Method for manufacturing reactor coil wire lead

A manufacturing method and reactor technology, applied in coil manufacturing, transformer/inductor coil/winding/connection, etc., can solve problems such as chemical corrosion and temperature difficulty, and achieve high connection strength, low cost and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A reactor coil lead wire can be manufactured according to the following steps:

[0015] 1) Take a strip-shaped sheet-shaped copper bar for high-temperature annealing treatment. The length of the copper bar is required to be 10cm, the width is 2cm, the thickness is 1.5mm, the annealing temperature is 400°C, and the HB value after annealing is between 45-55;

[0016] 2) Take the aluminum foil with the same shape as the copper bar, the thickness of the aluminum foil is 0.1mm, and the purity is above 99.5%; for the surface treatment of the copper bar and aluminum foil: during the treatment, the single side of the copper bar and the aluminum foil is sanded to remove the oxide layer Treatment to remove the surface oxide layer;

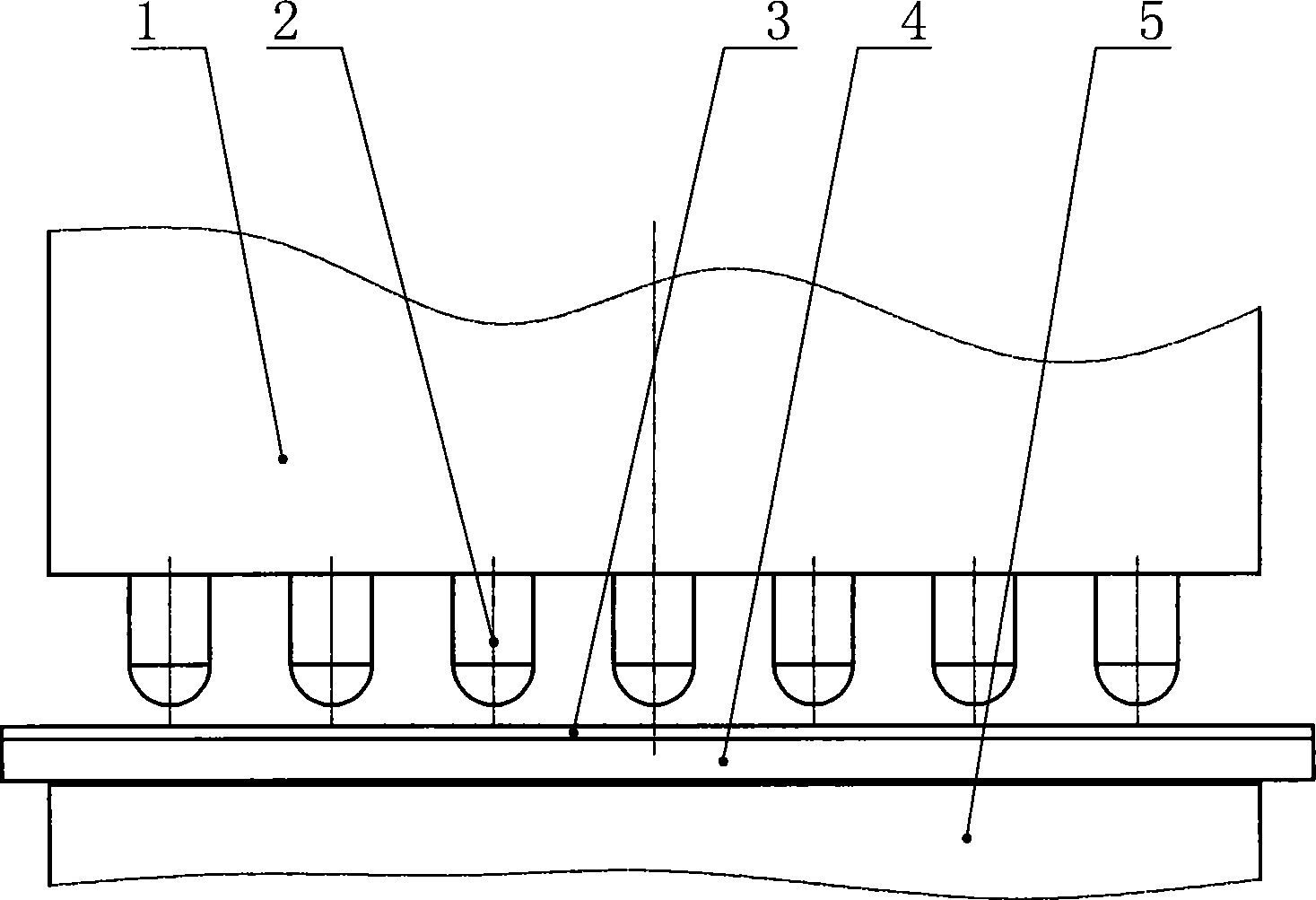

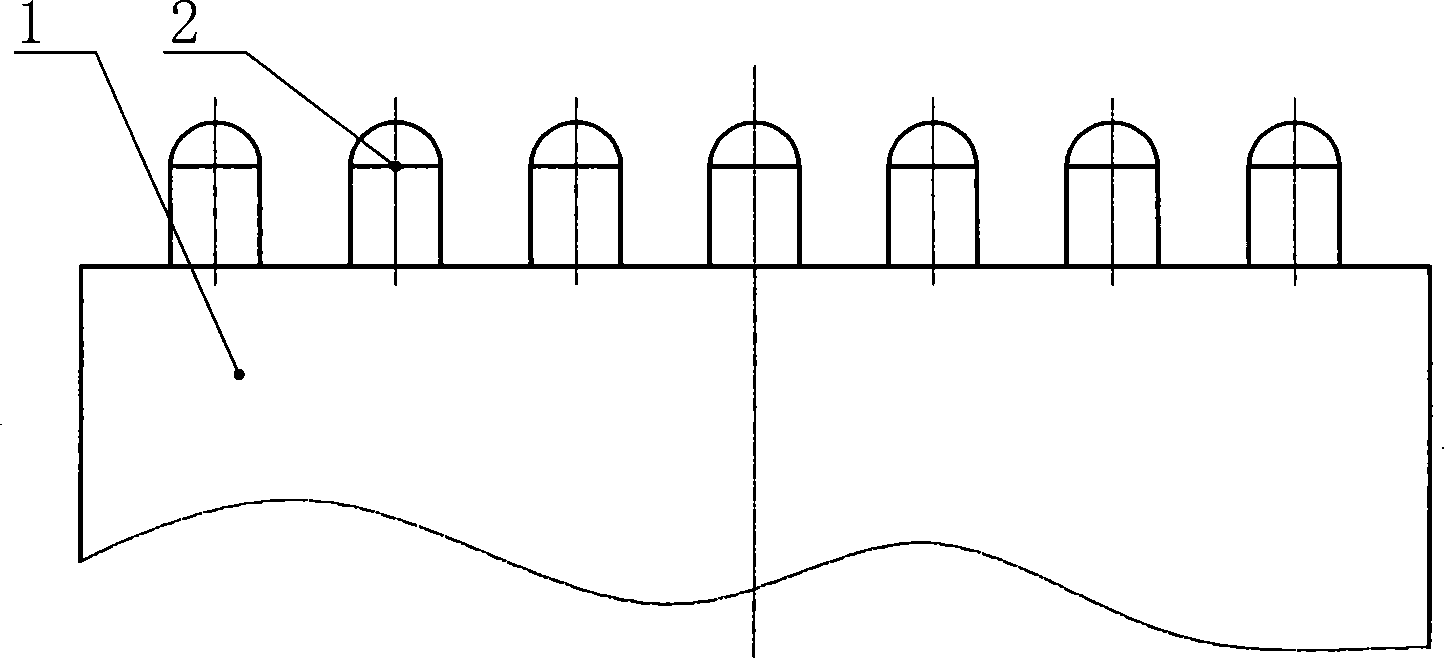

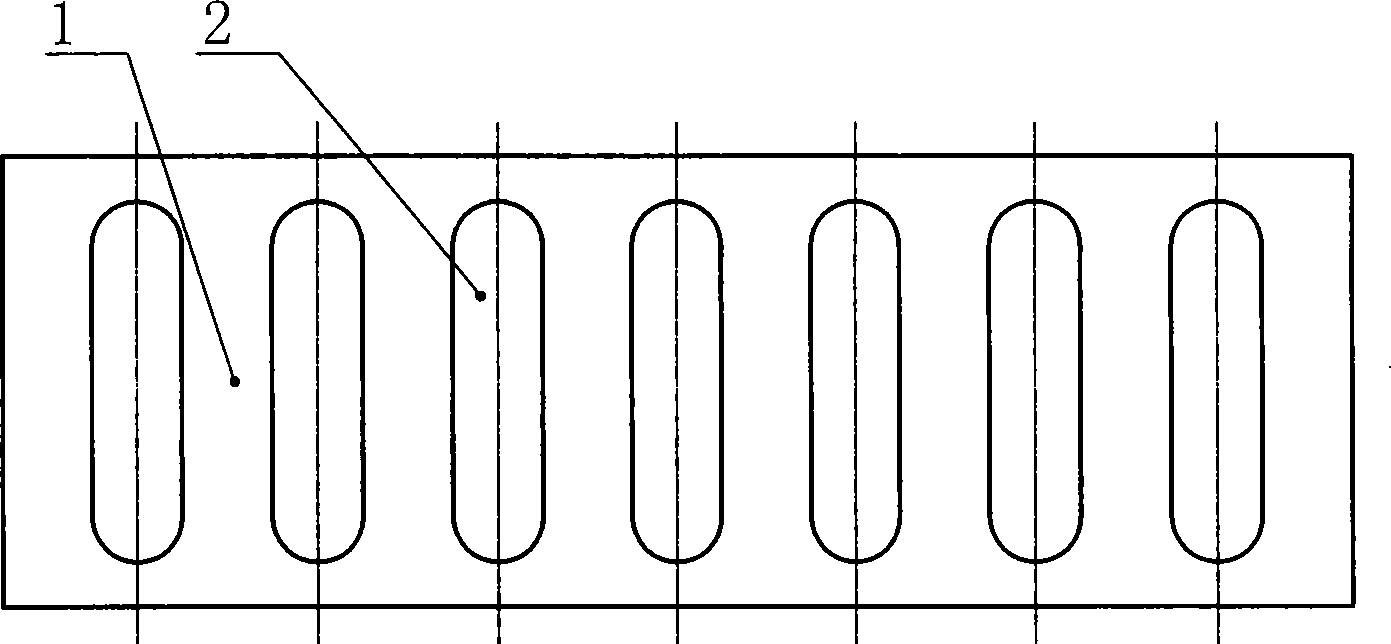

[0017] 3) if figure 1 As shown, the copper bar 4 and the aluminum foil 3 are cold-pressed: within 1 hour after the surface treatment, the mold is used for crimping on the press. The mold is composed of an upper mold 1 and a lower mold 5, wherein the ...

Embodiment 2

[0019] Yet another reactor coil lead wire can be manufactured according to the following steps:

[0020] 1) High-temperature annealing treatment for strip-shaped copper bars: Take a copper bar with a length of 30cm, a width of 5cm, and a thickness of 6mm for annealing treatment. The annealing temperature is 600°C, and the HB value after annealing is between 45-55. between;

[0021] 2) Copper bar and aluminum foil surface treatment: take aluminum foil with the same shape as the copper bar, the thickness of the aluminum foil is 3mm, and the purity is above 99.5%; the copper bar and one side of the aluminum foil are deoxidized and sanded to remove surface oxidation layer;

[0022] 3) Cold crimping of copper bars and aluminum foil: within 1 hour after surface treatment, crimping is carried out on a press using a mold. The mold is composed of an upper mold and a lower mold, wherein the upper mold has several elongated ridge-like protrusions , the ridge-like protrusions are arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com