Absorbent charcoal based catalyst for hydrolyzation and catalysis of carbonyl sulphur in low-temperature and preparation method thereof

A technology of activated carbon and carbonyl sulfide, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of high energy consumption, high operating costs, and applicable removal concentration Low range and other problems, to achieve the effect of high breakthrough sulfur capacity and high desulfurization precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A. Take 10 grams of coal-based activated carbon and grind it into 40-60 meshes, wash it with tap water and distilled water for 3 times, and then dry it in a constant temperature drying oven at 120°C for 3 hours;

[0022] B. Use 1 gram of KOH and 1 gram of KMnO 4 , 0.1 g Ce(NO 3 ) 3 and 0.5 g NHVO 3 Prepare 10ml of impregnating solution, put the dry activated carbon in step A into it and impregnate for 10 hours;

[0023] C. Dry the impregnated activated carbon in step B in a constant temperature drying oven at 120°C for 3 hours, then put it into a tube furnace, and dry it at 300°CN 2 Activated under protection for 4 hours to obtain an activated carbon-based catalyst.

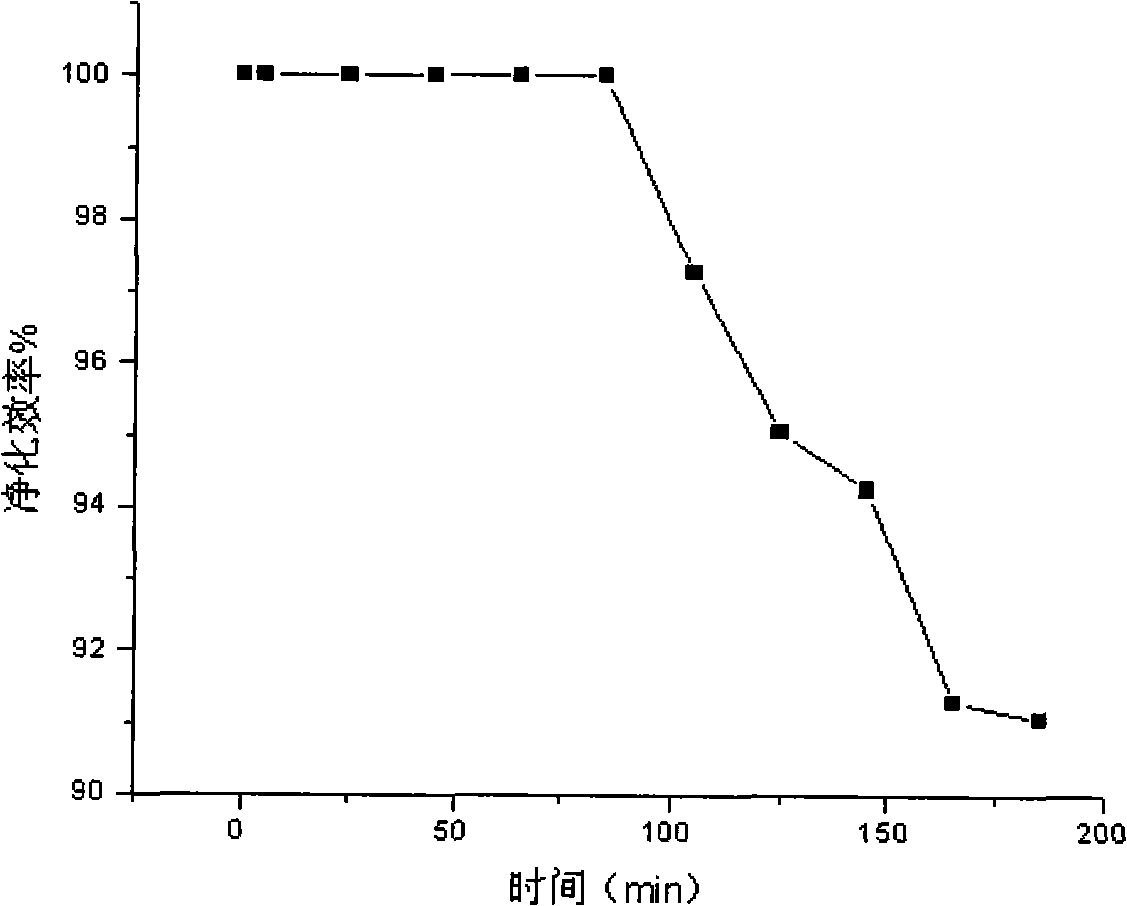

[0024] When the obtained activated carbon-based catalyst is used to remove COS, the catalyst is installed in a fixed bed reactor (Φ8mm×200mm), and the reaction conditions are: activated carbon-based catalyst 3.00g, temperature 50°C, space velocity 1000h -1 , COS concentration 590ppm, oxygen concentrat...

Embodiment 2

[0027] A. Take 10g of wood-based activated carbon and grind it into 40-60 meshes, wash it twice with tap water and distilled water, and then dry it in a constant temperature drying oven at 100°C for 4 hours;

[0028] B, with 0.5 grams (NH 4 ) 6 mn 7 o 24 and 0.5 g KOH, 0.01 g dinuclear cobalt phthalocyanine sulfonate and 0.5 g MnAc 2 Prepare 10m impregnating liquid, put the activated carbon of step A into it and impregnate for 6 hours;

[0029] C. Dry the impregnated activated carbon in step B in a constant temperature drying oven at 100°C for 6 hours, then put it into a tube furnace, and dry it at 500°CN 2 Activated under protection for 2 hours to obtain an activated carbon-based catalyst.

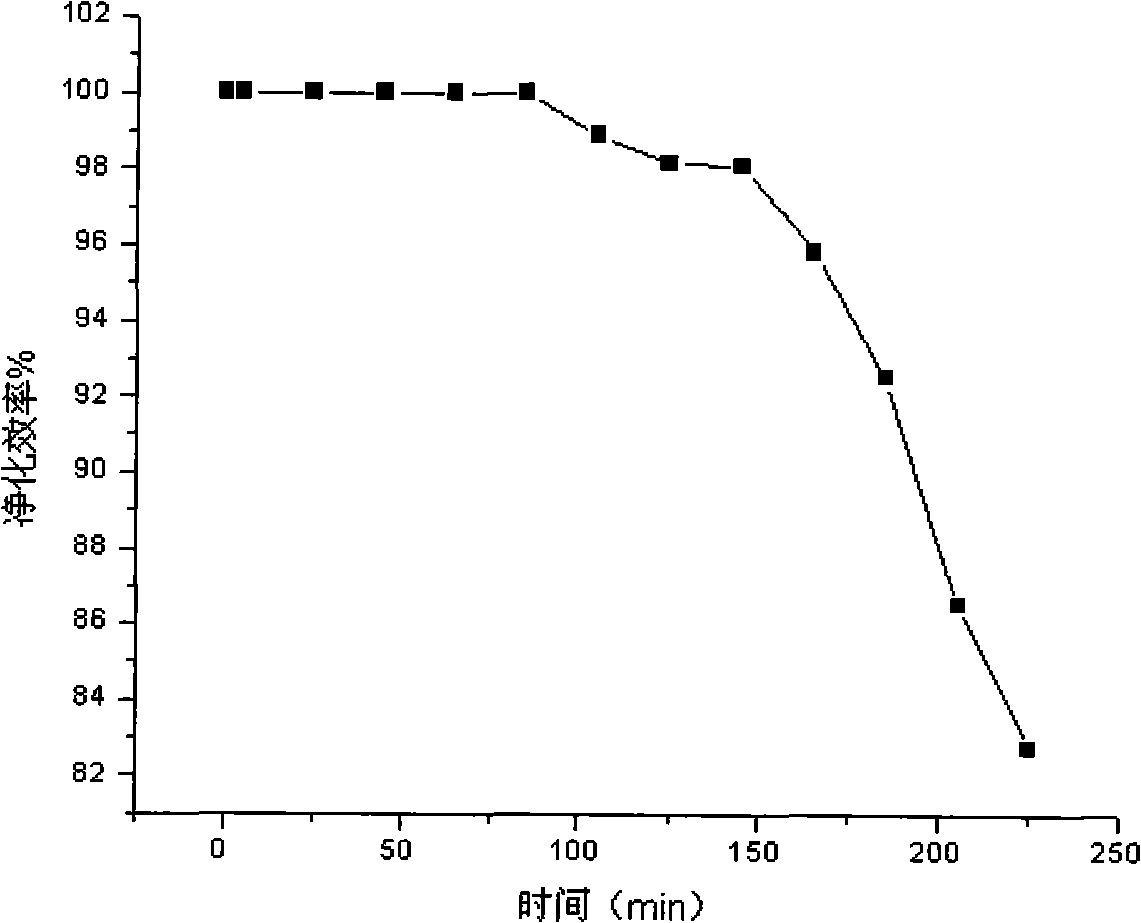

[0030]When using the obtained activated carbon-based catalyst to remove COS, the catalyst is installed in a fixed-bed reactor (Φ8mm×200mm), and the reaction conditions are: catalyst 3.00g, temperature 50°C, space velocity 1000h -1 , COS concentration 510ppm, oxygen concentration 0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com