Method for preparing copper indium selenium compound thin film by continuous ion sheath adsorption reaction method

An adsorption reaction, continuous ion technology, applied in chemical instruments and methods, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as inability to achieve coating, research and application limitations, and achieve good morphology and expanded use. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiment of the present invention uses chemically pure raw materials, the precursor solution is 100ml, the cycle is 100 times, and the heat treatment is at 400°C for 1h under the protection of Ar atmosphere. The substrate is ZnO, indium tin oxide (ITO glass), SnO 2 、TiO 2 , ordinary glass or silicon wafer. See Table 1 for details.

[0025] Table 1

[0026]

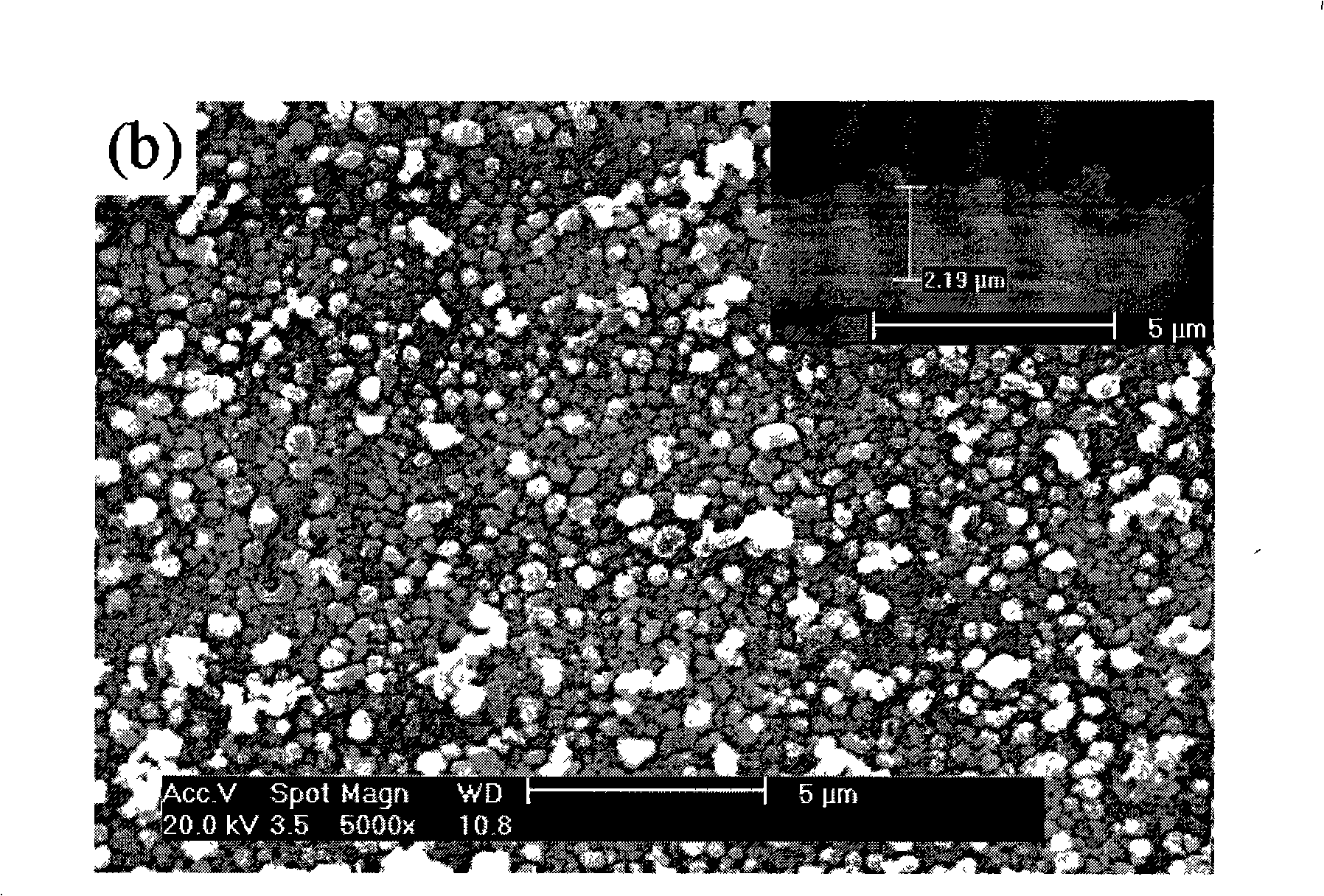

[0027] The materials obtained in the above examples all appear CuInSe 2Phase, by x-ray diffraction (D / MAX-2500x-ray diffractometer) test shows, 1#, 3#, 4# and 6# gained films do not have other miscellaneous phases, by x-ray photoelectron spectrum (Esca MultiplexPhilips-1600x-ray photoelectron spectrum Instrument) test shows, 1#, 4# and 6# film component molar ratio is close to Cu:In:Se=1:1:2. Draw by ultraviolet-visible spectrum analysis (Beckman Du-8B ultraviolet-visible absorption spectrometer), except that the light absorption coefficient of 2# sample is all greater than 10 5 , and the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com