Amorphous tungsten-doped tin dioxide transparent conductive oxide thin film and preparation method thereof

An oxide thin film, transparent and conductive technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of low doping efficiency, etc., achieve high carrier mobility, stable performance, and high film deposition rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

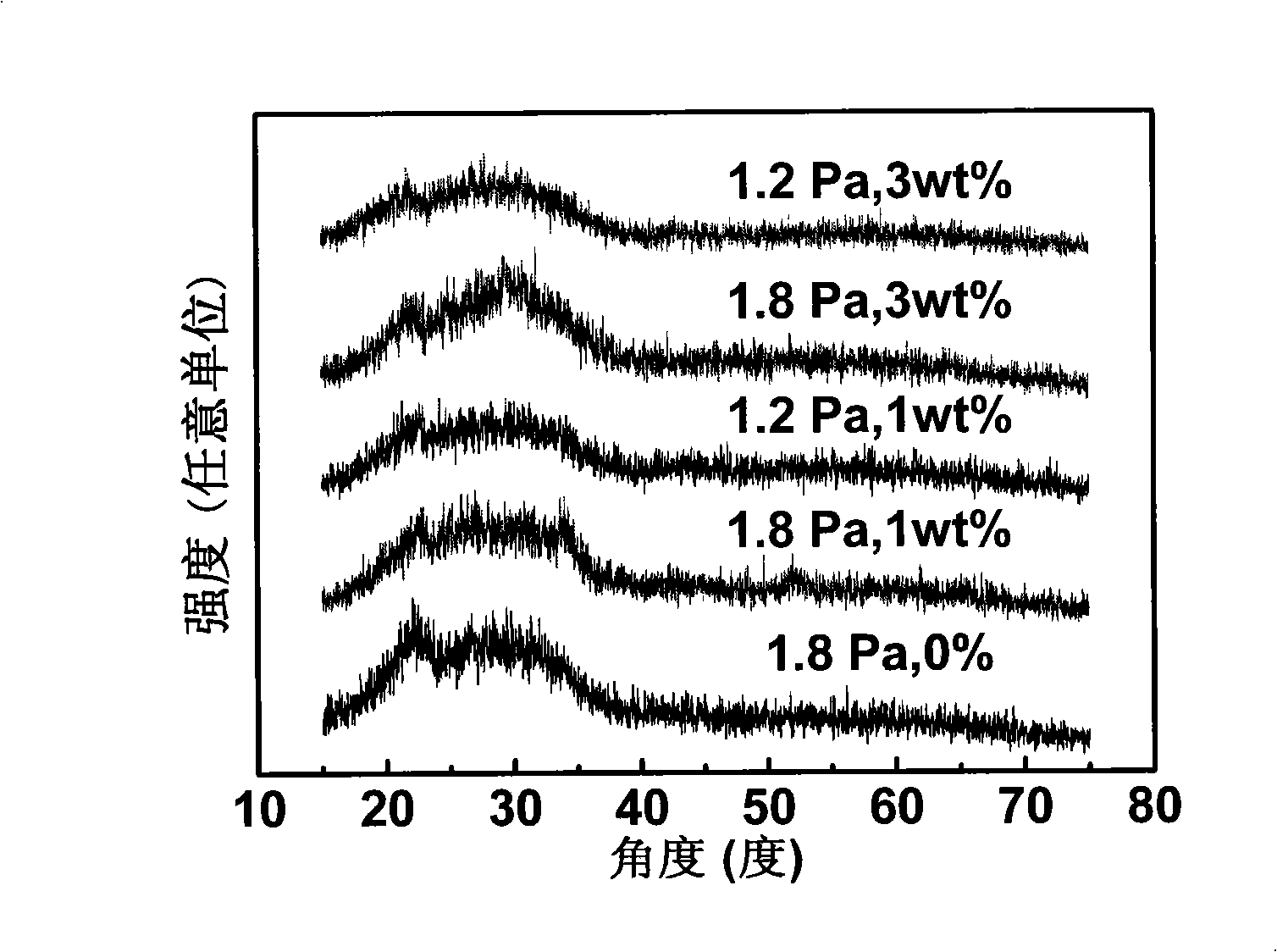

[0019] Example 1, preparation of tungsten-doped tin dioxide ceramic target: grind and mix the mixed powder of chemically pure tin dioxide and tungsten evenly, sinter in air at 800°C for 12 hours, grind and mix evenly after cooling, and then grind and mix evenly at 13MPa Keep it under pressure for 10 minutes to form a target with a diameter of 25 mm and a thickness of 3 mm, and sinter at 850° C. for 12 hours to form a target. The substrate is an ordinary glass slide, which has been cleaned by pure water and alcohol ultrasonic waves for 15 minutes each.

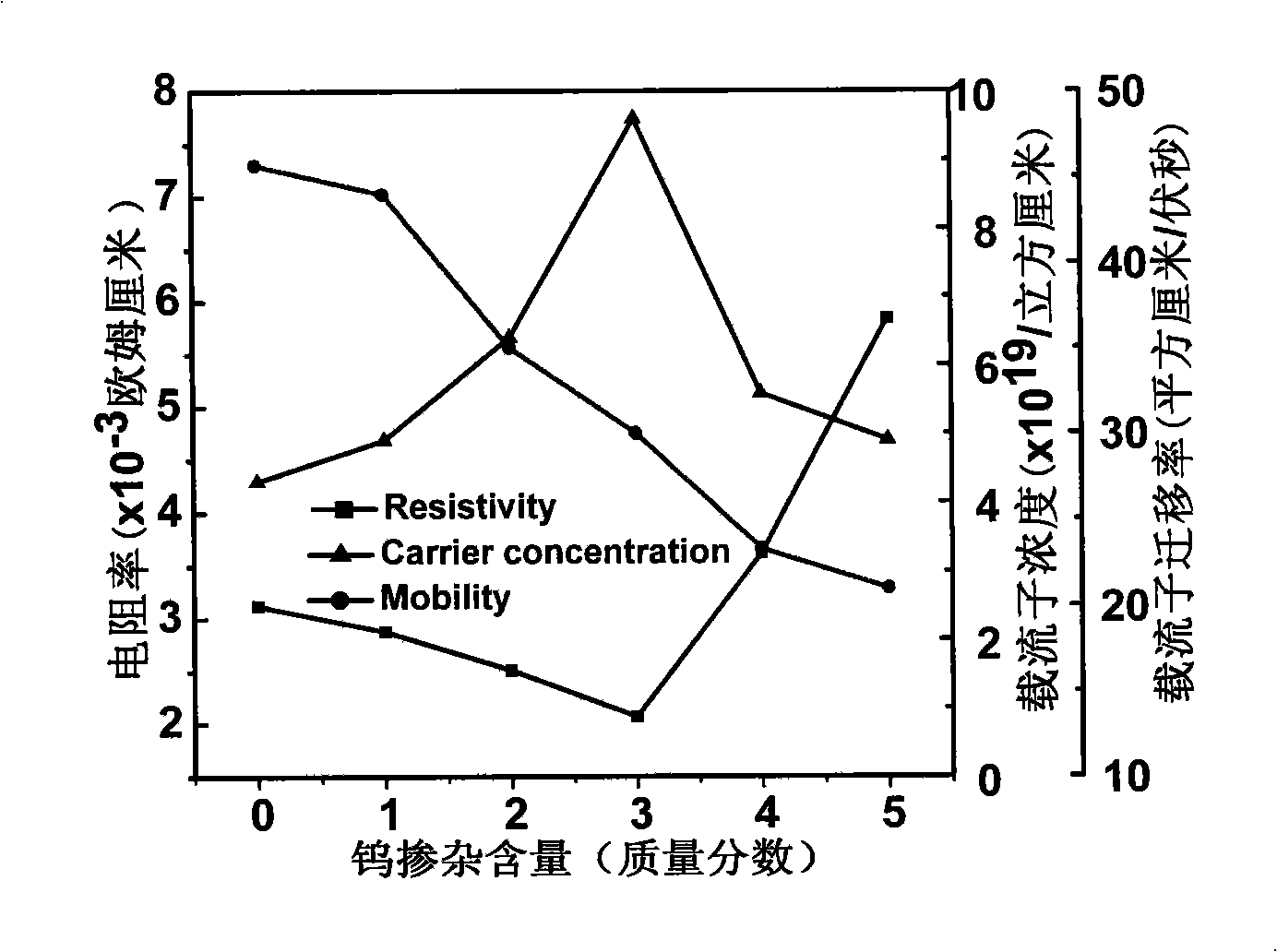

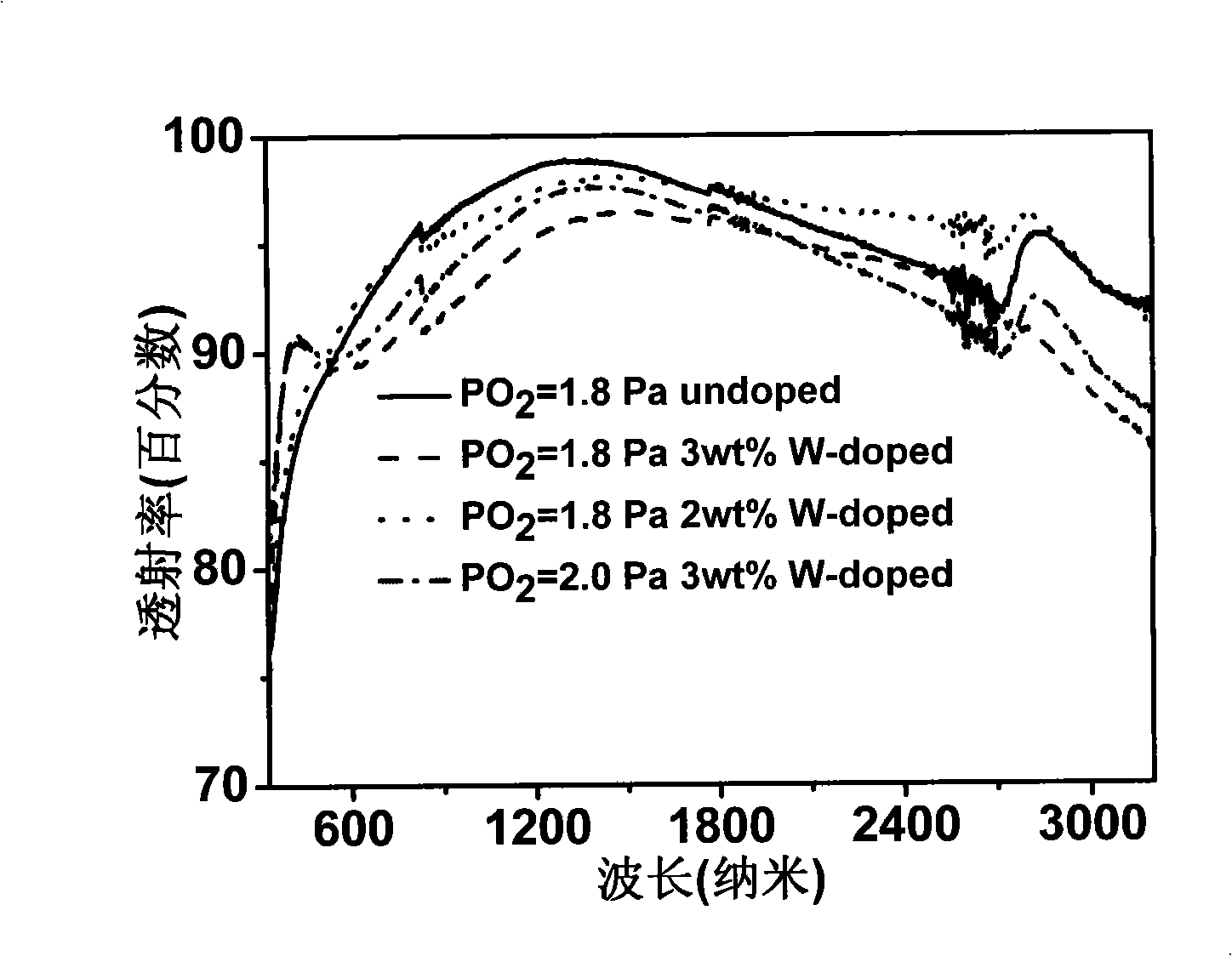

[0020] The tungsten doping content is 1 wt%. Before film deposition, the deposition chamber is evacuated to below 6.5×10 -3 Pa, then the O through the variable air pilot valve 2 and Ar gas into the vacuum chamber. The working pressure in the deposition chamber is 3.0Pa, the temperature of the ordinary glass substrate is 400°C, the oxygen partial pressure is 1.8Pa, the working current is 3.6mA, the working voltage is -16kV, a...

Embodiment 2

[0021] Example 2, preparation of tungsten-doped tin dioxide ceramic target: Grind and mix the mixed powder of chemically pure tin dioxide and tungsten evenly, sinter in air at 800°C for 12 hours, grind and mix evenly after cooling, and then grind and mix evenly at 13MPa Keep it under pressure for 10 minutes to form a target with a diameter of 25 mm and a thickness of 3 mm, and sinter at 850° C. for 12 hours to form a target. The substrates are ordinary glass slides and quartz glass, which are cleaned by pure water and alcohol ultrasonic waves for 15 minutes each.

[0022] The tungsten doping content is 3 wt%. Before film deposition, the deposition chamber is evacuated to below 6.5×10 -3 Pa, then the O through the variable air pilot valve 2 and Ar gas into the vacuum chamber. The working pressure in the deposition chamber is 3.0Pa, the ordinary glass substrate temperature is 400°C, the oxygen partial pressure is 1.2Pa, the working current is 3.6mA, the working voltage is -16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com