Production method of MgB2 block material doped with organic matter

An organic and organic technology, applied in the field of MgB2 superconducting material preparation, can solve the problems of increasing manufacturing costs, not being able to adapt to industrial production, and the high price of nano-sized particles, so as to increase the critical current density and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Weigh 2.764359g of Mg powder, 2.235641g of B powder and 0.5g of zinc polyacrylate powder respectively, add boron powder and zinc polyacrylate powder into deionized water, stir for 1h, then use an oven to completely evaporate the solvent, and mix with magnesium powder Fully mixed under Ar protective atmosphere;

[0024] 2) Put the uniformly mixed powder into a mould, press and form it with a press to obtain a block, the pressure is 14Mpa, and keep for 5min;

[0025] 3) Annealing and sintering the obtained bulk material under Ar protective atmosphere to obtain zinc polyacrylate doped MgB 2 Block material, the sintering process is as follows: from room temperature to 800 °C at a heating rate of 6 °C / min, after holding for 1 hour, cooling with the furnace to obtain polyacrylic acid zinc-doped MgB 2 blocks.

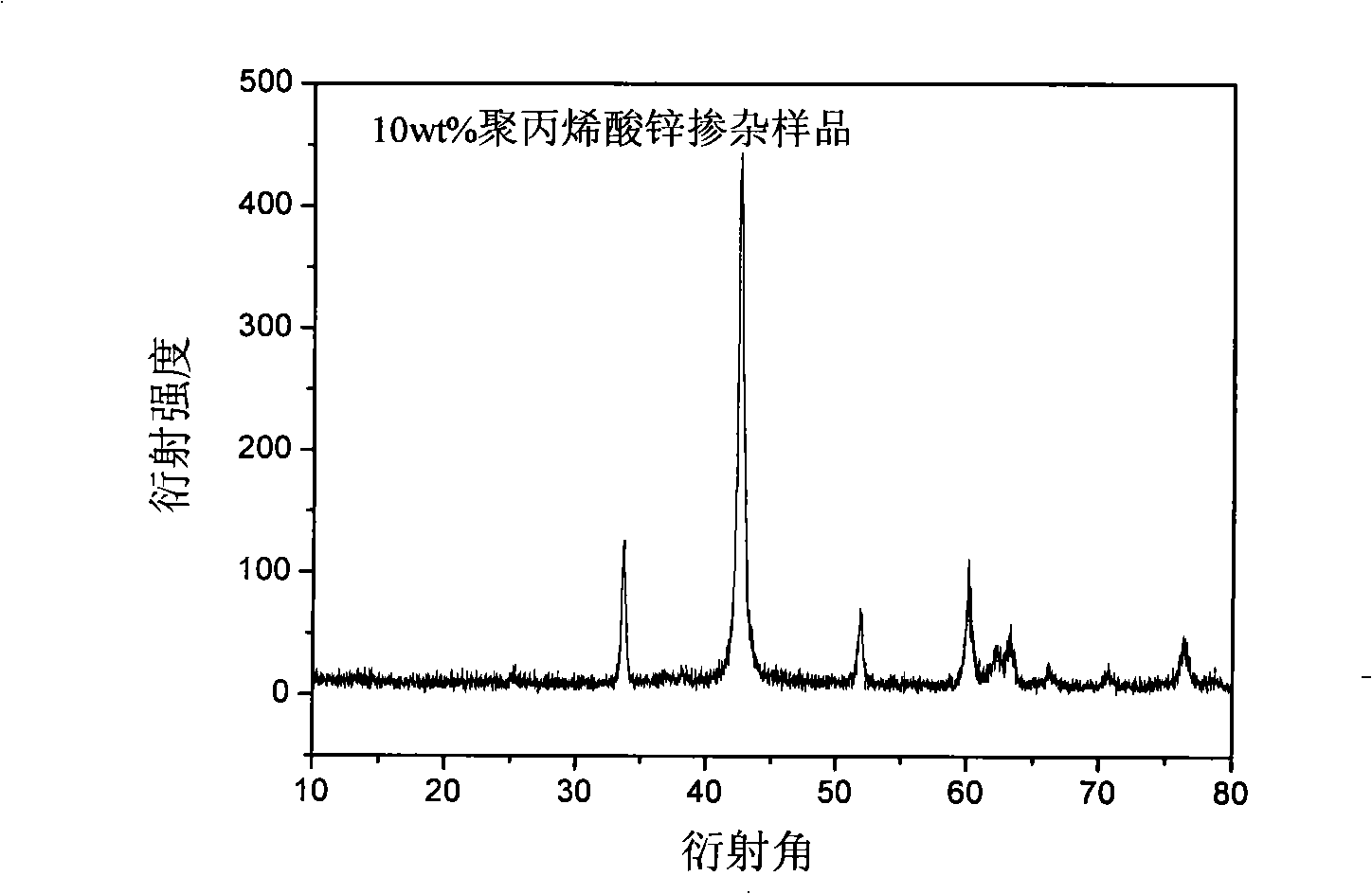

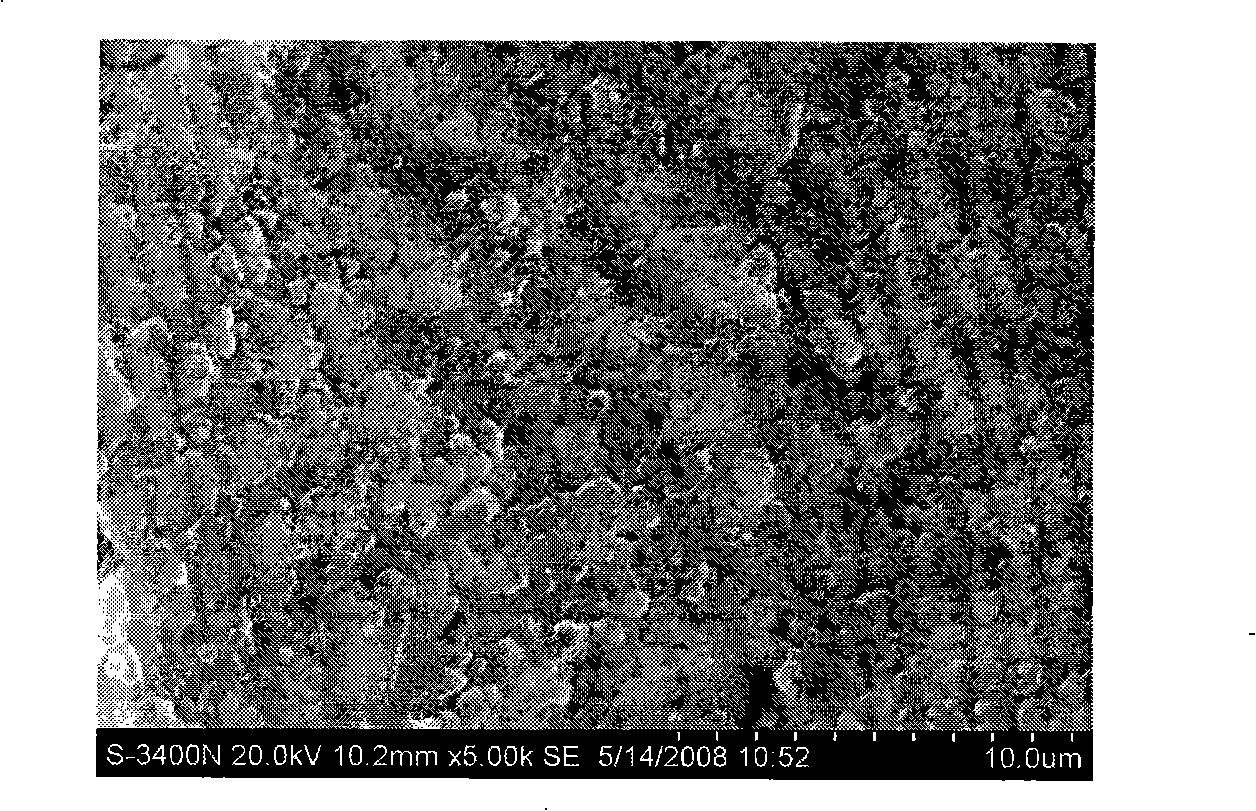

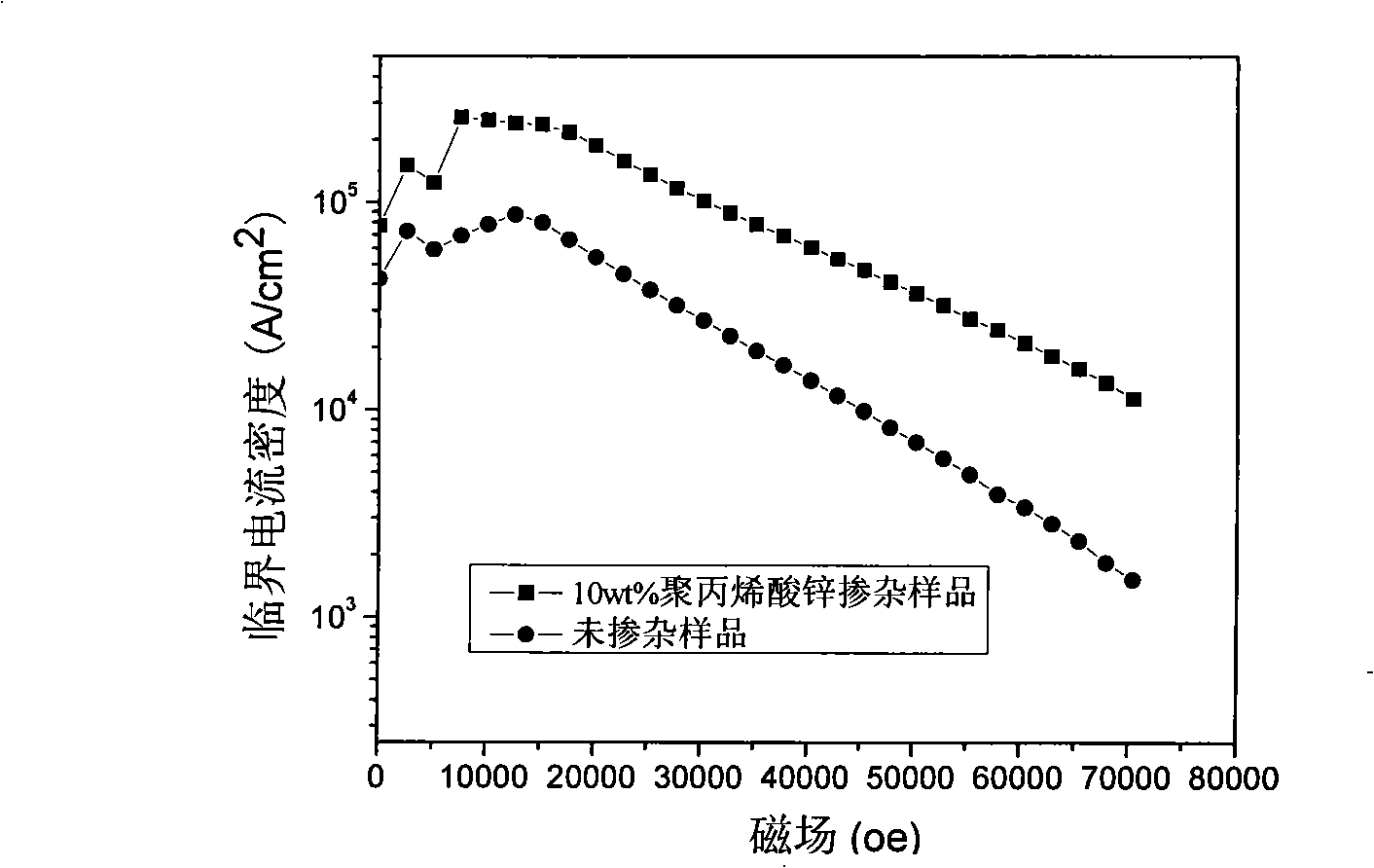

[0026] MgB 2 The XRD pattern of the sample is as figure 1 As shown, it can be seen that MgB is mainly generated in the reaction 2 Mutually. MgB 2 The fracture...

Embodiment 2

[0028] 1) Weigh 2.646047g of Mg powder, 2.353953g of B powder and 1g of zinc magnesium polyacrylate, add boron powder and magnesium polyacrylate powder into deionized water, stir for 1h, then use an oven to completely evaporate the solvent, and mix with magnesium powder in Fully mixed under Ar protective atmosphere;

[0029] 2) Put the uniformly mixed powder into a mould, press and form it with a press to obtain a block, the pressure is 14Mpa, and keep for 5min;

[0030] 3) Annealing and sintering the obtained bulk material under Ar protective atmosphere to obtain magnesium polyacrylate doped MgB 2 Block material, the sintering process is as follows: from room temperature to 900 °C at a heating rate of 6 °C / min, after holding for 1 hour, cooling with the furnace to obtain MgB doped with magnesium polyacrylate 2 blocks.

[0031] MgB 2 The XRD pattern of the sample is as Figure 5 As shown, it can be seen that MgB is mainly generated in the reaction 2 Mutually. Image 6 fo...

Embodiment 3

[0033] 1) Weigh 2.764359g of Mg powder, 2.235641g of B powder and 1.5g of zinc polyacrylate powder respectively, add boron powder and zinc polyacrylate powder into deionized water, stir for 1h, then use an oven to completely evaporate the solvent, and mix with magnesium powder Fully mixed under Ar protective atmosphere;

[0034] 2) the powder mixed homogeneously is packed in the mould, presses molding with press, and pressure is 14Mpa, keeps 5mi;

[0035] 3) Annealing and sintering the obtained bulk material under Ar protective atmosphere to obtain zinc polyacrylate doped MgB 2 Block material, the sintering process is as follows: from room temperature to 600 °C at a heating rate of 6 °C / min, after holding for 1 hour, cooling with the furnace to obtain polyacrylic acid zinc-doped MgB 2 blocks.

[0036] Figure 7for MgB 2 The critical current density of the sample varies with temperature, and the critical current density of the wire is calculated by the magnetic measurement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com