Optical reading head

An optical reading head and light source technology, applied in the field of optical reading heads, can solve the problems such as the inability to effectively increase the allowable range of the inclination angle, reduce the LED usage and power consumption, and effectively improve the lighting efficiency, so as to improve the lighting efficiency. and identification ability, eliminating the dead angle of identification, and the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

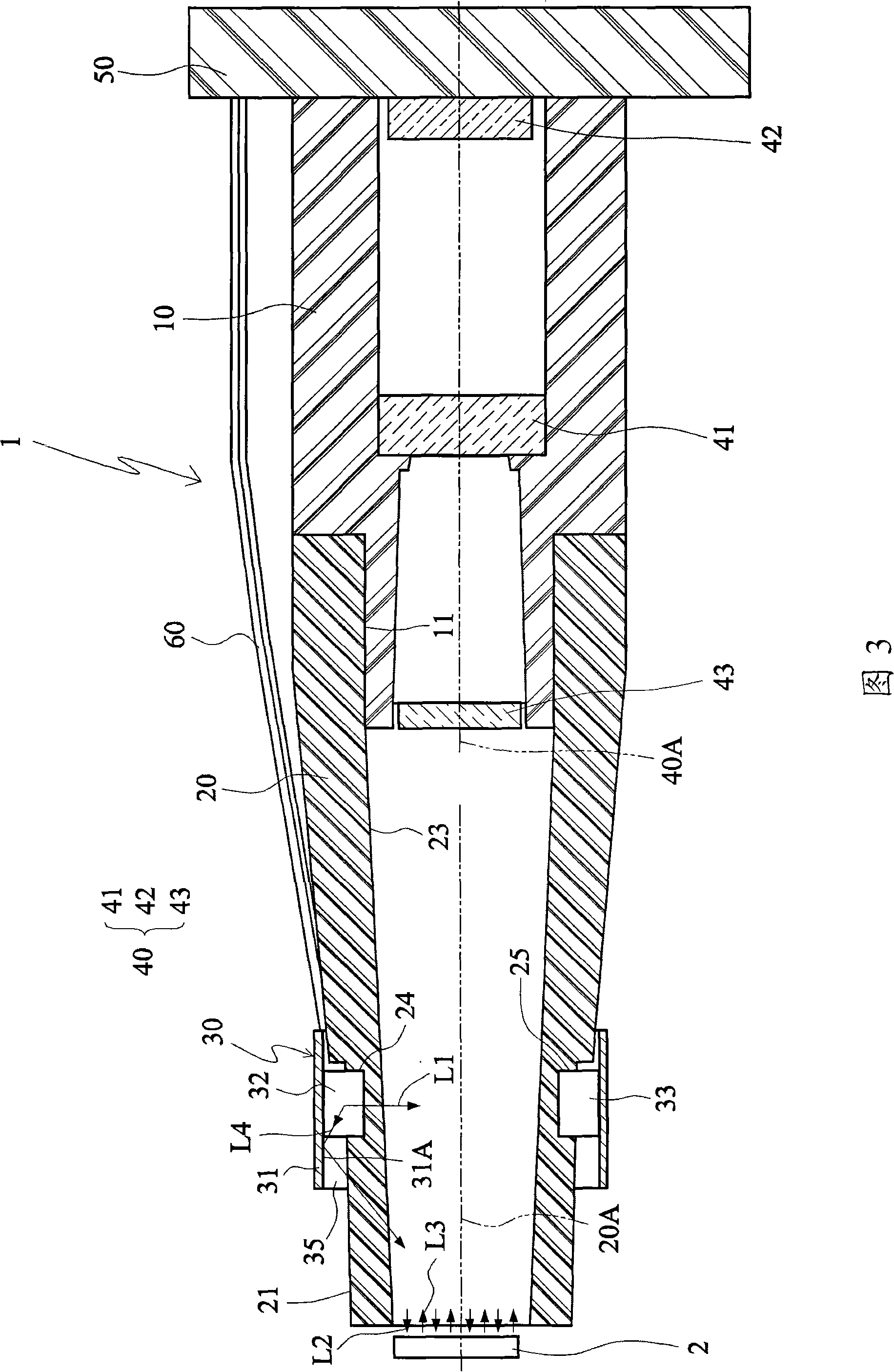

[0060] FIG. 3 is a schematic diagram of the application of the optical pickup head in the first embodiment of the present invention. As shown in FIG. 3 , the optical pickup head 1 of this embodiment is used to read an image of an object 2 . The object 2 is, for example, an electronic book on which a pattern such as a two-dimensional barcode is printed. The optical pickup head 1 includes a casing 10 , a diffusion structure 20 , a light source module 30 and a photosensitive module 40 .

[0061] The diffusing construction 20 is connected to the housing 10 . In FIG. 3 , the diffusion structure 20 can be a hollow body or a hollow tube, and can be used as a light integrating sphere. However, the diffusing formation 20 may also be a solid body or a solid cylinder. Diffuse construction 20 may have a circular, square, or other cross-sectional shape. When the diffusing construction 20 has a circular cross section, the substrate 31 surrounds the diffusing construction 20 more than 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com