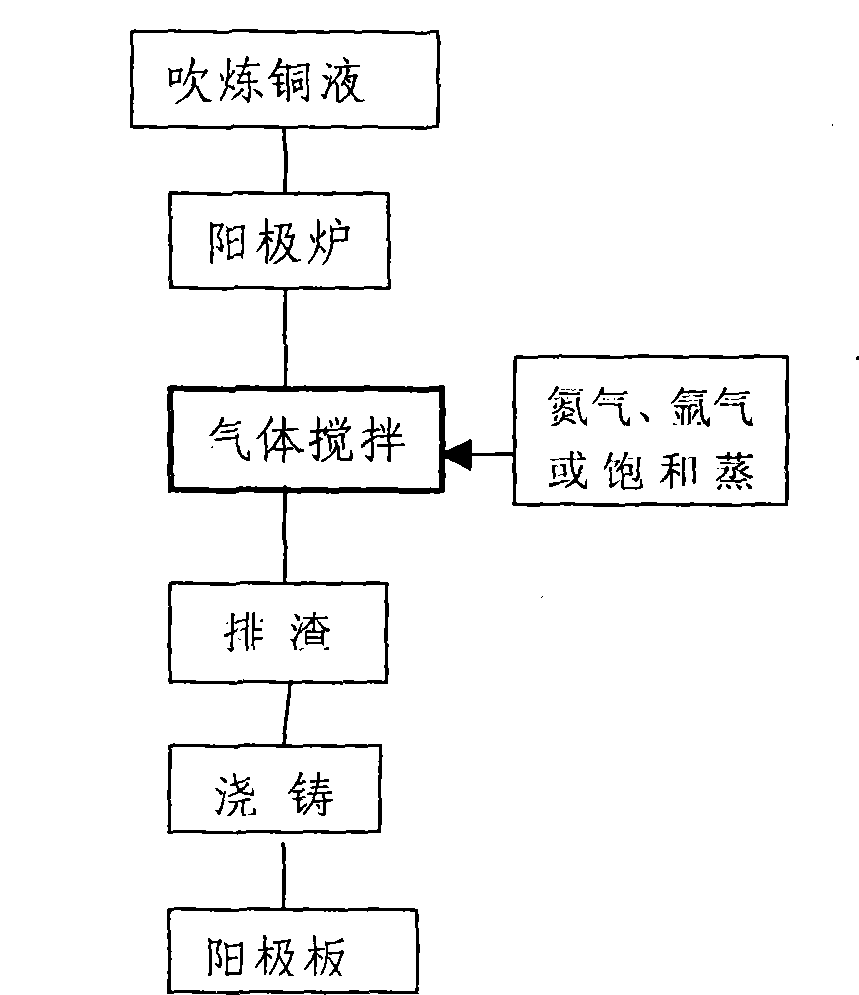

Non-oxidation non-reduction fire refining process for copper

A pyro-refining and non-oxidation technology, applied in the field of copper smelting, can solve the problems of not fundamentally eliminating black smoke pollution, shortening operation time, and low production efficiency, so as to solve the problem of black smoke pollution and realize zero emission of black smoke , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

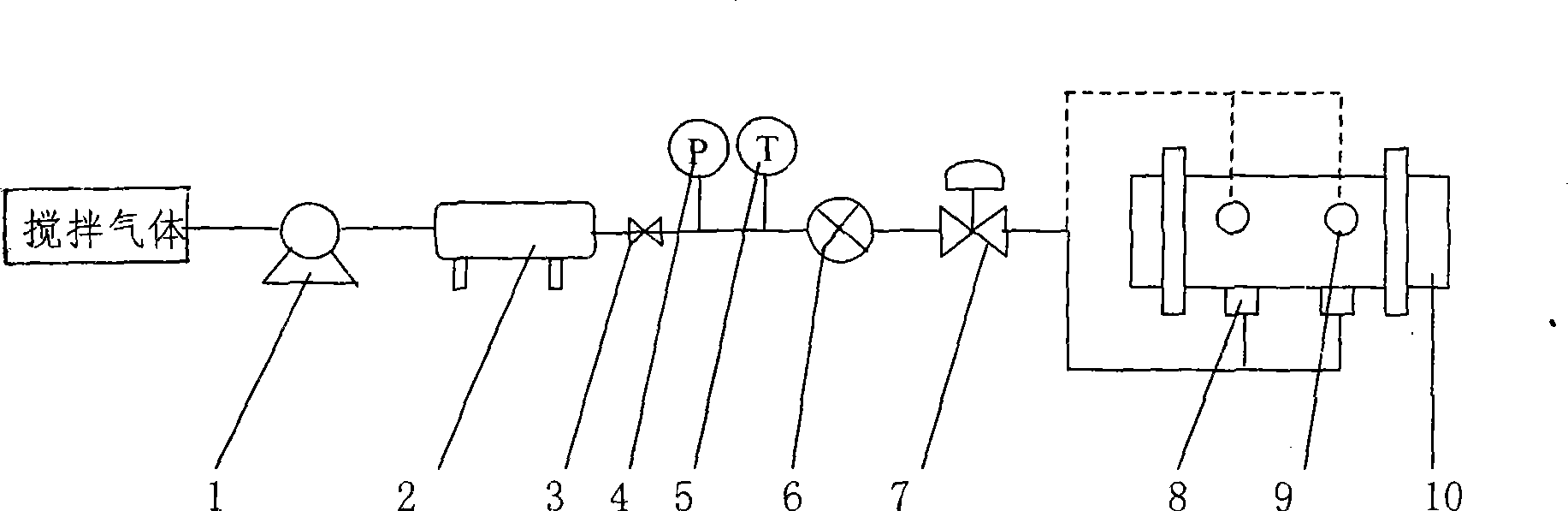

[0018] As shown in Figures 1 and 2, the blowing copper liquid with an oxygen content of 0.05-0.30% is put into the rotary anode furnace 10, and the stirring gas is sent into the gas storage tank 2 through the compressor 1, and is decompressed by the pressure reducing valve 3. Pressure to 0.2 ~ 0.8MPa, observe the pressure gauge 4, thermometer 5 and flow meter 6, adjust the gas flow to 50 ~ 3000Nm with the regulating valve 7 3 / h, the gas enters the copper liquid through the breathable brick 8 at the bottom of the furnace for stirring operation to the end, and the number of breathable bricks is determined according to the size of the furnace. In addition, the stirring gas can also be passed into the side tuyere 9 of the rotary anode furnace 10 to enter the copper liquid for stirring operation. The stirring gas used is argon (Ar≥96%), nitrogen (N 2 ≥96%), one or more mixtures of saturated steam, gas temperature: 25-120°C for argon or nitrogen, 143-170°C for saturated steam. Du...

Embodiment 2

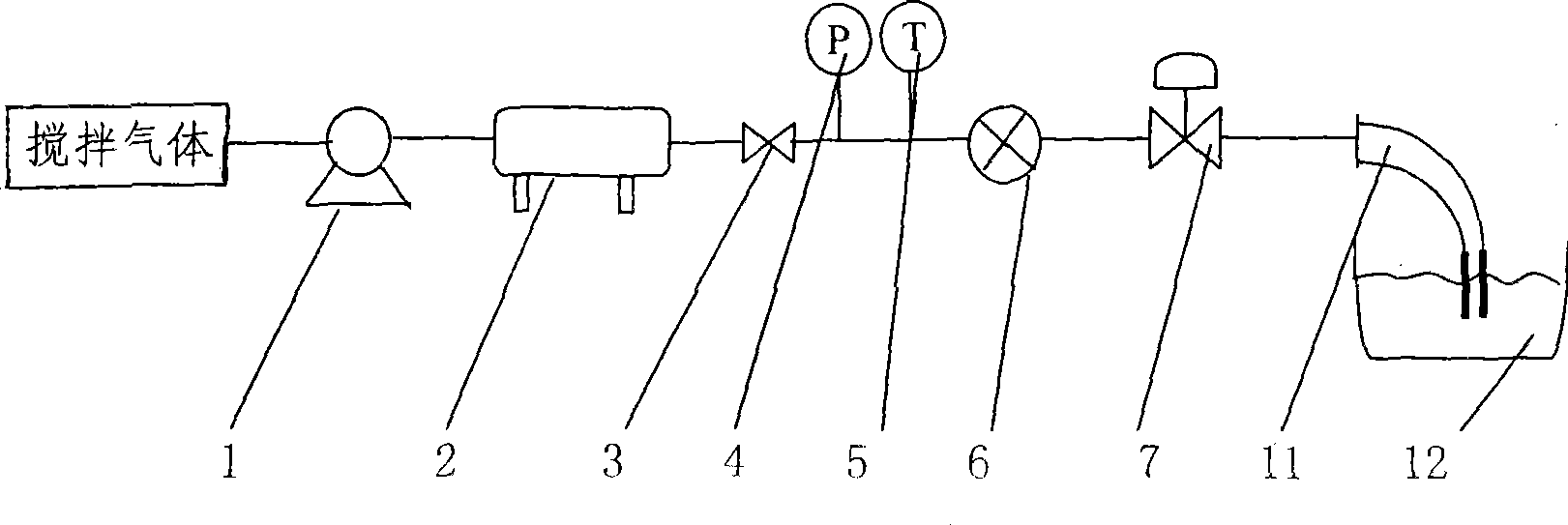

[0020] As shown in Figure 3, the blowing copper liquid with an oxygen content of 0.05% to 0.30% is put into the reflective anode furnace 12, the stirring gas is input into the gas storage tank 2 through the compressor 1, and is decompressed to 0.2% through the pressure reducing valve 3. 0.8MPa, during operation, open the regulating valve 7, observe the pressure gauge 4, thermometer 5 and flow meter 6, and the stirring gas enters the copper liquid through the iron pipe 11 covered with refractory mud at the front end to carry out the stirring operation to the end. Stirring gas type, temperature, flow rate and furnace internal pressure are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com