Method for preparing high-purity heteropoly acid of Keggin structure

A heteropoly acid, high-purity technology, applied in chemical instruments and methods, inorganic chemistry, molybdenum compounds, etc., can solve the problems of low purity of phosphotungstic acid, complicated preparation process, etc., and achieve suitable for large-scale industrial production and product purity High, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 100 grams of sodium tungstate, dissolve it in 150 ml of water, add 16 grams of disodium hydrogen phosphate under stirring, heat to boiling, keep boiling under reflux for 4 hours, and obtain sodium phosphotungstate and phosphotungstic with a concentration of 35.7% by weight acid mixture.

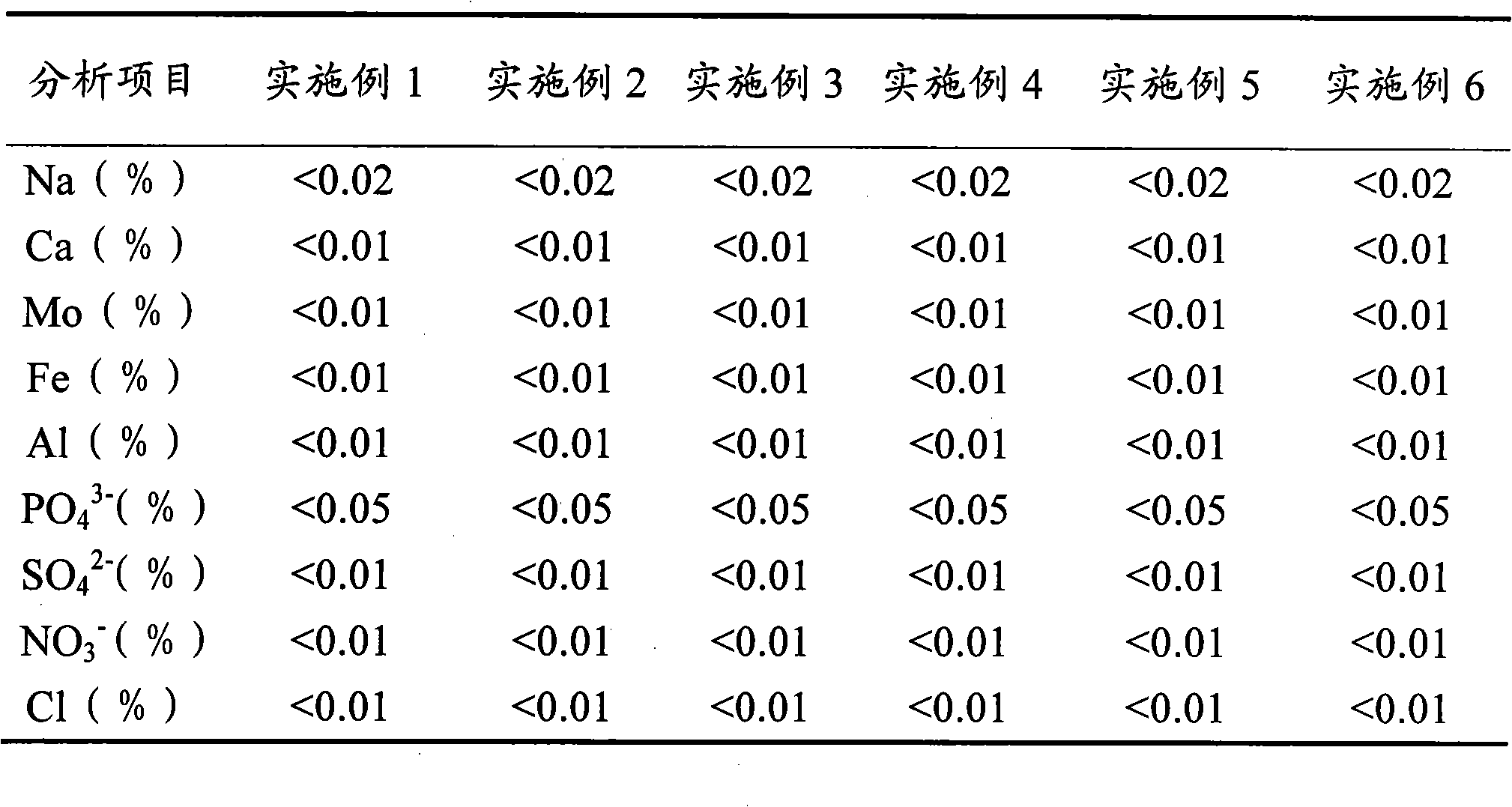

[0036] In order to obtain phosphotungstic acid, add 200 grams of concentrated hydrochloric acid (at this time, the concentration of hydrochloric acid in the system is about 7.2mol / L) to the mixed solution of sodium phosphotungstic acid and phosphotungstic acid at 50°C, cool and precipitate for 12 hours, Filter and dry at room temperature for 5 hours to obtain 73.7 grams of white phosphotungstic acid. 3 PW 12 o 40 .29H 2 O meter, yield is 76.5%. The results of impurity content analysis are shown in Table 1.

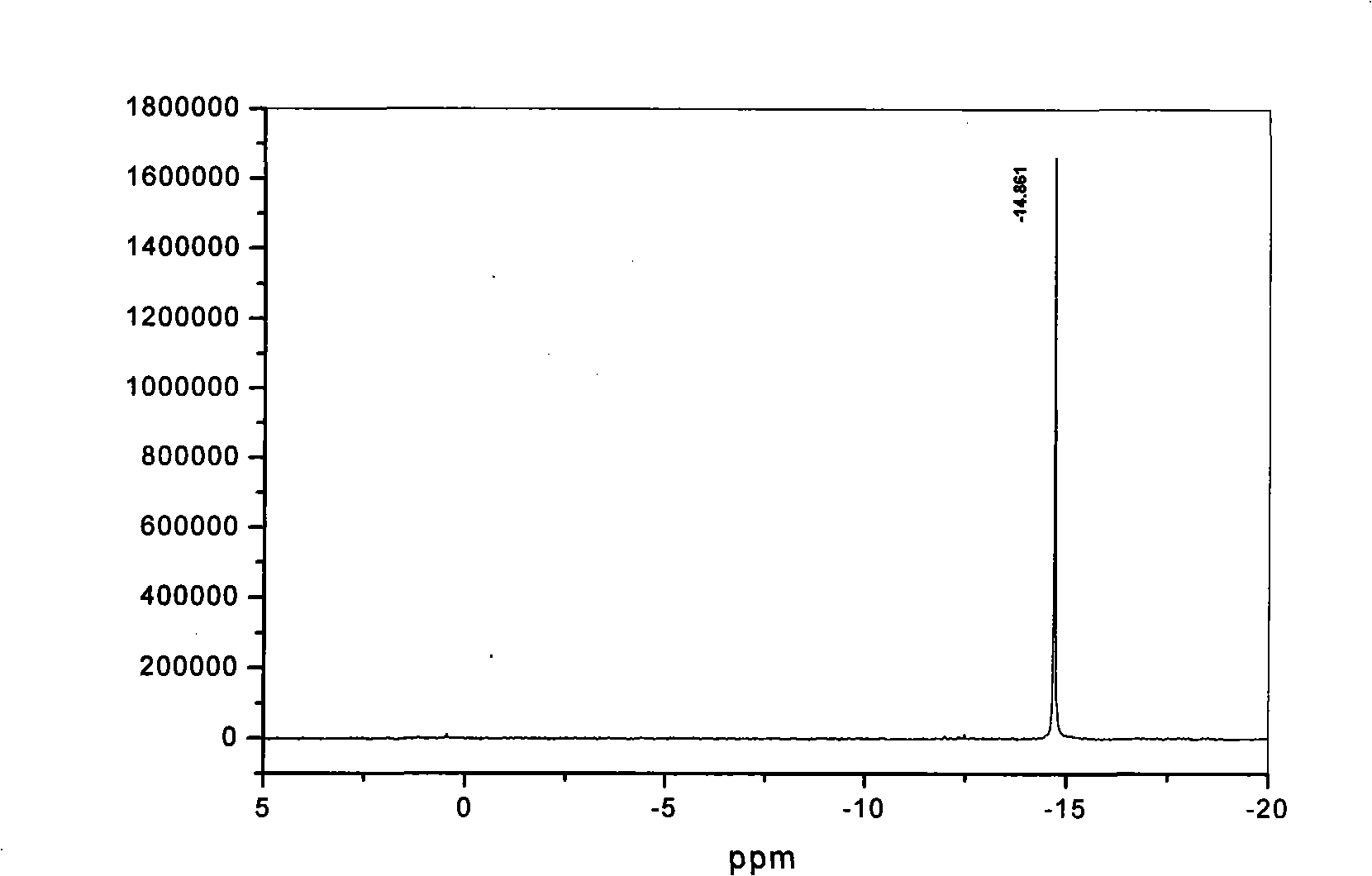

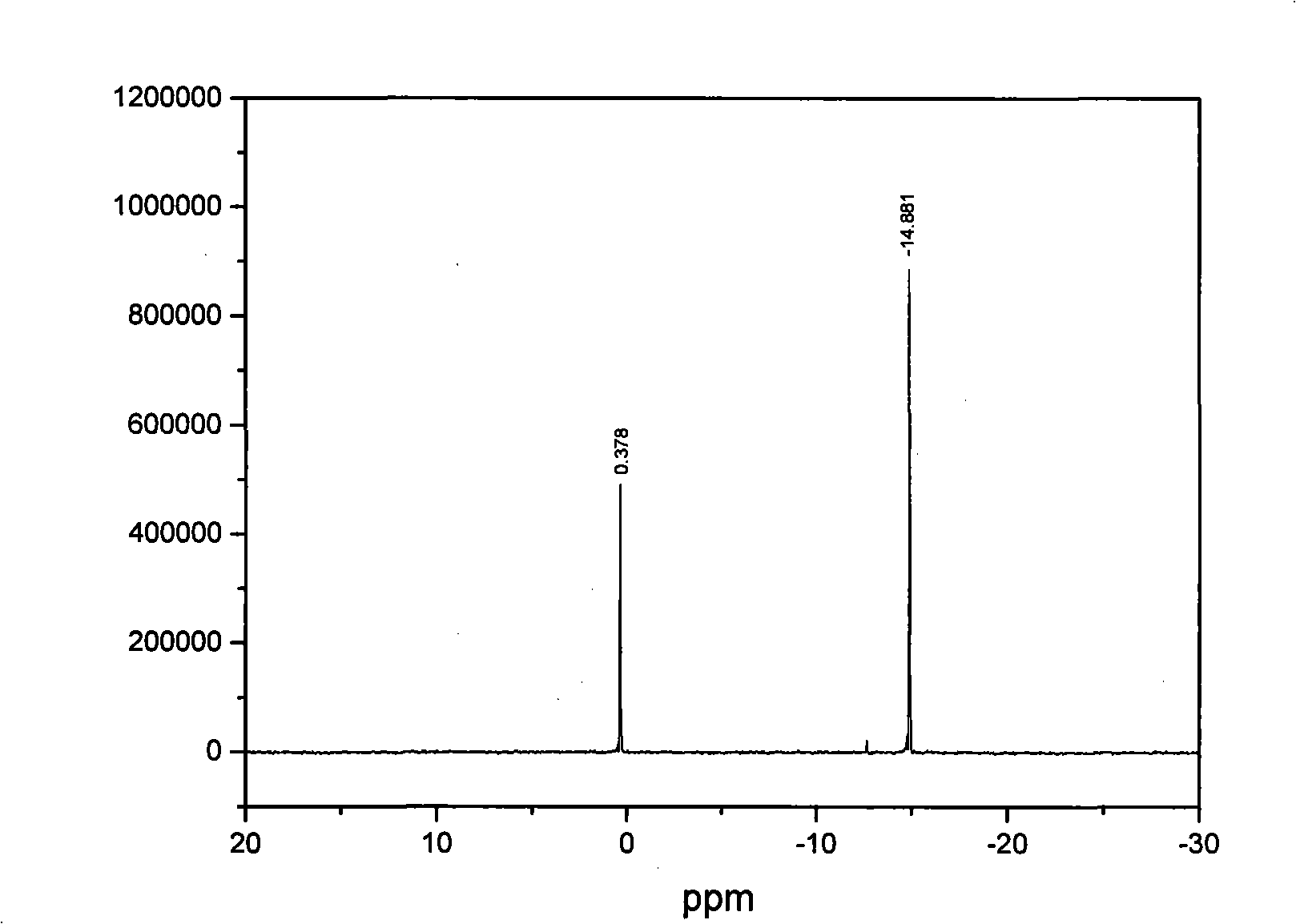

[0037] Sample of phosphotungstic acid 31 P-NMR nuclear magnetic resonance spectrum see figure 1 . figure 1 The peak at the chemical shift -14.861ppm is the peak of th...

Embodiment 2

[0041] Weigh 100 grams of molybdenum trioxide and add it to 600 ml of 17.5% by weight phosphoric acid, heat to boiling, and keep boiling for 4 hours under reflux to obtain a phosphomolybdic acid solution with a concentration of 15% by weight.

[0042] In order to obtain pure phosphomolybdic acid, add 10 grams of concentrated nitric acid (the concentration of nitric acid in the system at this time is about 0.17mol / L) to the phosphomolybdic acid solution at -5°C, cool, precipitate for 12 hours, filter and dry. Obtain 85.6 grams of white yellow phosphomolybdic acid, with H 3 PMo 12 o 40 .6H 2 O meter, the yield is 77%. The results of impurity content analysis are shown in Table 1.

Embodiment 3

[0044] Weigh 100 grams of sodium tungstate, dissolve it in 200ml of water, add 7.5 grams of water glass solution (density 1.375, SiO 2 concentration is 23.5% by weight), heated to boiling, and kept boiling for 4 hours under reflux to obtain a mixed solution of sodium silicotungstate and silicotungstic acid with a concentration of 24% by weight. In order to precipitate silicotungstic acid, add 150 grams of concentrated hydrochloric acid (the concentration of hydrochloric acid in the system is about 5.1mol / L at this time) to the mixed solution of sodium silicotungstate and silicotungstic acid at 80°C, cool and precipitate for 10 hours , filtered and dried. Obtain 57.7 grams of high-purity white silicotungstic acid, with H 3 SiW 12 o 40 .7H 2 O meter, yield is 76.5%. The results of impurity content analysis are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com