High performance aluminum alloy composite foil for heat converter and method of manufacture

A technology for heat exchangers and aluminum alloys, which is applied to aluminum alloys, high-performance aluminum alloy composite foils for heat exchangers and their manufacturing fields, can solve the problems of low strength, unstable performance, low tensile strength and low sag resistance, etc. Achieve excellent tensile strength, excellent hot workability, and the effect of being beneficial to manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

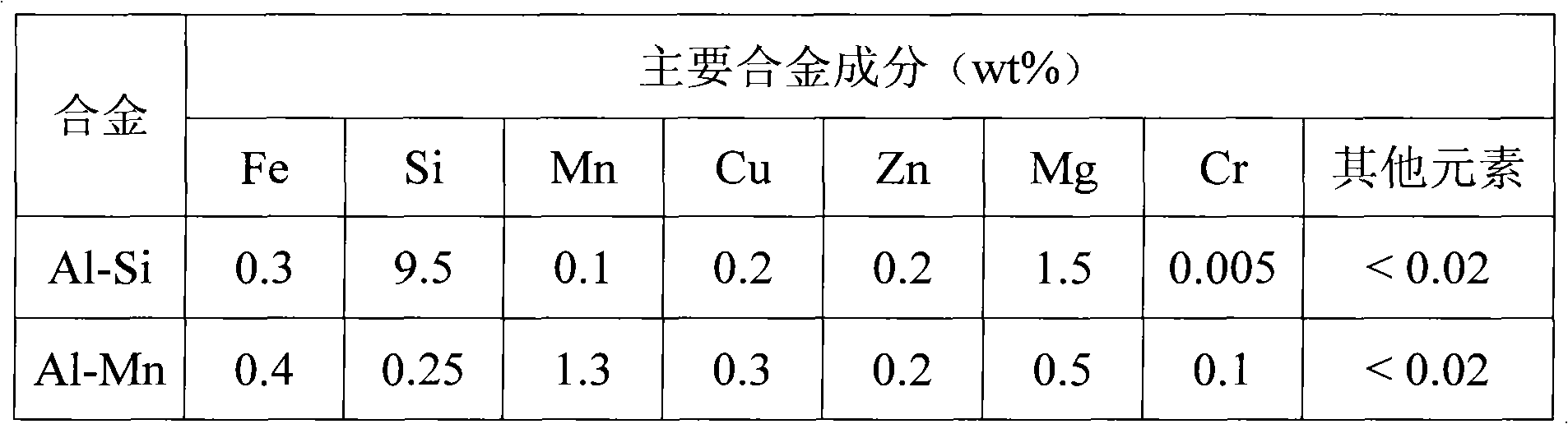

[0039] According to the present invention, one group of alloy compositions is selected for testing, and the chemical composition of the molten alloy is shown in Table 1.

[0040] Table 1

[0041]

[0042] In the process of alloy smelting, each element has different degrees of burning loss. The burning loss rate is Mg: 5-12%, Zn: 5-8%, Mn: 1 to 5%, Cr: 0-3%, Cu :0~3%, the burning loss of each element should be made up during the batching process.

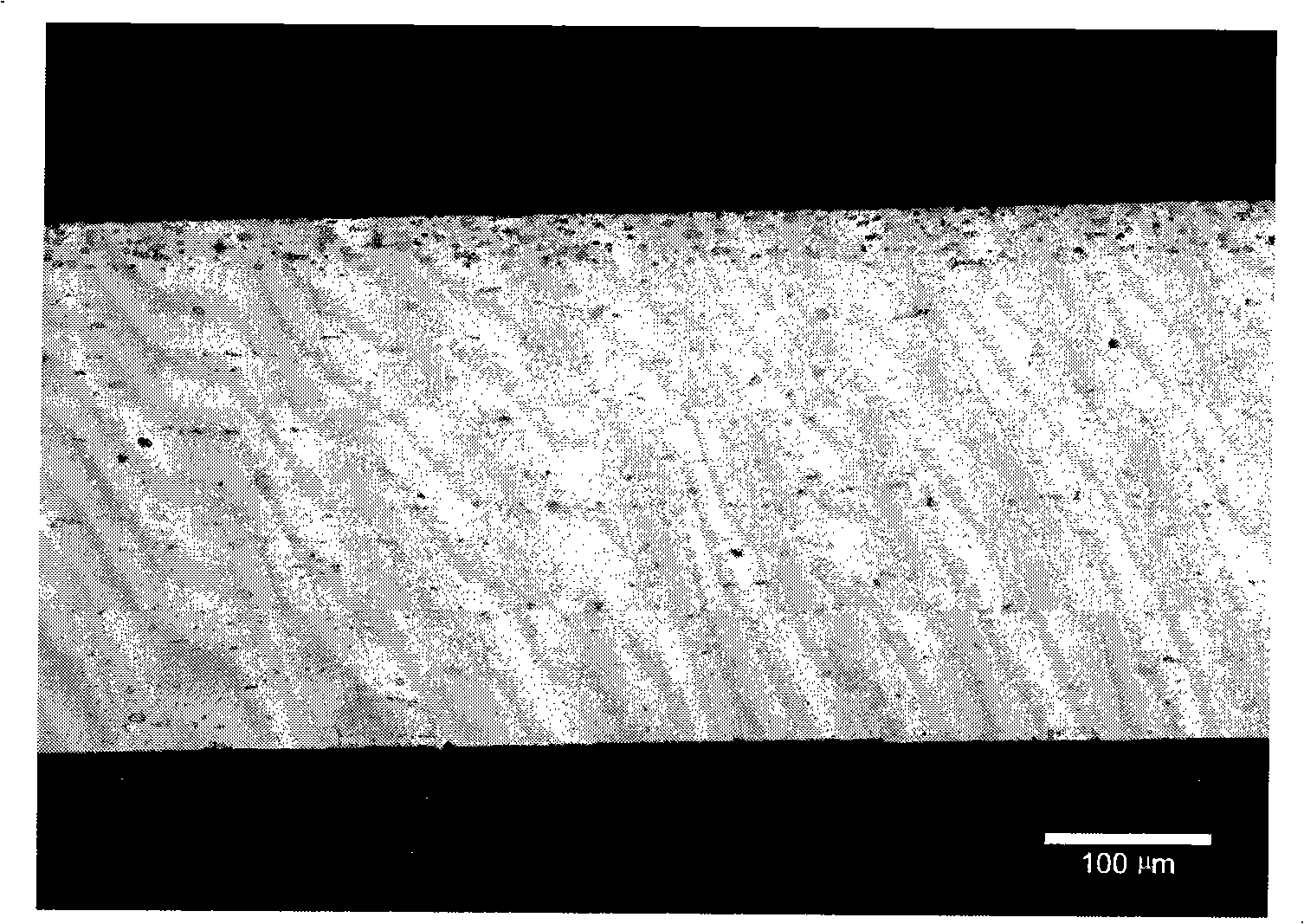

[0043] According to the above implementation method, a single-sided coated aluminum alloy composite foil is obtained, and the metallographic structure is as figure 1 As shown, the final thickness is 0.3mm, and the final cold rolling deformation rates are respectively 40% and 70%. Through finish annealing, products in O state and H24 state are obtained.

[0044] Cut the test piece from the strip obtained above, and measure the tensile strength, yield strength, elongation, and sag resistance. The strength and elongation index are measur...

Embodiment 2

[0049] The alloy composition of this example is the same as in Table 1.

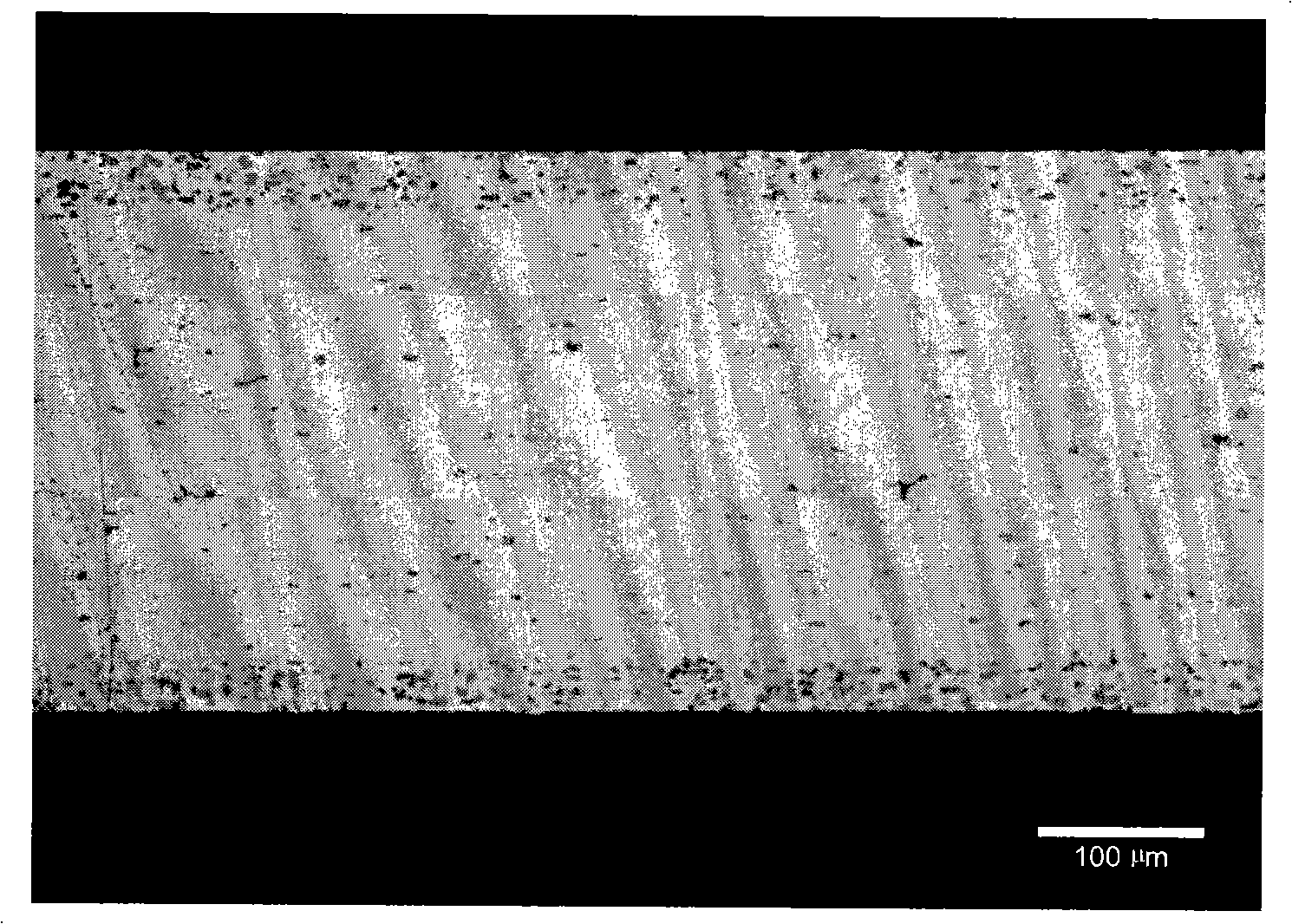

[0050] According to the process parameters selected in Example 1, a double-sided coated aluminum alloy composite foil is obtained, and the metallographic structure is as follows figure 2 As shown, the final thickness is 0.3mm, and the final cold rolling deformation rates are respectively 40% and 70%. Through finish annealing, products in O state and H24 state are obtained.

[0051] According to the detection method of Example 1, the performance results of the aluminum alloy composite foil obtained in this example are recorded in Table 3.

[0052] table 3

[0053]

[0054] The final cold rolling deformation rate of sample 3# is 40%, and the final cold rolling deformation rate of sample 4# is 70%; the test parameters are the same as Table 2.

[0055] It can be shown that this aluminum alloy composite foil has excellent tensile strength, yield strength, elongation and sag resistance, and has good processabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com