Method of preparing novel composite aromatic condiment

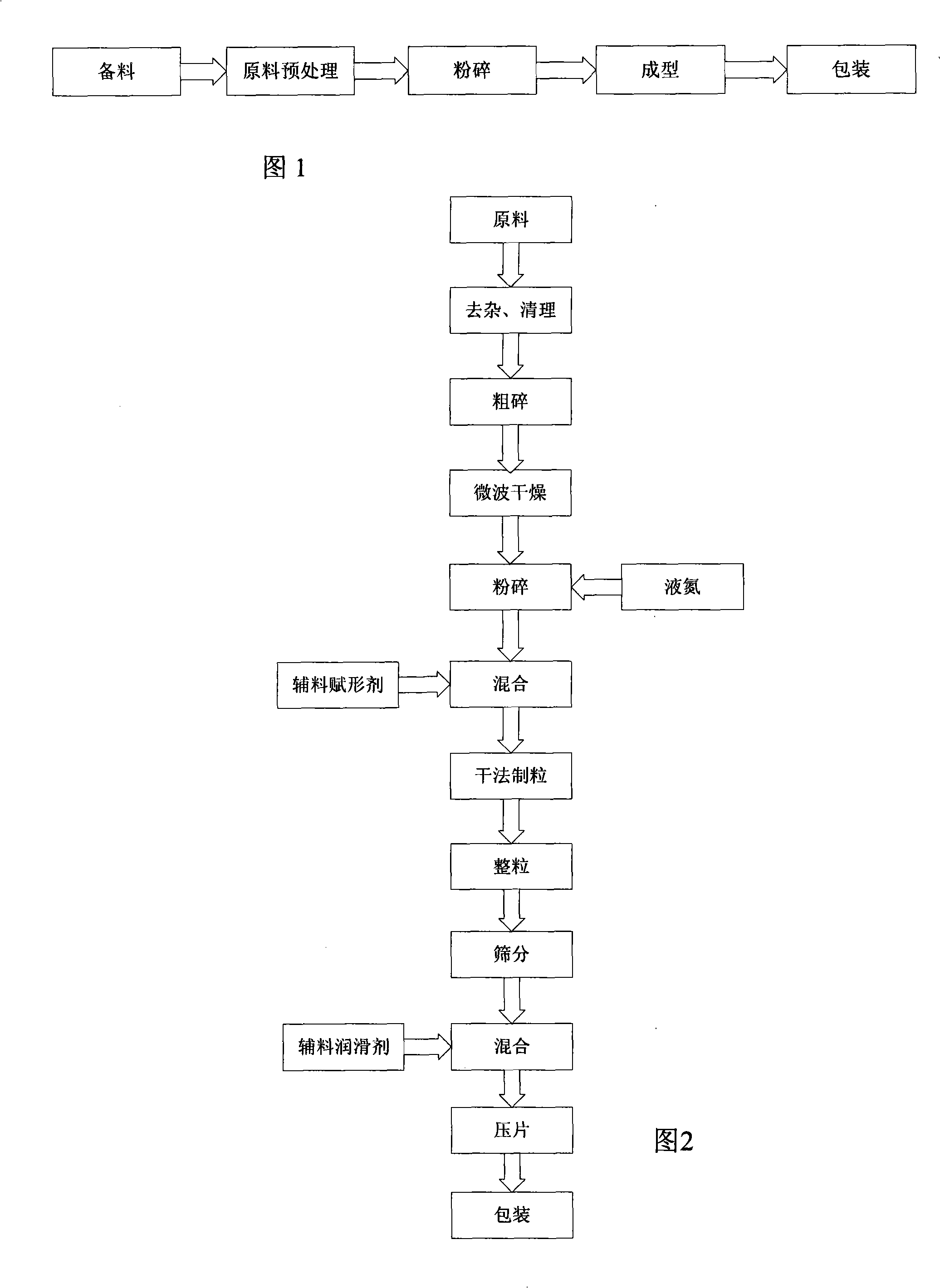

A manufacturing method and technology of spices, applied in the field of condiments, can solve the problems of aroma loss, methods not involved in preventing component loss and oxidation, large component loss, etc., and achieve the effect of maximizing integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

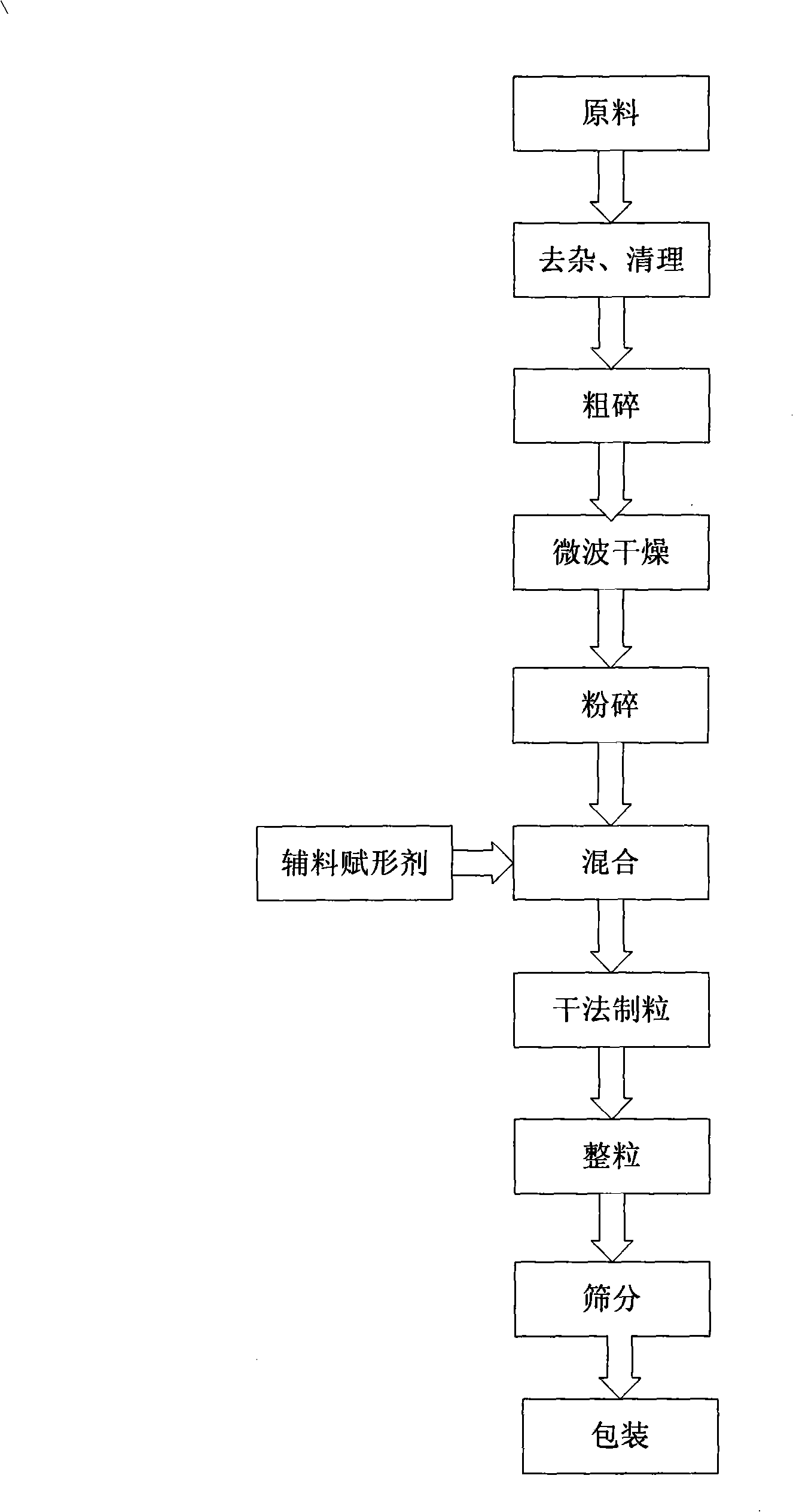

[0082] Embodiment 1: its process flow diagram is shown in Figure 2

[0083] Rotor crushing:

[0084] 500Kg peppers are inspected, removed, and cleaned, and then chopped by a chopper to less than 15mm, dried in a microwave vacuum until the moisture content is less than 7%, and the temperature is less than 50°C. Grinding to 200 mesh and finer than 90% by the rotor pulverizer, and the pulverization temperature (material temperature) is lower than 60°C. Then mix it with 200Kg glucose powder, 200Kg compressible starch, 200Kg lactose powder, and 100Kg calcium carbonate powder, then carry out dry granulation, sizing, and sieving to obtain 20-100 mesh granules, and return the unqualified granules to re-granulate . After the granule is mixed with 5Kg magnesium stearate, it is inserted into a rotary tablet press for tableting to obtain 8mm tablet, tablet weight 0.5g. Aluminum-plastic composite blister packaging is a finished product.

[0085] When the supply of liquid nitrogen is ...

Embodiment 2

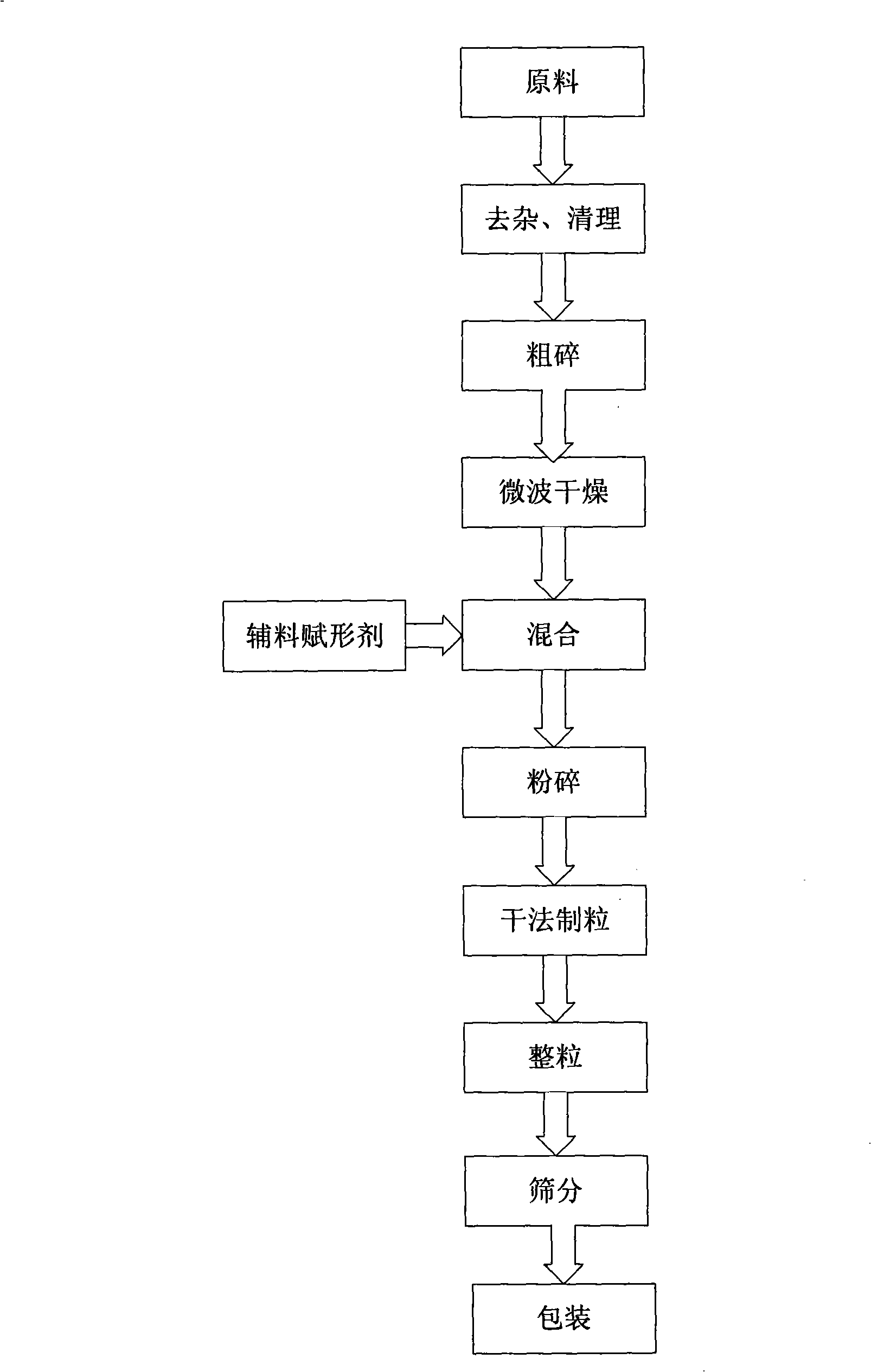

[0086] Embodiment 2: its process flow diagram sees image 3 shown

[0087] Jet smash:

[0088] 500Kg of cinnamon is inspected, removed of impurities and cleaned, and then dried in a microwave vacuum until the water content is lower than 7% and the temperature is lower than 45°C. Thereafter, it is coarsely crushed to below 80 mesh by the rotor pulverizer, and pulverized to 400 mesh to 90% fine by the airflow pulverizer, and the pulverization temperature (material temperature) is lower than 45°C. Afterwards, mix with 400Kg lactose powder and 30Kg calcium carbonate powder, carry out dry granulation, granulation, and sieve to obtain 20-80 mesh granules. The unqualified granules will be returned to granulate again, and the finished product will be packed in aluminum-plastic composite bags under nitrogen protection. .

Embodiment 3

[0089] Embodiment 3: its process flow diagram sees Figure 4 shown

[0090] Vibration crushing (1):

[0091] 500Kg of Zanthoxylum bungeanum is inspected, removed and cleaned, and then coarsely crushed by a rotor mill to less than 3mm, dried in a microwave vacuum until the water content is less than 8%, and the temperature is less than 45°C. After it is mixed with 200Kg sodium glutamate and 150Kg salt, it is pulverized by a vibrating mill to 300 mesh with a fine 95% mixed fine powder. The pulverization temperature (material temperature) is lower than 45°C, and the jacket cooling water temperature is 16°C . Dry granulation, sizing, and sieving of crushed materials to obtain 15-80-mesh granules. The unqualified granules are returned for re-granulation, and nitrogen-protected aluminum-plastic composite bags are used to obtain finished products. Nitrogen protection throughout the whole process from crushing, granulation to packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com