Method for improving illumination efficiency of organic electroluminescent device, and corresponding device thereof

A technology of light extraction efficiency and electroluminescence, applied in electroluminescence light source, electric solid device, electric light source, etc., can solve the problems of unutilized light energy and only light extraction efficiency of devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

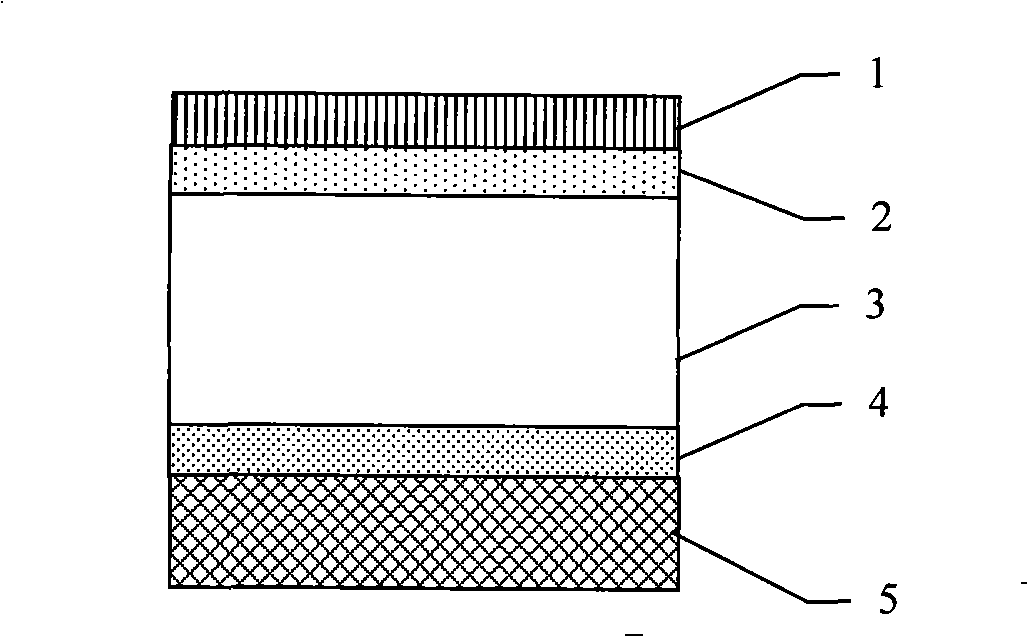

[0048] Embodiment 1. Fabrication and adjustment of device one (sapphire substrate / Au / white light device / Ag / Au)

[0049] The cathode and anode of device 1 are both metal, and the manufacturing process is as follows: the substrate is sapphire (of course, other substrates can also be selected), and then a layer of gold is deposited as the anode by vacuum thermal evaporation; The traditional white light organic electroluminescent device (that is, the active layer) is produced by thermal evaporation; and then a layer of silver and gold are respectively deposited as a composite cathode by vacuum thermal evaporation.

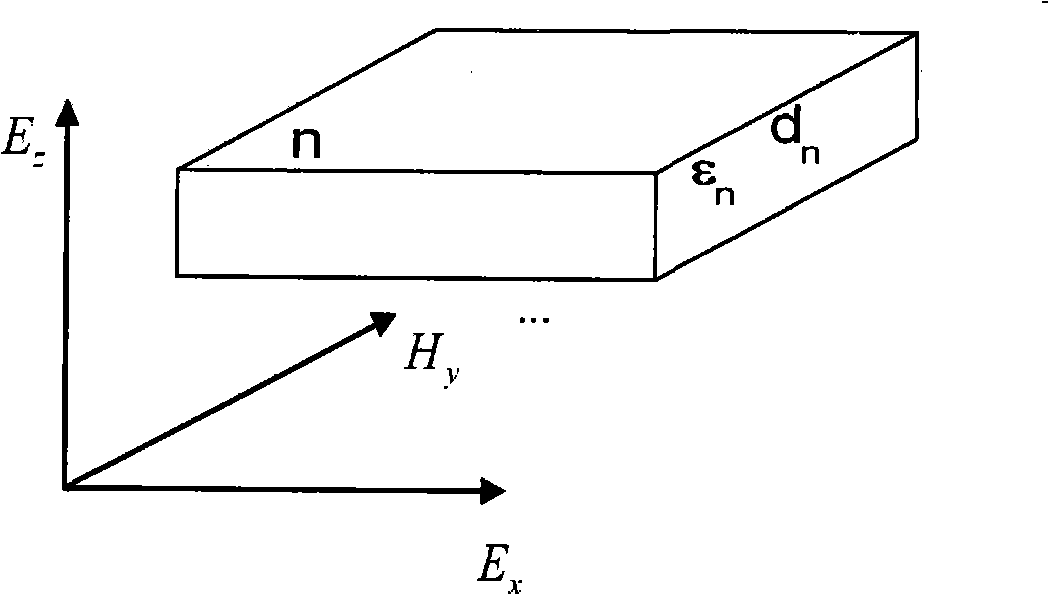

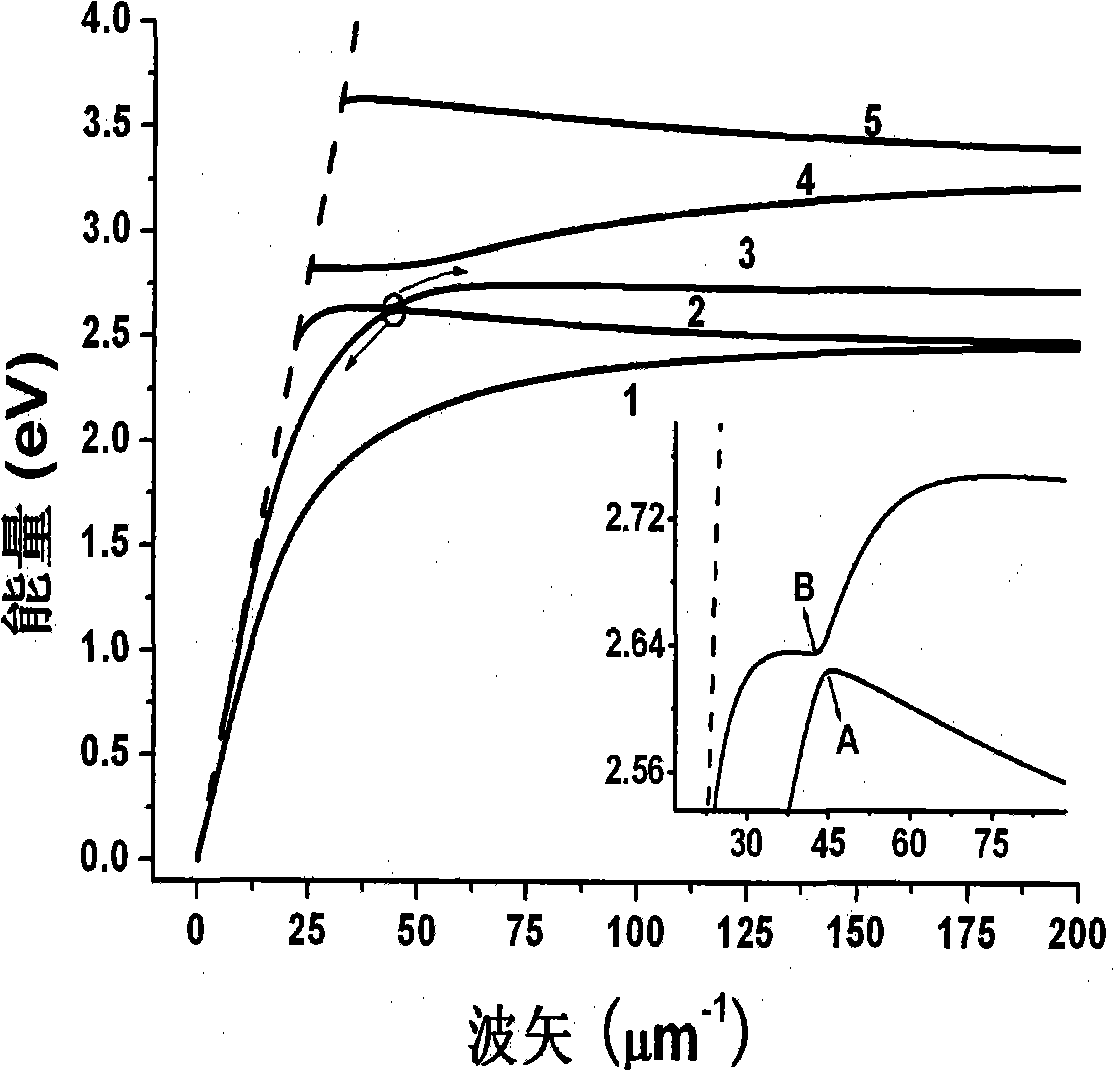

[0050] The device has five metal interfaces, so there are five surface plasmon dispersion branches. When the device parameters are: sapphire substrate / Au(20nm) / white light device (100nm) / Ag(10nm) / Au(10nm), get image 3 The surface plasmon dispersion curve is shown. image 3 The middle branches 1 and 2 are mainly determined by the metal anode, and the branches 3, 4 an...

Embodiment 2

[0051] Embodiment 2. Fabrication and adjustment of device two (sapphire substrate / Au / white light device / Ag / Au / GaP)

[0052] On the basis of device one, a cap layer is deposited on the composite cathode by sputtering to obtain device two. When the cap layer material is gallium phosphide (ε=12.4), and the thickness of each layer of the device is sapphire substrate / Au(10nm) / white light device (100nm) / Ag(20nm) / Au(10nm) / GaP(10nm), the device The surface plasmon dispersion curve of the second is as Figure 5 shown. Due to the addition of a high dielectric constant cap layer on the composite cathode silver and gold, the 3-branch of the cathode is depressed to the anti-cross coupling with the 1-branch of the anode. Depend on Figure 5 It can be seen that the wave vector of the two is about 79.18 μm -1 place where anti-cross-coupling occurs (see Figure 5 The partially enlarged inset in the lower right corner), the energy of this resonant plasmonic channel is 2.06 eV. By adjustin...

Embodiment 3

[0053] Embodiment 3. Fabrication and adjustment of device three (Si substrate / white light device / Ag / Au / GaP)

[0054] This example shows the operation of a device where only one electrode is metallic. At this time, the position of the luminescent excitons is required to be relatively close to the cathode.

[0055] When the position of the luminescent excitons is relatively close to the cathode (within 20nm), we can simply adjust the thickness of the cap layer above the cathode to achieve the transmission from red light to blue light.

[0056] Device manufacturing process: the substrate is selected as a silicon chip so as to be integrated with the existing silicon technology, and silicon also serves as an anode. Then use spin coating or vacuum thermal evaporation to fabricate traditional white light organic electroluminescent devices, then use thermal evaporation to deposit a layer of silver and gold as a composite cathode, and finally deposit a layer of silver on the cathode b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com