Manufacturing method of light wood-plastic composite panel

A wood-plastic composite and production method technology, applied in the field of lightweight wood-plastic composite boards, can solve the problems of long-term heating, easy degradation of materials, difficult micropore diameter and distribution, long process flow, etc., and achieve short and shortened molding process. The effect of low production cycle and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

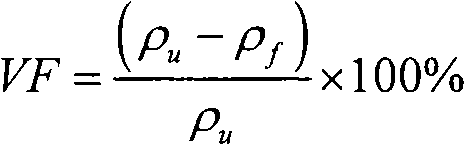

[0035] Put 100 parts of polyvinyl chloride resin powder, 2 parts of epoxidized soybean oil, and 3 parts of 20% chloroprene rubber-dioctyl phthalate / tetrahydrofuran (=1:6) solution into electric heating with an average particle diameter of 120 mesh Mix in a high-speed mixer for 8 minutes, then add 60 parts of dry wood chips with an average particle size of 80 meshes that have been treated with 2% aminosilane ethanol solution (concentration 2%), 4 parts of methylphenyl silicone oil and 4 parts of benzenesulfonate Hydrazide was mixed for another 5 minutes, and when the temperature rose to 60°C, unload; put the mixture into an insulated storage at a constant temperature of 45°C±5°C, relative humidity of 60%, and store for 2 hours.

[0036] Put the stored mixture into a plastic mold cavity that has been preheated to a constant temperature of 85°C±5°C, the thickness of the sheet is 2cm, and the area is 1m×2m. Press at 10Mpa for 10 minutes, deflate twice in the middle, then keep the ...

Embodiment 2

[0039] Put 100 parts of ultra-high molecular weight polyethylene powder with an average particle size of 60 mesh, 3 parts of naphthenic oil, and 2 parts of ethyl silicone oil into an electric heating kneader and mix for 5 minutes, then add 70 parts of used 2% vinyltriethoxysilane ethanol solution (concentration 3%) treated dry chaff and then mixed for 3 minutes, when the temperature rose to 60 ° C, unloading; put the mixture into the heat preservation storage, constant temperature 60℃±5℃, relative humidity 55%, store for 20 hours.

[0040] Put the stored mixture into a plastic mold cavity that has been preheated to a constant temperature of 120°C±5°C, the thickness of the sheet is 1cm, and the area is 1m×1m. Press at 6MPa for 5 minutes, deflate once in the middle, then keep the pressure at 5MPa, and cool for 3 minutes to obtain a lightweight high molecular weight polyethylene wood-plastic composite board.

[0041] The hole diameter of the open-cell microporous composite sheet...

Embodiment 3

[0043] Put 100 parts of copolymerized polypropylene powder with an average particle size of 200 mesh, 2 parts of polypropylene wax and 1 part of montan ester wax into an electric heating kneader and mix for 3 minutes, then add 75 parts of dried bamboo chips with an average particle diameter of 120 mesh and Mix 2 parts of ammonium bicarbonate for another 5 minutes. When the temperature rises to 50±5°C, put it into a plastic model that has been preheated to a constant temperature of 50°C±5°C, the thickness of the sheet is 1.5cm, and the area is 2m×1m. In the cavity, close the mold, and use a hydraulic press to mold at a temperature of 190°C±5°C and a pressure of 15Mpa for 7 minutes without releasing air in the middle, then keep the pressure at 5MPa, and cool for 3 minutes to obtain a lightweight polypropylene wood-plastic composite board.

[0044] The hole diameter of the open-cell microporous composite sheet is 0.1-10um, the porosity is 20%±5%, and the static bending strength is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com