Process for preparing high pure rare earth metals by layered distillation method and device

A rare earth metal, high-purity technology, applied in the direction of improving process efficiency and energy efficiency, can solve the problems of low output of resistance furnace, low product purity, and non-reusable condenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

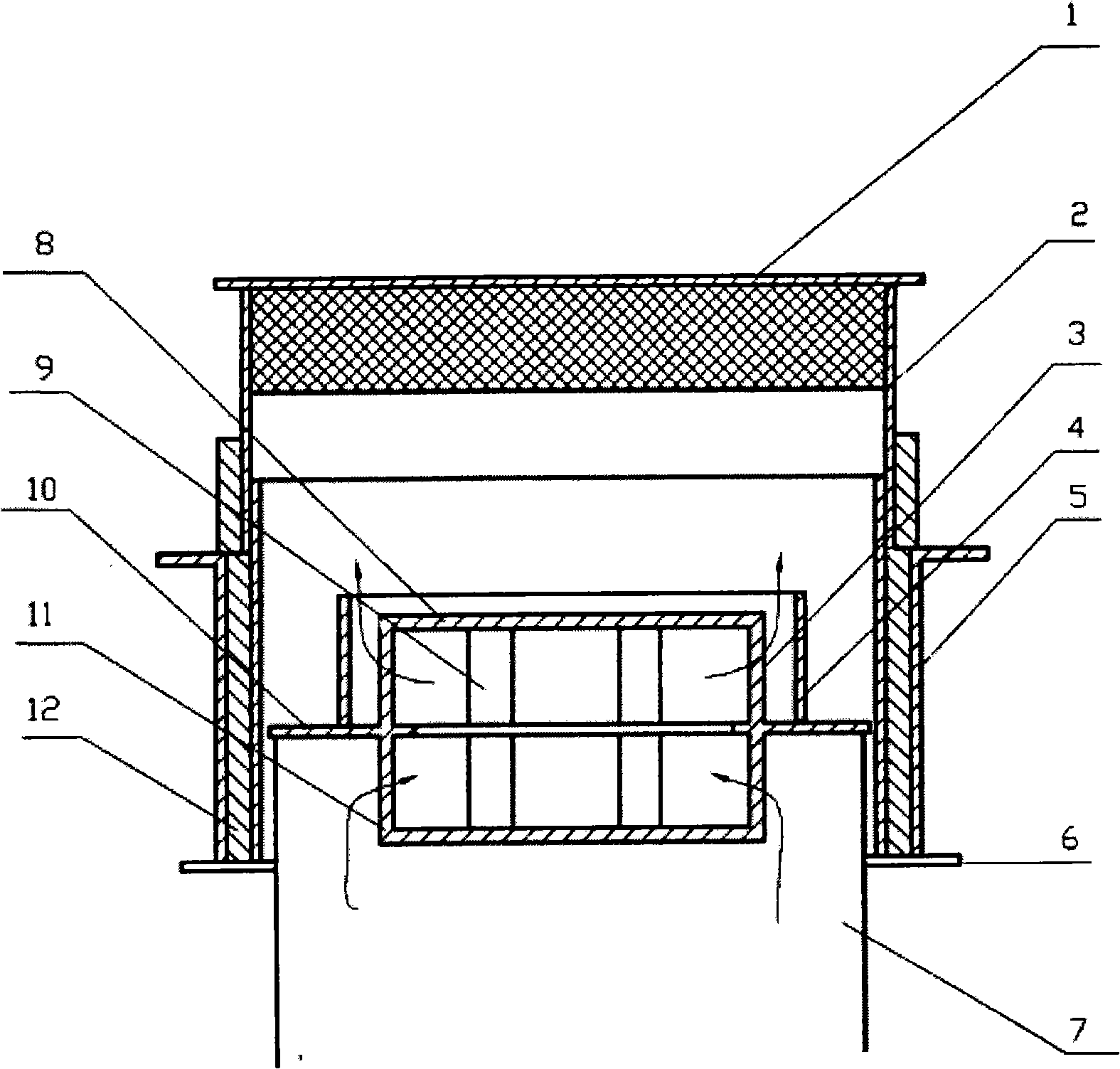

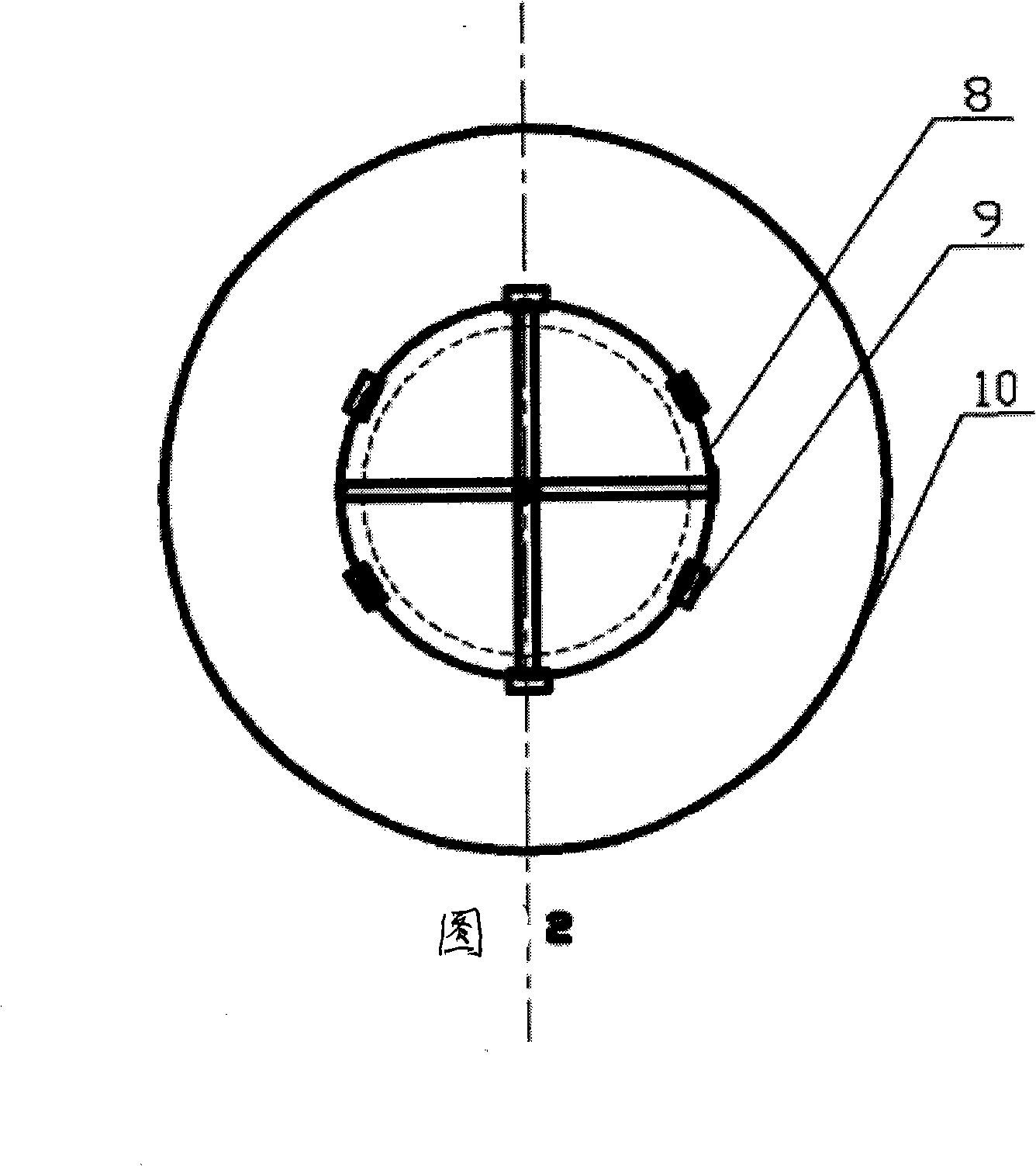

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 adopts 10kg purity to be 99% samarium oxide, 11Kg metal lanthanum as raw material, vacuumize to 10 -1 Below Pa, power on to raise the temperature, power 40kw, heating rate 5°C / min, keep warm at 1200°C for 6 hours, power off and fill with argon for protection, cool down for 3 hours and release from the furnace, the metal yield is 97%, and the metal purity is 99.996%.

[0025] Sm / TREM

Embodiment 2

[0026] Embodiment 2 adopts 10kg purity to be 99% europium oxide, 11Kg metal lanthanum as raw material, vacuumize to 10 -1 Below Pa, power on to raise the temperature, power 40kw, heating rate 10°C / min, keep warm at 1000°C for 6 hours, power off and fill with argon for protection, cool down for 3 hours and release from the furnace, the metal yield is 96%, and the metal purity is 99.998%.

[0027] Eu / TREM

Embodiment 3

[0028] Embodiment 3 adopts thulium oxide, 22Kg metal lanthanum as raw material that 20kg purity is 99%, vacuumizes to 10 -1 Below Pa, power on to raise the temperature, power 40kw, heating rate 11°C / min, keep warm at 1250°C for 6 hours, power off and fill with argon for protection, cool down for 3 hours and release from the furnace, the metal yield is 96%, and the metal purity is 99.99%.

[0029] Tm / TREM

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com