Method for preparing methyl hydride combustion catalyst

A methane combustion and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effects of high thermal stability, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

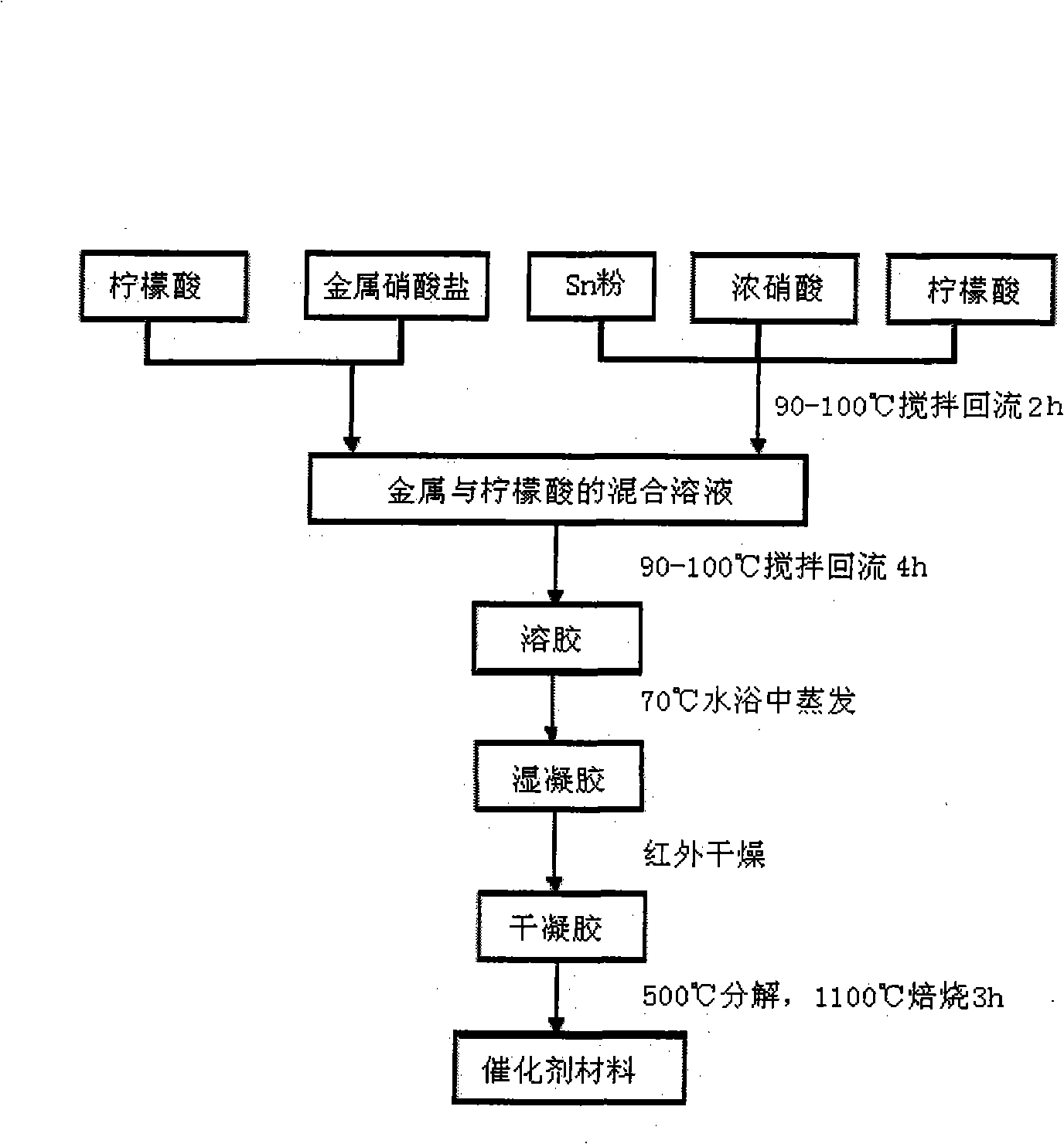

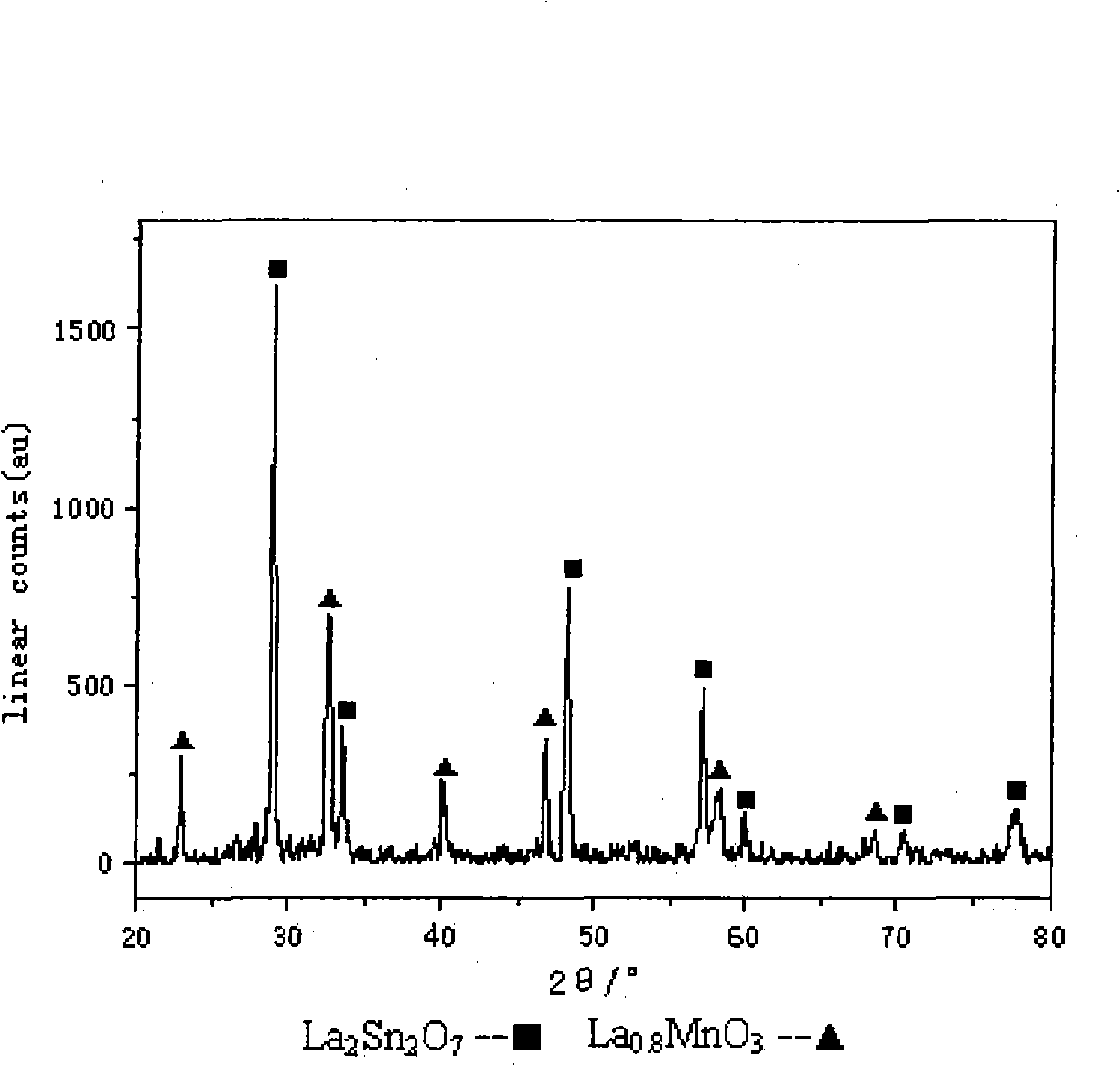

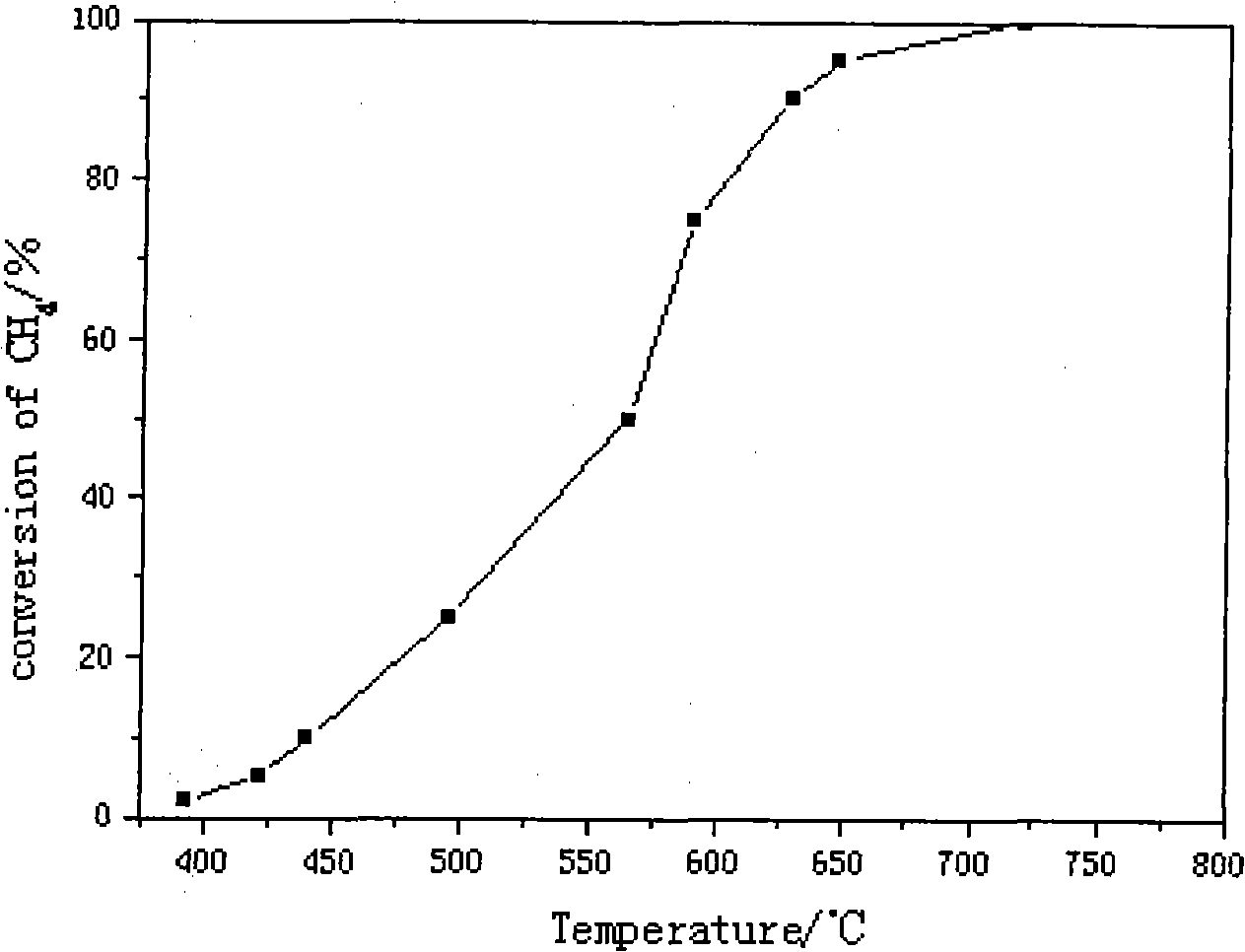

[0019] The present invention will be further described with a specific example below: take by weighing 3.56g Sn powder and be dissolved in 12mL mass fraction and be 32.5% nitric acid, take by weighing 6.30g citric acid and be mixed with the aqueous solution of 0.5mol / L, both mix, in Stir and reflux at 100°C for 2 hours; weigh 25.98g La(NO 3 ) 3 ·6H 2 O and 10.74g mass percent are 50% Mn(NO 3 ) 2The aqueous solution was mixed and dissolved in deionized water to make its concentration 0.5mol / L, and 18.90g of citric acid was weighed to prepare a 0.5mol / L aqueous solution, and the La(NO 3 ) 3 and Mn(NO 3 ) 2 The mixed aqueous solution was added to the citric acid solution to form a metal ion citric acid complex solution; the complex solution was added to the above-mentioned tin-containing citric acid solution, continued to stir and reflux for 4 hours, and transferred to a beaker in a constant temperature water bath at 70°C to evaporate into a wet The gel is dried in an infr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com