Synthesis of constituent-homogeneous spherical lithium tantalite doping polycrystal raw material

A synthesis method, a technology of lithium tantalate, applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth, etc., can solve the problems of difficult control, strong irritation, and difficult to remove ions, and achieve automation, improve Mobility, anti-floating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Synthesis of Lithium Tantalate Polycrystalline Material Doped with Mg(3mol%) Near Stoichiometric Ratio

[0036] (1) Weigh Ta(OH) 5 Ta 2 o 5 ·nH 2 O, add DL-malic acid (C 4 h 6 o 5 , DL-MA) 0.152g, adjust the pH to 7-8 with ammonia water (30%), and filter to remove impurities to obtain a clear and transparent Ta-MA complex solution.

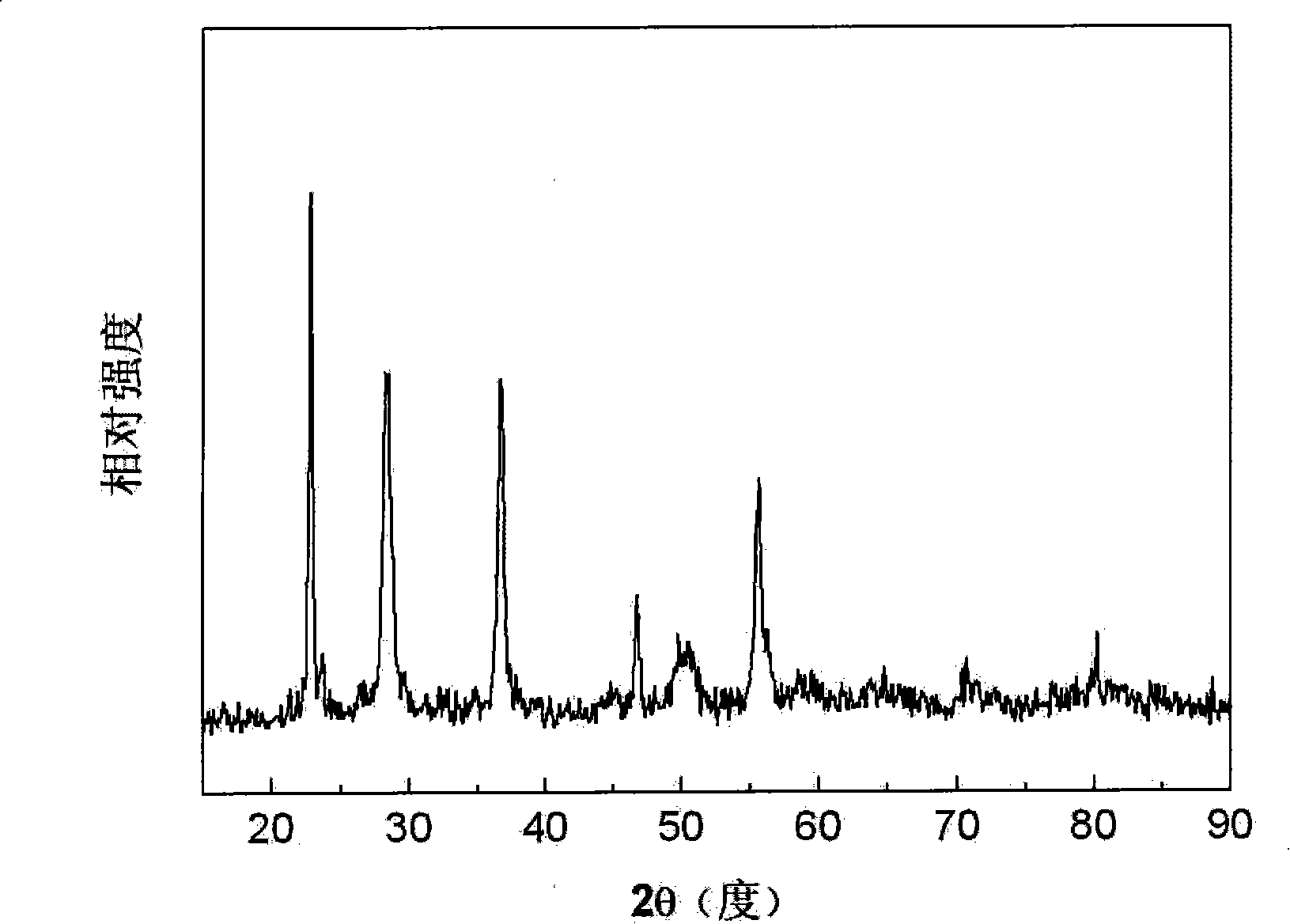

[0037] (2) Use thermogravimetric analysis to test the true concentration of the solution: take 1.875g of Ta-MA solution and calcinate at 750°C for 2h, and calculate the actual concentration of the solution by weighing: 0.0655gTa 2 o 5 / g solution, X-ray diffraction results show that the powder obtained by calcination is Ta 2 o 5 single phase (eg figure 1 shown).

[0038] (3) Ta obtained according to thermogravimetric 5+ The exact amount, according to the equation: 0.97LiOH·H 2 O+0.03MgO+0.485Ta 2 o 5 →M:LiTaO 3 Calculate Li + , The exact amount of MgO.

[0039] (4) Add 0.0682g LiOH·H to the Ta-MA solution 2 O, 0.0020g Mg...

Embodiment 2

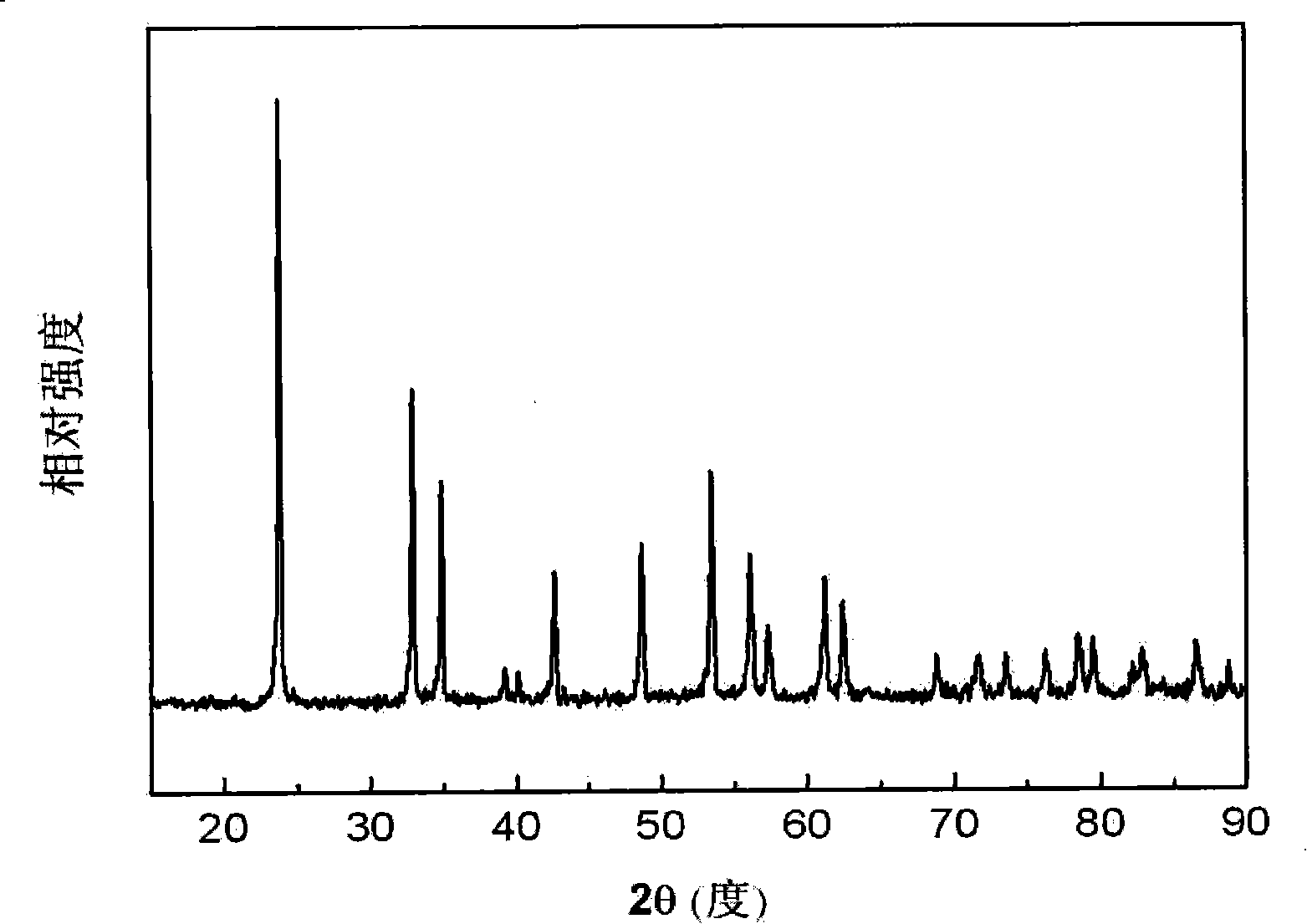

[0042] Example 2: Synthesis of Mg (3mol%) doped near-stoichiometric lithium tantalate polycrystalline material

[0043] (1) Weigh Ta(OH) 5 0.750g was heated and dissolved with 15ml of 36% concentrated hydrochloric acid to prepare highly active Ta 2 o 5 ·nH 2 O, add DL-malic acid (C 4 h 6 o 5 , DL-MA) 0.152g, adjust the pH to 7-8 with ammonia water (30%), and filter to remove impurities to obtain a clear and transparent Ta-CA complex solution.

[0044] (2) Use thermogravimetric analysis to test the true concentration of the solution: Take 2.036g of Ta-MA solution and calcinate at 750°C for 2h, and calculate the actual concentration of the solution by weighing: 0.0681g Ta 2 o 5 / g solution, X-ray diffraction results show that the powder obtained by calcination is Ta 2 o 5 Simplex.

[0045] (3) Ta obtained according to thermogravimetric 5+ The exact amount, according to the equation: 0.97LiOH·H 2 O+0.03MgO+0.485Ta 2 o 5 →M:LiTaO 3 Calculate Li + , The exact amoun...

Embodiment 3

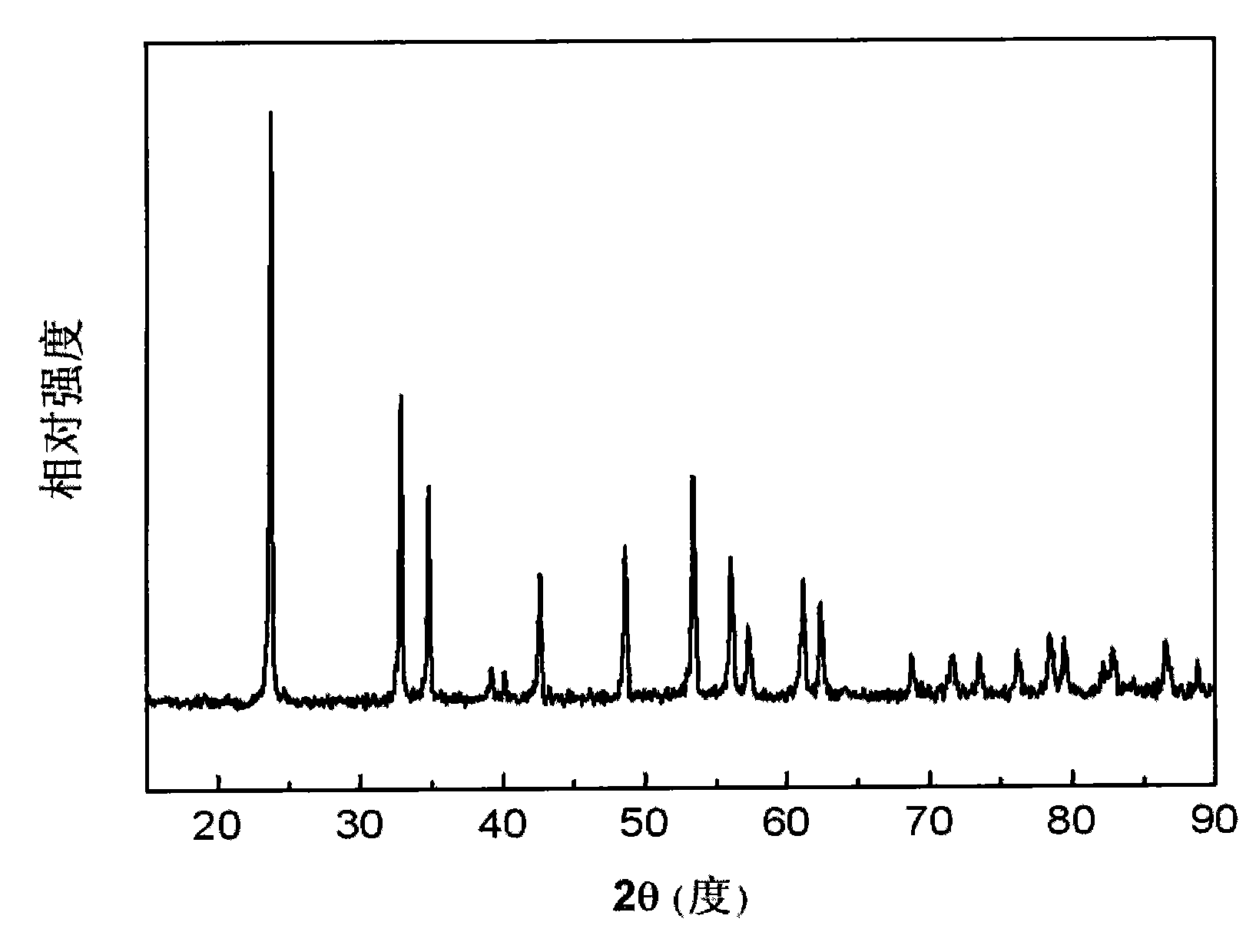

[0048] Example 3: Synthesis of Mg (3mol%) doped near-stoichiometric lithium tantalate polycrystalline material

[0049] (1) Weigh the compound Ta(OH) of tantalum 5 The active Ta 2 o 5 ·nH 2 O, add DL-malic acid (C 4 h 6 o 5 , DL-MA) 0.152g, adjust the pH to 7-8 with ammonia water (30%), and filter to remove impurities to obtain a clear and transparent Ta-MA complex solution.

[0050] (2) Use thermogravimetric analysis to test the true concentration of the solution: take 2.126g of Ta-MA solution and calcinate at 750°C for 2h, and calculate the actual concentration of the solution by weighing: 0.0701g Ta 2 o 5 / g solution, X-ray diffraction results show that the powder obtained by calcination is Ta 2 o 5 Simplex.

[0051] (3) Ta obtained according to thermogravimetric 5+ The exact amount, according to the equation: 0.97LiOH·H 2 O+0.03MgO+0.485Ta 2 o 5 →Mg:LiTaO 3 Calculate Li + , The exact amount of MgO.

[0052] (4) Add 0.0707g LiOH·H to the Ta-MA solution 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com