Pagoda double-end opposite pulling screw

A pagoda-style, double-headed technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of easy loosening, poor product confidentiality, affecting the firmness of the fastener and the carrier, and improve confidentiality. versatility, broad versatility, and specificity, the effect of achieving completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

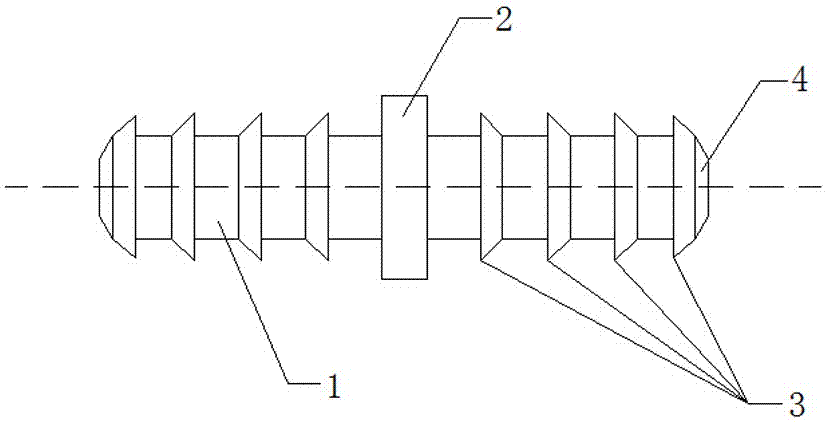

[0013] Embodiment 1: A kind of pagoda-type double-headed pulling screw, its structural schematic diagram is as follows figure 1 As shown, it includes column step 2 and column 1.

[0014] The cylinder 1 is divided into a left cylinder and a right cylinder, which are arranged at both ends of the cylinder step 2 respectively in the form of mirrors, and their structures are identical. Therefore, only the structure of one of the main bodies will be described in detail below.

[0015] A terminal 4 is provided on the top of the cylinder 1, and the section of the terminal 4 is trapezoidal or triangular. When the section of the terminal 4 is trapezoidal, the top of the screw is a flat head, which avoids the damage of the screw to the product shell and plays a role in protecting the shell; when the section of the terminal 4 is triangular, the top of the screw is pointed, The screw can go deep into the product shell under pressure, which increases the fastness, and at the same time, fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com