Method for measuring purity of trinexapac-ethyl standard substance

A standard substance and determination method technology, which is applied in the field of purity determination of trinexapac-ethyl agrotoxic chemical standard substances, can solve the problems of increasing the viscosity of the mobile phase, affecting the purity analysis results, increasing the system analysis pressure, etc., and achieving peak presentation properties. Good, repeatable and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Experimental equipment

[0038] Agilent1100 high performance liquid chromatography was selected, equipped with vacuum online degasser, quaternary gradient pump, 100 μL autosampler, multi-wavelength ultraviolet detector, column oven, and Agilent1100 chromatographic workstation.

[0039] 2. Test conditions

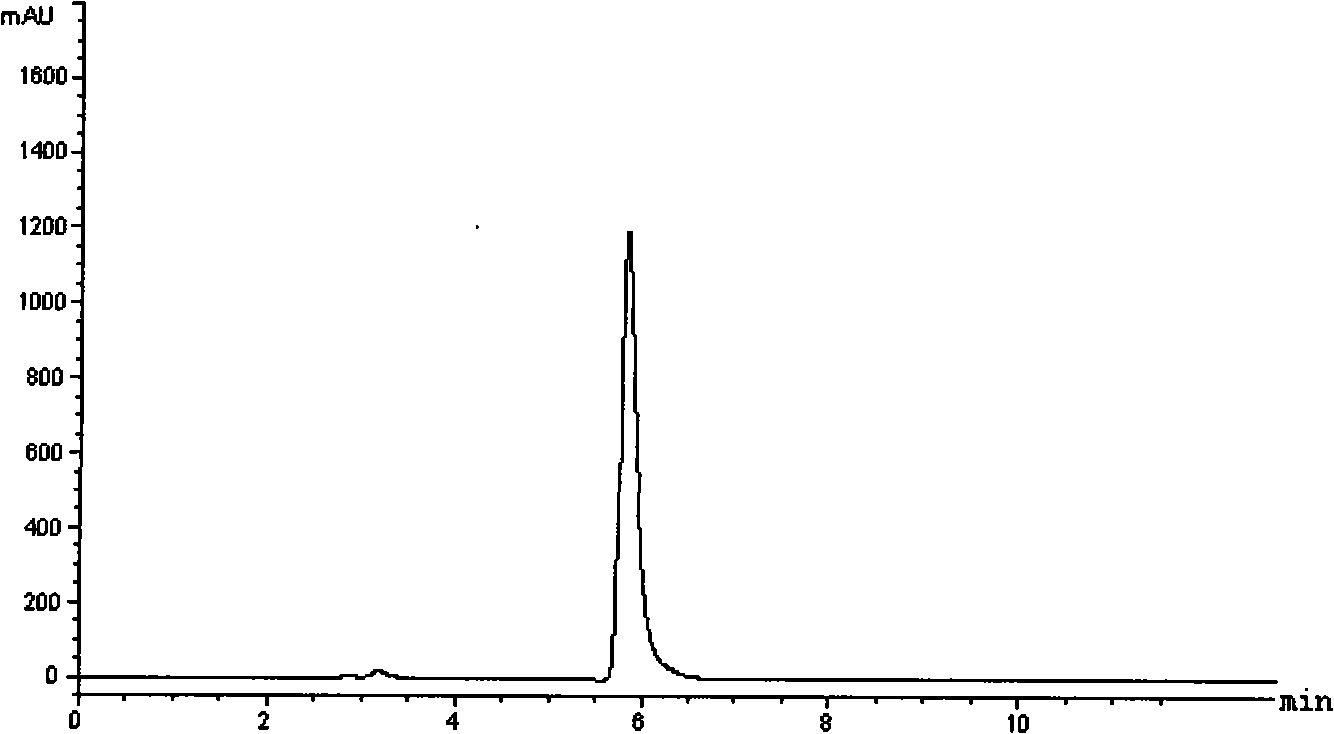

[0040] Chromatographic column: zorbax SB C18; column temperature 30°C; flow rate of mobile phase: 0.5mL / min; detection wavelength: 275nm; phase A of the mobile phase is formic acid: water = 0.2:100 (V / V), phase B is chromatography Pure grade acetonitrile, A phase: B phase=60:40 (V / V); Utilize mobile phase to prepare the solution of trinexapac-ethyl standard substance, make its absorption value on the ultraviolet detector 1200mAU; Injection volume: 10 μ L; After the instrument was stabilized, inject the sample, record the peak area, and calculate the purity of the trinexapac-ethyl standard substance by the area normalization method.

[0041] The peak area data of ...

Embodiment 2

[0045] 1. Experimental equipment

[0046] Described with embodiment 1.

[0047] 2. Test conditions

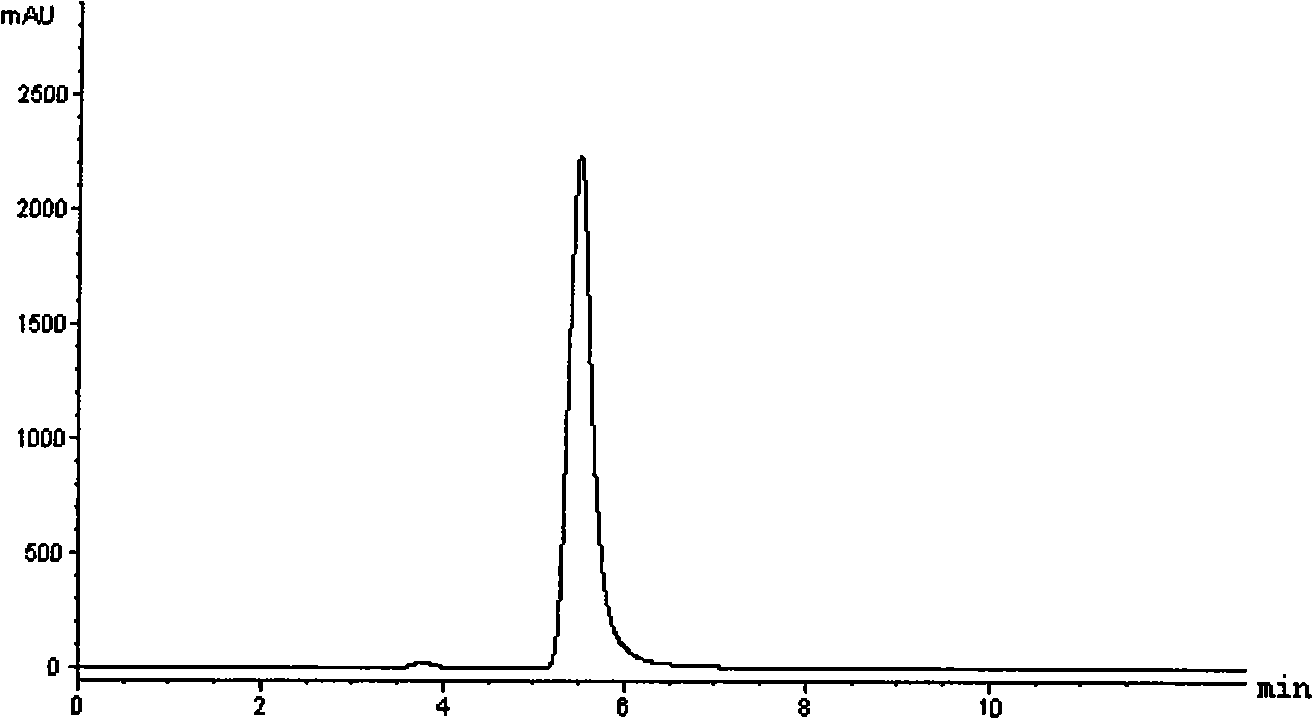

[0048] The flow rate of the mobile phase: 0.2mL / min; the A phase of the mobile phase is formic acid: water=0.05:100 (V / V), and the B phase is chromatographically pure grade methanol, A phase: B phase=80:20 (V / V ); Utilize mobile phase to prepare the solution of trinexapac-ethyl standard substance, make its absorption value on the ultraviolet detector be 2500mAU; Injection volume: 5 μ L; All the other conditions are as described in embodiment 1.

[0049] The peak area data of this embodiment are shown in Table 2, and the purity result calculated by the area normalization method is 98.7%, and its typical chromatogram is shown in figure 2 shown.

[0050] The peak area data of table 2 embodiment 2

[0051]

Embodiment 3

[0053] 1. Experimental equipment

[0054] Described with embodiment 1.

[0055] 2. Test conditions

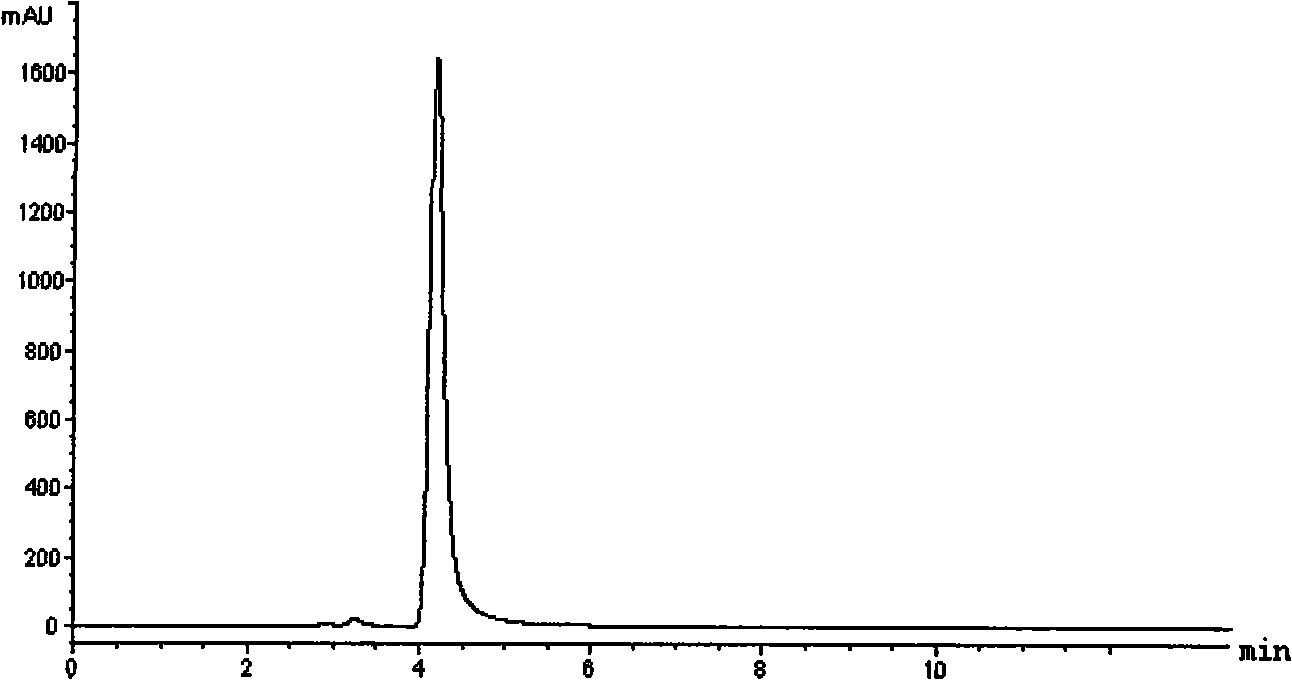

[0056] The flow rate of the mobile phase: 0.8mL / min; the A phase of the mobile phase is formic acid: water=0.1:100 (V / V), and the B phase is chromatographically pure grade acetonitrile, A phase: B phase=20:80 (V / V ); Utilize mobile phase to prepare the solution of trinexapac-ethyl standard substance, make its absorption value on the ultraviolet detector 1600mAU; Injection volume: 50 μ L; All the other conditions are as described in embodiment 1.

[0057] The peak area data of this embodiment are shown in Table 3, and the purity result calculated by the area normalization method is 98.8%, and its typical chromatogram is shown in image 3 shown.

[0058] The peak area data of table 3 embodiment 3

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com