Method for preparing sewage purification treatment material and device

A technology for sewage purification and preparation device, which is applied in adsorption water/sewage treatment, chemical instruments and methods, and other chemical processes, etc. It can solve the problems of blocking water vapor channels, inability to activate, and aggravating air pollution, so as to reduce preparation costs. , to achieve controllability, improve the effect of activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

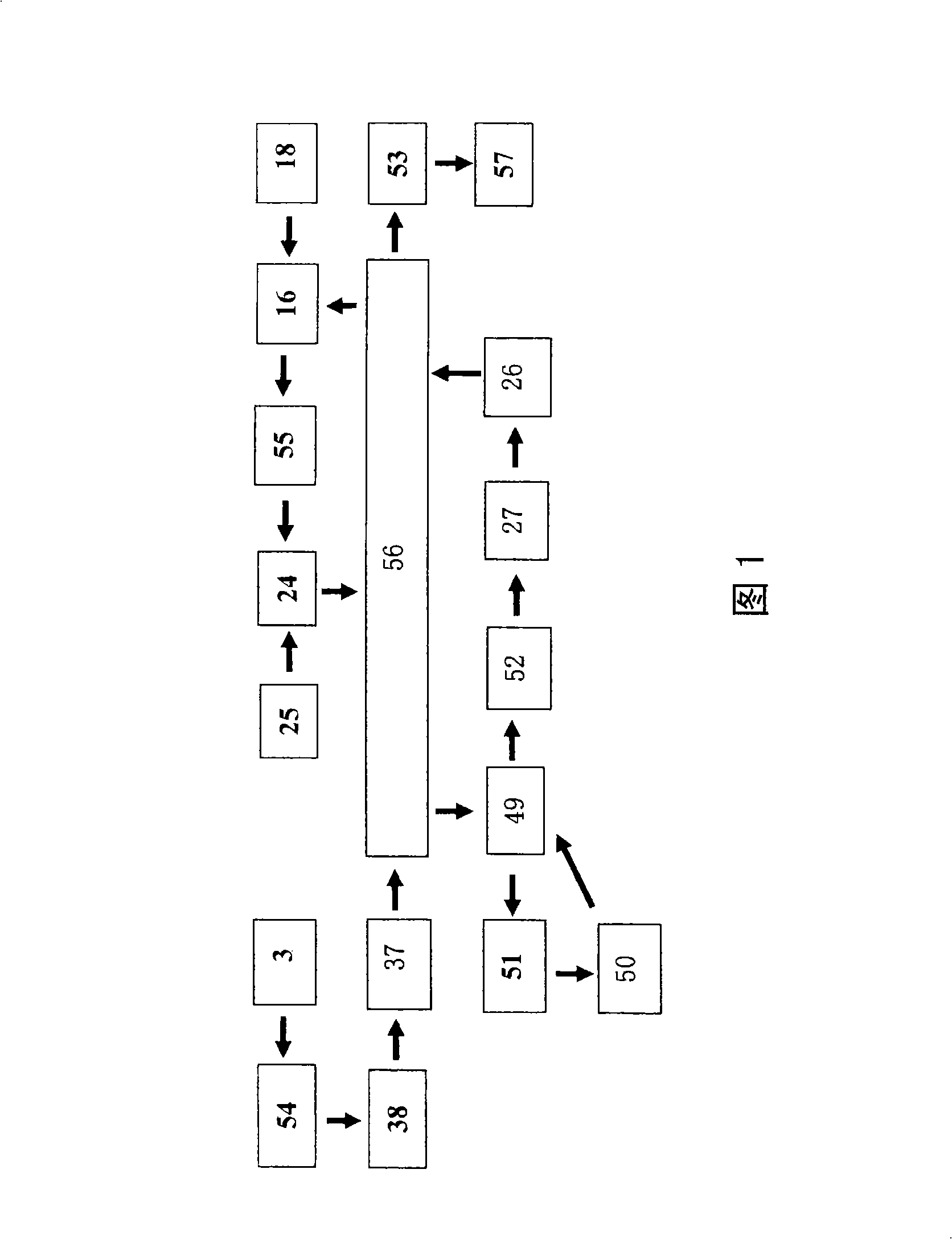

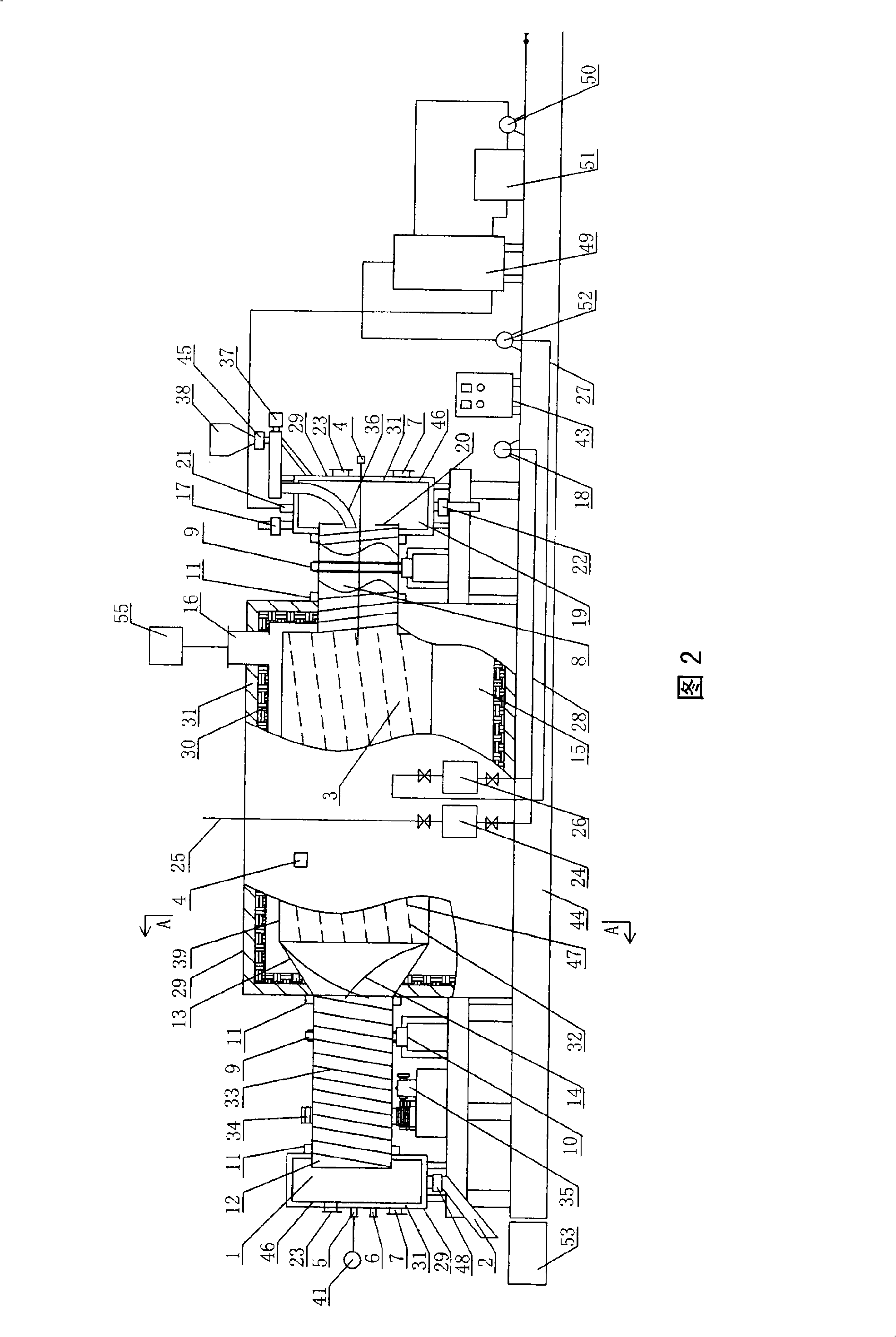

[0037] The working principle process of the preparation of sewage purification treatment materials adopted in the present invention is shown in Figure 1, combined with Figure 2.

[0038] The raw material is coke powder 3 produced in the screening process of coke, blue coke, and semi-coke produced by coking enterprises, with a particle size≤5mm, sent to the feed bin 38 by the conveying equipment 54, and then sent to the silo of the present invention by the screw conveyor 37. The drum 39 of the preparation device 56 is heated inside, and the heat source for heating is coal gas 25 and the water gas 27 produced during the operation of the preparation device 56; coke powder 3 is added to the preparation device 56, and steam 40 is input when heated to 550-650°C, and the input steam The volume is 0.8~1.5m 3 3 per ton of coke powder; after the temperature continues to rise to 850-950°C, heat for 60-120 minutes, then turn off the burner to stop heating. When the temperature drops to 4...

Embodiment 1

[0061] The length of present embodiment cylinder 39 is 6 meters, and diameter is 1 meter; The length of feed pipe 8 is 0.5 meter, and the length of discharge pipe 12 is 1 meter, and the diameter of feed pipe 8, discharge pipe 12 is 0.5 meter . The design rotating speed of drum 39 is 4~6r / min, and drum 39 can change the direction of rotation. The distance between the cylinder 39 outer wall and the heating chamber 15 side inner wall is 200mm, the distance between the cylinder 39 outer wall and the heating chamber 15 top inner wall is 200mm, and the distance between the cylinder 39 outer wall and the heating chamber 15 bottom inner wall is 600mm.

[0062] The inner wall of the drum 39 is equipped with multiple rows of turning plates 32 and material guide plates 47, the distance between every two rows of material turning plates 32 and material guide plates 47 is 300mm, each row is composed of multiple turning plates 32 and material guide plates 47 The composition is installed at ...

Embodiment 2

[0066] The cylinder 39 of this embodiment has a length of 10 meters and a diameter of 1.5 meters; the length of the feed pipe 8 is 1 meter, the length of the discharge pipe 12 is 1.5 meters, and the diameters of the feed pipe 8 and the discharge pipe 12 are 0.7 meters. The design rotating speed of drum 39 is 4~6r / min. The distance between the cylinder 39 outer wall and the heating chamber 15 side inner wall is 300mm, the distance between the cylinder 39 outer wall and the heating chamber 15 top inner wall is 300mm, and the distance between the cylinder 39 outer wall and the heating chamber 15 bottom inner wall is 650mm.

[0067]The inner wall of the drum 39 is equipped with multiple rows of material turning plates 32 and material guide plates 47, the distance between every two rows of material turning plates 32 and material guide plates 47 is 500 mm, each row is composed of multiple material turning plates 32 and material guide plates 47 The composition is installed at interva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com