Melting strip electrode automatic condensed electric arc re-melt deposit welding method and device thereof

A melting zone and arc technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of unstable bonding strength and performance, slag inclusion at the bonding interface, and inability to guarantee welding rate, etc., achieving low cost, The effect of high deposition welding strength and stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

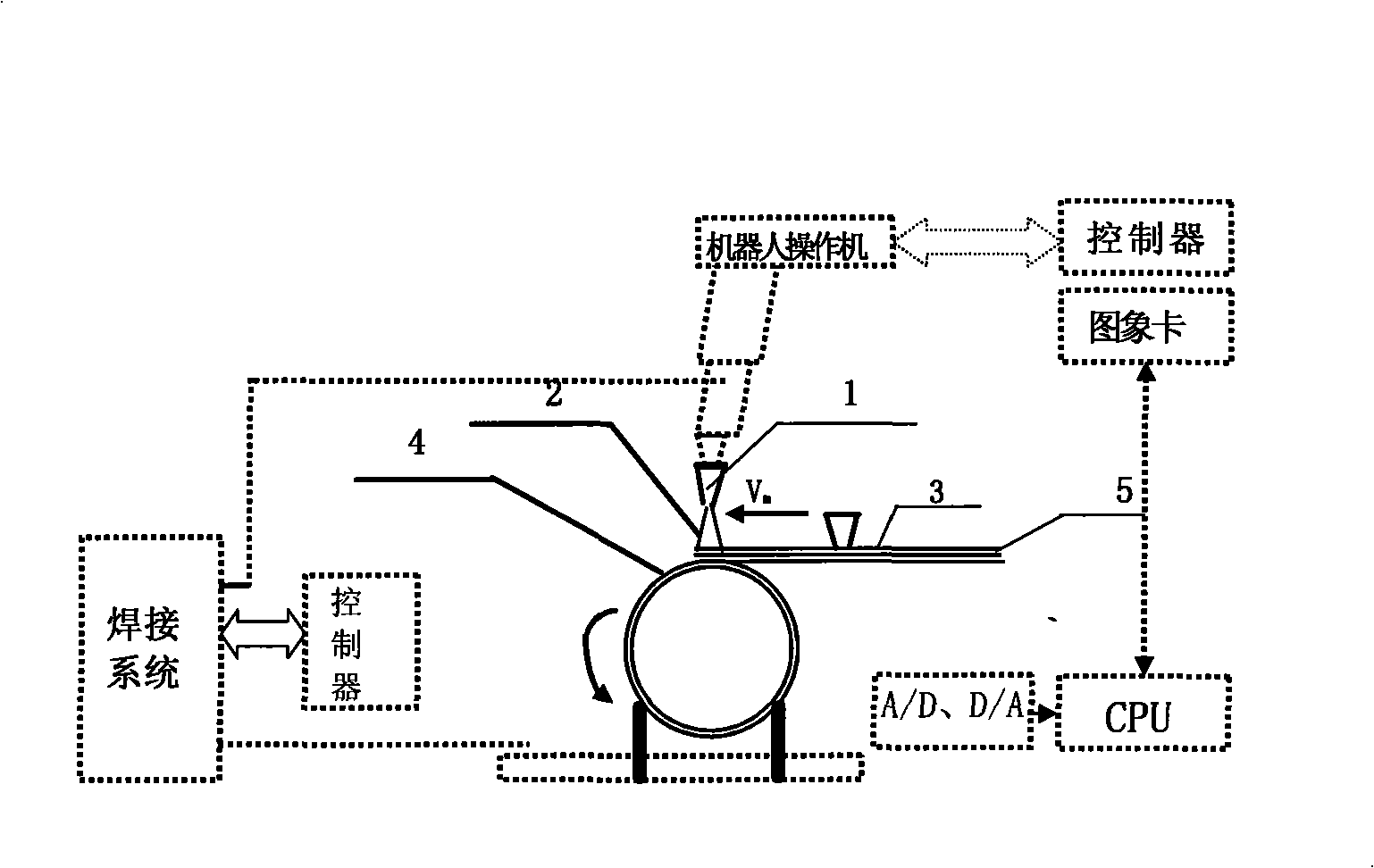

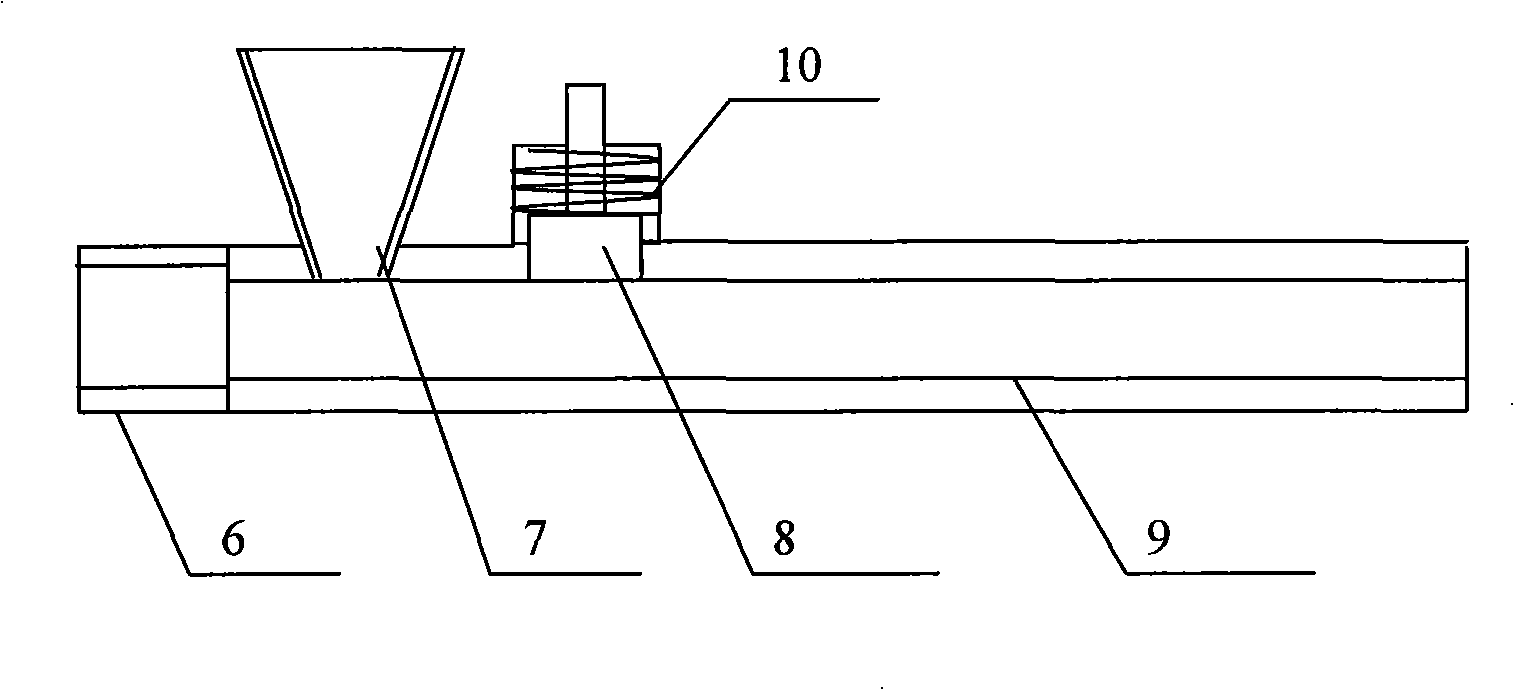

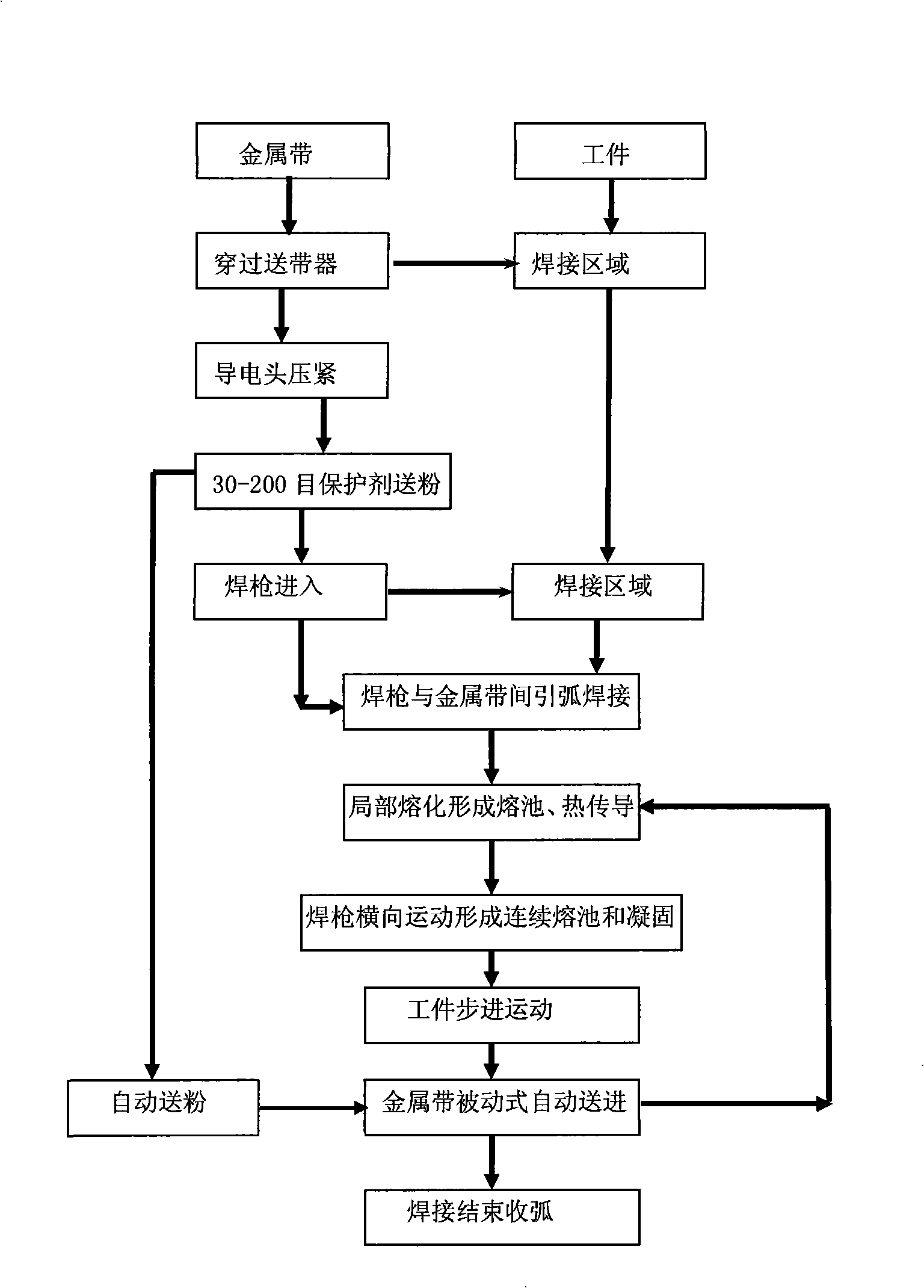

[0022] Example 1: Combining Figures 1 to 3, taking the 155mm diameter 58SiMn cylindrical body (cylinder) surface welding brass layer as an example. Pass the 5cm×5mm96 brass metal strip through the specially designed rectangular strip feeding tube 9 of the strip feeder 3 to the surface of the tubular (155mm outer diameter) steel substrate to be welded. The inner hole of the rectangular strip feeding tube 9 is 55mm wide and 6mm high , there is a protective agent automatic filling device powder feeder 7 (filling funnel) above the rectangular feeding pipe 9, the size of the leak hole at the bottom of the funnel is 20-35mm×20-30mm, the protective agent mesh is 60-120 mesh, and the rectangular feeding pipe 9. The 1mm difference between the thickness of the inner rectangular hole and the thickness of the brass metal strip determines the amount of protective agent delivered. With the automatic feeding of the brass metal strip, the protective agent is evenly and automatically spread o...

Embodiment 2

[0023] Example 2: Combining Figures 1 to 3 , taking the stainless steel layer deposited on the surface of a 170mm diameter 45 cylindrical body (cylinder) as an example. Pass the 4cm×4mm 1Cr18Ni9Ti stainless steel strip through the specially designed rectangular strip feeding tube 9 of the strip feeder to the part to be welded on the surface of the tubular (170mm outer diameter) steel substrate. There is a protective agent automatic filling device powder feeder 7 (filling funnel) above the rectangular tape feeding pipe 9, the size of the hole at the bottom of the funnel is 20-30mm×20-25mm, the mesh number of the protective agent is 40-80 mesh, and the rectangular tape feeding pipe 9 The 1mm difference between the thickness of the inner rectangular hole and the thickness of the stainless steel strip determines the amount of protective agent delivered. With the automatic feeding of the stainless steel strip, the protective agent spreads evenly and automatically on the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com