Method for preparing hollow PtPd nano material with cuprous oxide as template

A technology of cuprous oxide and nanomaterials, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of severe redox reaction, rough surface of the final product, inability to accurately copy the shape of the template, etc., and achieve the effect of precise composition control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

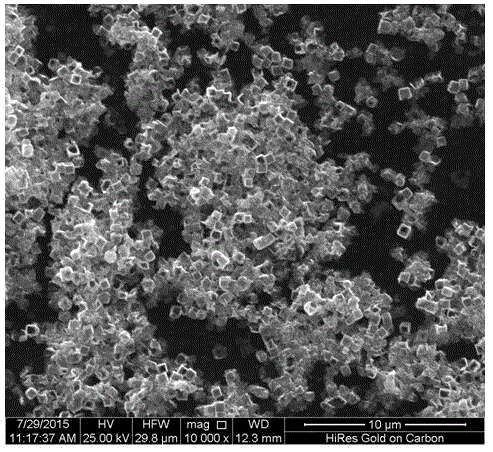

[0029] The method for preparing hollow PtPd nanomaterials using cuprous oxide as a template in Example 1 includes the following steps:

[0030] (1) Disperse 10 mg of cubic structure cuprous oxide uniformly in 10 ml of water ultrasonically, add 20 mM H under stirring at 20°C 2 PtCl 6 Aqueous solution and 33mM Na 2 PdCl 4 Aqueous solution to make the atomic ratio Pt / Pd in the reaction solution 4:1, PtCl 6 2 -And PdCl 4 2 -The molar ratio of the sum to cuprous oxide is 1.4:1, and the reaction is stirred at this temperature for 60 minutes;

[0031] (2) Move the reaction system of step (1) into a heating device and heat it to 60°C at a heating rate of 1°C / min, and continue the reaction at this temperature for 120 minutes;

[0032] (3) After the reaction is completed, the product is centrifuged at 5000 rpm for 5 minutes, 20% ammonia is added to complex to remove the cuprous oxide nucleus, and then 0.1 mol / L nitric acid is added to react at 25°C to remove the copper produced by the disprop...

Embodiment 2

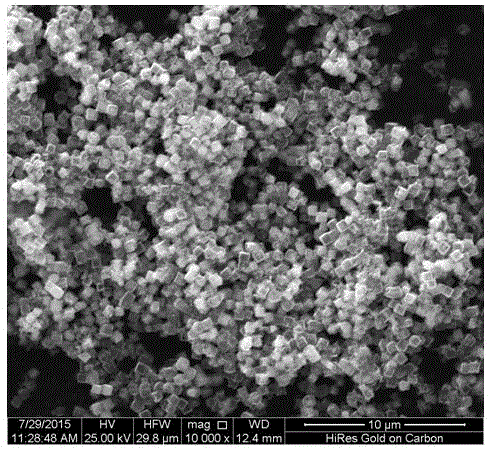

[0034] The method for preparing hollow PtPd nanomaterials using cuprous oxide as a template in Example 2 includes the following steps:

[0035] (1) Disperse 10 mg of cubic structure cuprous oxide uniformly in 10 ml of water ultrasonically, add 20 mM H under stirring at 22°C 2 PtCl 6 Aqueous solution and 33mM Na 2 PdCl 4 Aqueous solution to make the atomic ratio Pt / Pd in the reaction solution 4:1, PtCl 6 2 -And PdCl 4 2 -The molar ratio of the sum to the cuprous oxide is 2.0:1, and the reaction is stirred at this temperature for 50 minutes;

[0036] (2) Move the reaction system of step (1) into a heating device and heat it to 62°C at a heating rate of 2°C / min, and continue the reaction at this temperature for 100 minutes;

[0037] (3) After the reaction is completed, the product is centrifuged at 8000 rpm for 4 min, 25% ammonia water is added to complex to remove the cuprous oxide nucleus, and then 0.2 mol / L nitric acid is added to react at 20°C to remove the copper produced by the d...

Embodiment 3

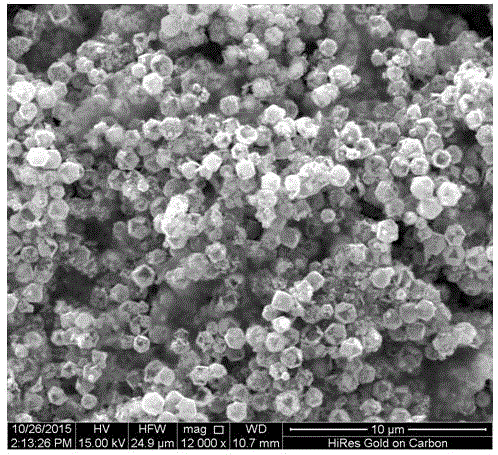

[0039] The method for preparing hollow PtPd nanomaterials using cuprous oxide as a template in Example 3 includes the following steps:

[0040] (1) Disperse 10 mg of cubic structure cuprous oxide uniformly in 10 ml of water ultrasonically, and add 20 mM H under stirring at 25°C 2 PtCl 6 Aqueous solution and 33mM Na 2 PdCl 4 Aqueous solution to make the atomic ratio Pt / Pd in the reaction solution 4:1, PtCl 6 2 -And PdCl 4 2 -The molar ratio of the sum to cuprous oxide is 2.3:1, and the reaction is stirred at this temperature for 30 minutes;

[0041] (2) Move the reaction system of step (1) into a heating device and heat it to 65°C at a heating rate of 3°C / min, and continue the reaction at this temperature for 90 minutes;

[0042] (3) After the reaction is completed, the product is centrifuged at 10,000 rpm for 3 minutes, 25% ammonia is added to complex to remove the cuprous oxide nucleus, and then 0.5 mol / L nitric acid is added to react at 10°C to remove the copper produced by the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com