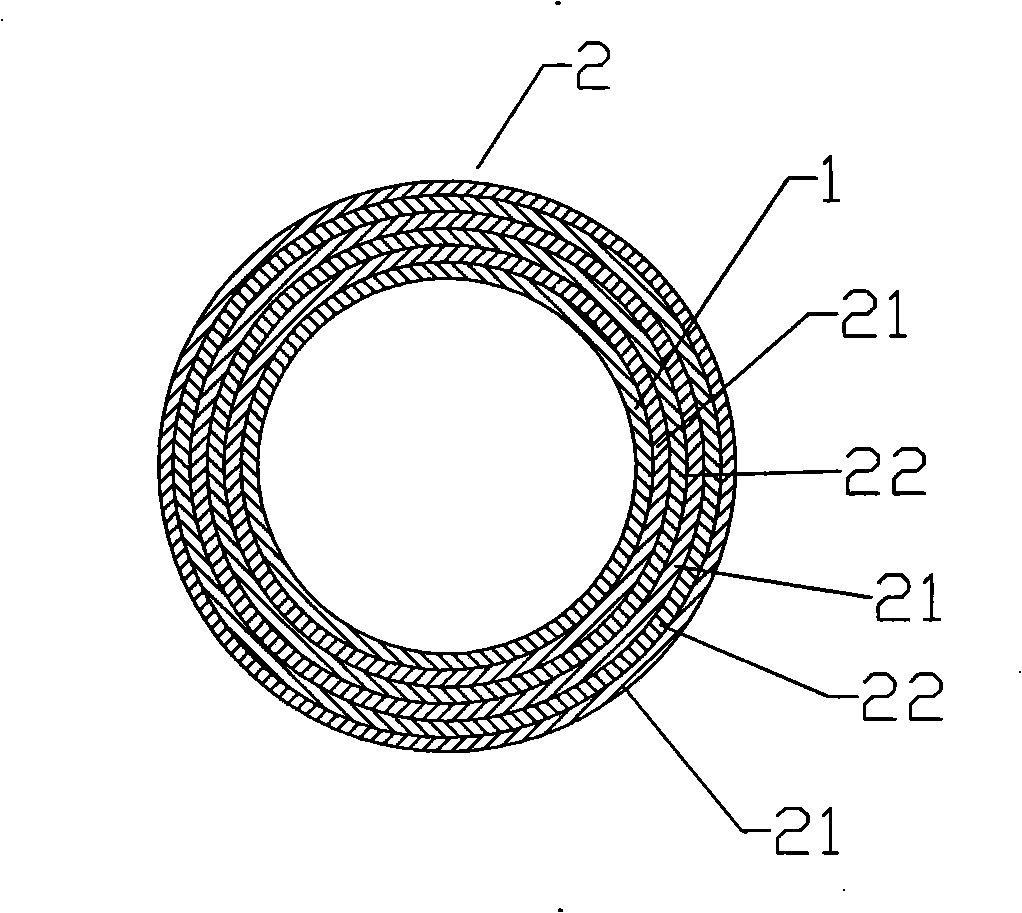

[0049] Such as figure 2 As shown, the reinforcement layer 2 includes a glass fiber cloth layer 22 and a slurry layer 21, the reinforcement layer 2 includes 2 layers of glass fiber cloth layers 22 and 3 layers of slurry layers 21, the glass fiber cloth layer 22 and the slurry layer 21 are arranged at intervals, The glass fiber cloth layer 22 is formed by winding the glass fiber cloth on the metal skeleton layer 1 .

[0050] The core body is formed by foaming polyurethane into the metal skeleton layer, which excludes air and isolate...

Embodiment 2

[0054] Embodiment 2, the difference between embodiment 2 and embodiment 1 is only the difference of the slurry, other structures are the same, the raw material and parts by weight of the slurry are: 1.2 parts of sulphoaluminate cement; 1.2 parts of 150-200 mesh stone powder; 0.0012 parts of German powder; 0.012 parts of polyvinyl alcohol glue with a concentration of 6%.

Embodiment 3

[0055] Embodiment 3, the difference between embodiment 3 and embodiment 1 is only the difference of the slurry, other structures are the same, the raw material and parts by weight of the slurry are: 1 part of sulphoaluminate cement; 1 part of 150-200 mesh stone powder; 0.001 part of German powder; 0.01 part of polyvinyl alcohol glue with a concentration of 6%.

[0056] The thickness of the metal skeleton layer 1 in the above embodiment may be 0.15-0.32 cm, and the thickness of the reinforcing layer 2 may be 0.25-0.5 cm.

[0057] The metal skeleton layer can be a circular or square metal tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com